Scratch-resistant polycarbonate offers enhanced durability by incorporating a hard coating that significantly reduces surface abrasions compared to non-coated polycarbonate, which is more prone to visible scratches and wear. This coating preserves optical clarity and extends the lifespan of polycarbonate products, making it ideal for high-use applications like eyewear lenses and protective screens. Choosing scratch-resistant polycarbonate ensures better long-term performance and aesthetic maintenance without compromising impact resistance.

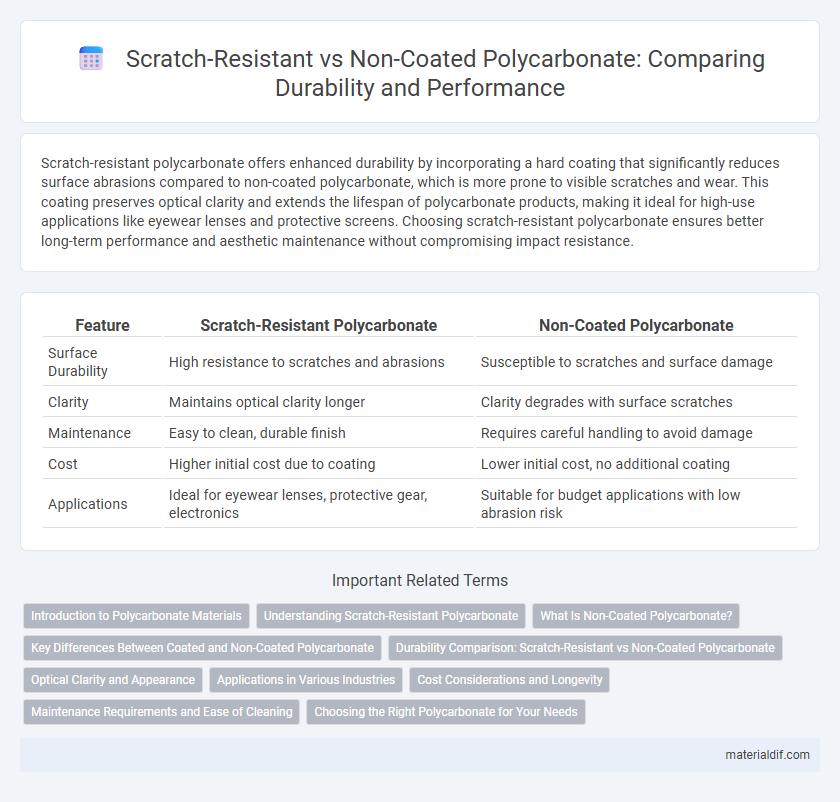

Table of Comparison

| Feature | Scratch-Resistant Polycarbonate | Non-Coated Polycarbonate |

|---|---|---|

| Surface Durability | High resistance to scratches and abrasions | Susceptible to scratches and surface damage |

| Clarity | Maintains optical clarity longer | Clarity degrades with surface scratches |

| Maintenance | Easy to clean, durable finish | Requires careful handling to avoid damage |

| Cost | Higher initial cost due to coating | Lower initial cost, no additional coating |

| Applications | Ideal for eyewear lenses, protective gear, electronics | Suitable for budget applications with low abrasion risk |

Introduction to Polycarbonate Materials

Polycarbonate is a durable thermoplastic known for its high impact resistance and optical clarity, widely used in eyewear lenses, automotive components, and electronic displays. Scratch-resistant polycarbonate incorporates a hard coating that significantly enhances surface durability, preventing abrasion and maintaining clarity over time compared to non-coated polycarbonate. Non-coated polycarbonate, while inherently strong, is more susceptible to surface damage, which can compromise transparency and longevity in demanding applications.

Understanding Scratch-Resistant Polycarbonate

Scratch-resistant polycarbonate features a specialized coating that significantly enhances durability by preventing surface abrasions and maintaining optical clarity. This coating extends the lifespan of polycarbonate lenses and panels, reducing the need for frequent replacements compared to non-coated polycarbonate. Understanding the science behind scratch-resistant treatments reveals their crucial role in preserving product aesthetics and functionality in demanding environments.

What Is Non-Coated Polycarbonate?

Non-coated polycarbonate is a versatile thermoplastic material known for its impact resistance and optical clarity but lacks a protective layer against surface abrasions. Unlike scratch-resistant polycarbonate, non-coated variants are more prone to visible damage from everyday wear and tear, reducing their longevity in high-use applications. This inherent vulnerability necessitates frequent replacements or additional protective measures in environments demanding durability.

Key Differences Between Coated and Non-Coated Polycarbonate

Scratch-resistant polycarbonate features a durable, transparent coating that significantly enhances surface hardness, reducing the likelihood of scratches compared to non-coated polycarbonate. Non-coated polycarbonate is more susceptible to abrasion and surface damage, limiting its lifespan and clarity in applications prone to frequent contact or impact. The coating also improves UV resistance and maintains optical clarity, making scratch-resistant polycarbonate ideal for high-wear environments such as safety glasses, automotive parts, and electronic displays.

Durability Comparison: Scratch-Resistant vs Non-Coated Polycarbonate

Scratch-resistant polycarbonate features a durable coating that significantly enhances surface hardness, reducing the likelihood of scratches and abrasions compared to non-coated polycarbonate. Non-coated polycarbonate, while naturally impact-resistant and lightweight, is more susceptible to surface damage and wear over time, especially in high-contact environments. The scratch-resistant variant extends the lifespan and maintains clarity, making it ideal for applications requiring prolonged visual and structural integrity.

Optical Clarity and Appearance

Scratch-resistant polycarbonate maintains superior optical clarity by preventing surface abrasions that cause visual distortions, unlike non-coated polycarbonate which is prone to scratches that degrade transparency over time. The specialized hard coating enhances durability without compromising the material's inherent high light transmission and clarity. In applications where appearance and long-term visibility are critical, scratch-resistant polycarbonate offers a significantly clearer and more aesthetically pleasing solution.

Applications in Various Industries

Scratch-resistant polycarbonate offers enhanced durability and longevity, making it ideal for applications in automotive, aerospace, and electronic device manufacturing where surface integrity is critical. Non-coated polycarbonate, while more cost-effective, is prone to abrasion and scratching, limiting its use in high-wear environments such as protective eyewear or industrial safety equipment. Industries requiring clear, impact-resistant materials with sustained optical clarity benefit significantly from scratch-resistant polycarbonate coatings.

Cost Considerations and Longevity

Scratch-resistant polycarbonate typically involves a higher initial cost due to advanced coating technologies designed to enhance durability and maintain clarity over time. Non-coated polycarbonate, while more affordable upfront, tends to degrade faster with visible scratches that compromise both appearance and performance. Investing in scratch-resistant coatings often reduces replacement frequency, providing better long-term value despite the higher starting price.

Maintenance Requirements and Ease of Cleaning

Scratch-resistant polycarbonate significantly reduces surface abrasions, making maintenance less frequent and cleaning more efficient compared to non-coated polycarbonate. The protective coating minimizes micro-scratches caused by dust or cleaning tools, preserving clarity and extending product lifespan. Non-coated polycarbonate requires gentler cleaning methods and more frequent maintenance to avoid permanent damage and maintain optical quality.

Choosing the Right Polycarbonate for Your Needs

Scratch-resistant polycarbonate offers enhanced durability by incorporating a hard coating that significantly reduces surface abrasions, making it ideal for applications requiring high clarity and longevity. Non-coated polycarbonate, while more affordable, is prone to scratches and may degrade in appearance over time, limiting its suitability for visually critical or high-wear environments. Selecting the right polycarbonate depends on balancing cost, durability requirements, and the intended application's exposure to physical wear or environmental stress.

Scratch-Resistant Polycarbonate vs Non-Coated Polycarbonate Infographic

materialdif.com

materialdif.com