Polycarbonate PET offers exceptional optical clarity, making it ideal for applications requiring high transparency and minimal distortion. This material balances its superior impact resistance, providing durability and protection without compromising visual quality. Its unique blend ensures products remain clear and strong under various conditions, enhancing both performance and aesthetic appeal.

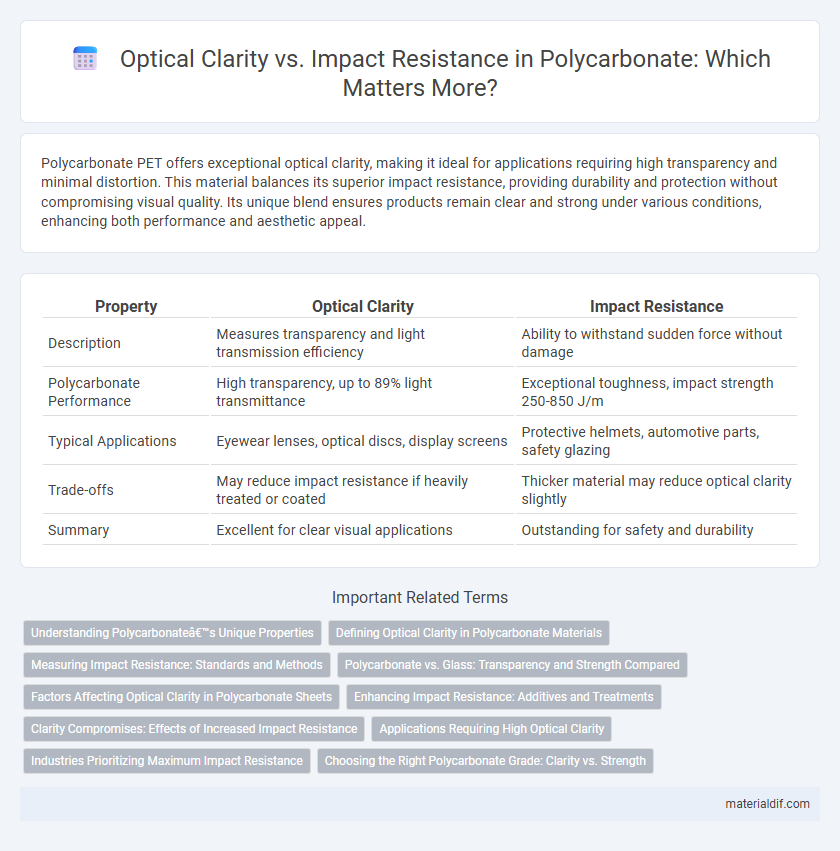

Table of Comparison

| Property | Optical Clarity | Impact Resistance |

|---|---|---|

| Description | Measures transparency and light transmission efficiency | Ability to withstand sudden force without damage |

| Polycarbonate Performance | High transparency, up to 89% light transmittance | Exceptional toughness, impact strength 250-850 J/m |

| Typical Applications | Eyewear lenses, optical discs, display screens | Protective helmets, automotive parts, safety glazing |

| Trade-offs | May reduce impact resistance if heavily treated or coated | Thicker material may reduce optical clarity slightly |

| Summary | Excellent for clear visual applications | Outstanding for safety and durability |

Understanding Polycarbonate’s Unique Properties

Polycarbonate exhibits exceptional optical clarity, allowing over 90% light transmission, making it ideal for lenses and transparent shields. Its molecular structure also provides remarkable impact resistance, with an impact strength around 250 times that of glass, offering superior durability in safety applications. This unique combination of transparency and toughness distinguishes polycarbonate in industries requiring both visibility and protection.

Defining Optical Clarity in Polycarbonate Materials

Optical clarity in polycarbonate refers to the material's ability to transmit light with minimal distortion and high transparency, ensuring clear visibility through the lens or sheet. This property is influenced by the polymer's molecular structure, absence of impurities, and surface finish, which collectively reduce haze and maximize light transmittance. High optical clarity is essential in applications like eyewear lenses, protective shields, and display covers, where visual performance and accurate color representation are critical.

Measuring Impact Resistance: Standards and Methods

Impact resistance of polycarbonate is measured using standardized tests such as ASTM D256 for the Izod impact test and ASTM D6110 for the Charpy impact test, which quantify the material's ability to absorb and dissipate energy upon impact. Instrumented impact testing and drop weight tests further provide precise metrics on fracture toughness and energy absorption specific to polycarbonate sheets and molded parts. These standardized methods ensure consistent evaluation of the balance between optical clarity and mechanical durability in polycarbonate materials.

Polycarbonate vs. Glass: Transparency and Strength Compared

Polycarbonate offers exceptional optical clarity with light transmittance around 90%, closely rivaling glass, which typically transmits about 92%. Unlike glass, polycarbonate exhibits superior impact resistance, being up to 250 times stronger, making it ideal for applications where safety and durability are critical. This combination of high transparency and unmatched strength positions polycarbonate as the preferred material for protective eyewear, automotive windows, and architectural glazing.

Factors Affecting Optical Clarity in Polycarbonate Sheets

Polycarbonate sheets maintain high optical clarity due to their inherent low haze and high light transmittance, typically above 88%, making them ideal for glazing applications. Factors affecting optical clarity include molecular weight distribution, presence of impurities, and processing conditions such as cooling rate and molding temperature, which can induce internal stresses and microbubbles. Surface treatments and coatings also influence clarity by reducing scratches and UV-induced yellowing, ensuring long-term transparency and performance.

Enhancing Impact Resistance: Additives and Treatments

Increasing impact resistance in polycarbonate involves incorporating additives such as rubber tougheners and impact modifiers, which improve the material's toughness without significantly compromising optical clarity. Surface treatments like UV coatings enhance durability by protecting against environmental stressors while maintaining transparency. These enhancements extend polycarbonate's usability in applications requiring both high optical clarity and robust impact resistance, such as safety eyewear and automotive glazing.

Clarity Compromises: Effects of Increased Impact Resistance

Polycarbonate's optical clarity often diminishes as impact resistance increases due to the addition of impact modifiers that introduce light scattering centers. These modifications can cause slight haze or reduced transparency, affecting the material's suitability for high-precision optical applications. Balancing clarity and toughness requires optimizing formulations to minimize clarity compromises while enhancing durability.

Applications Requiring High Optical Clarity

Polycarbonate offers exceptional optical clarity, making it ideal for applications such as eyewear lenses, optical discs, and transparent covers where visual precision is critical. Despite its high transparency, polycarbonate also provides substantial impact resistance, ensuring durability and safety in scenarios like protective visors and automotive glazing. This balance of clarity and toughness positions polycarbonate as a preferred material in industries demanding both visual performance and mechanical protection.

Industries Prioritizing Maximum Impact Resistance

Industries such as automotive, aerospace, and protective equipment manufacturing prioritize maximum impact resistance over optical clarity when selecting polycarbonate materials. High-impact polycarbonate grades ensure enhanced durability and safety in applications like vehicle headlamps, aircraft windows, and ballistic shields. These sectors demand materials that withstand harsh conditions and high force without compromising structural integrity.

Choosing the Right Polycarbonate Grade: Clarity vs. Strength

Polycarbonate grades vary significantly in optical clarity and impact resistance, requiring careful selection based on application needs. High-clarity polycarbonate sheets offer superior transparency with light transmittance often exceeding 90%, ideal for lenses and optical displays, while impact-resistant grades provide enhanced toughness and can withstand forces up to 900 J/m without cracking. Balancing these properties involves selecting grades like optical-grade polycarbonate for clarity-sensitive uses or impact-modified variants for protective applications demanding both strength and moderate transparency.

Optical Clarity vs Impact Resistance Infographic

materialdif.com

materialdif.com