Optical-grade polycarbonate offers superior clarity, light transmission, and minimal distortion, making it ideal for applications such as eyewear lenses and optical devices. Industrial-grade polycarbonate prioritizes durability and impact resistance over optical properties, suitable for construction, automotive, and protective equipment. Choosing between these grades depends on the balance needed between visual quality and mechanical strength in your project.

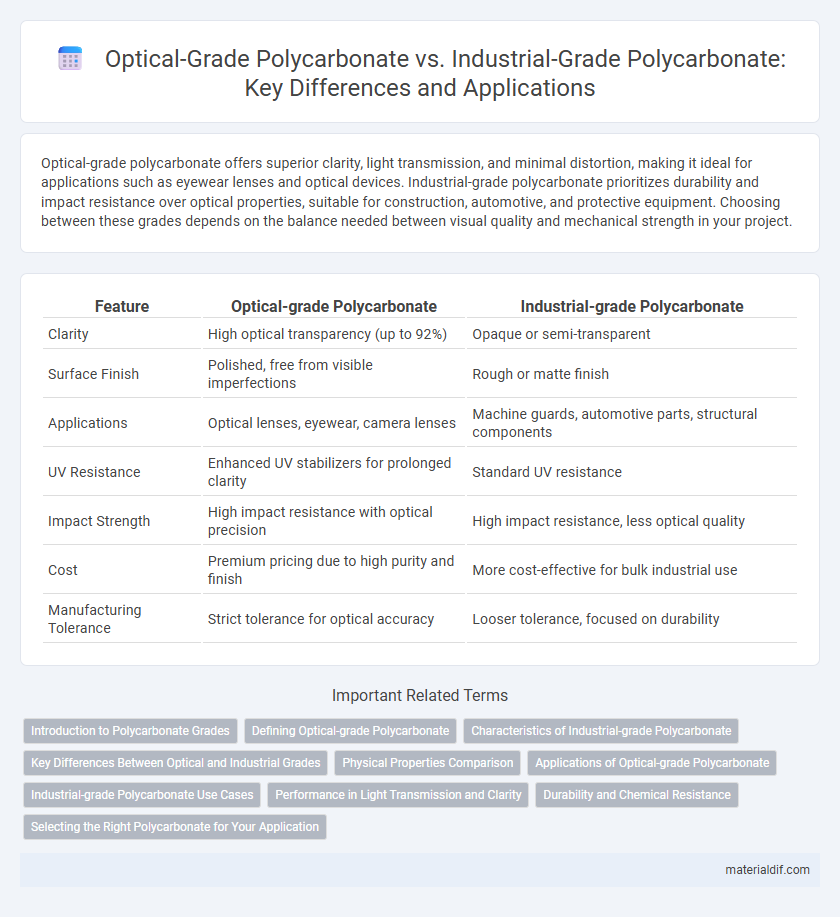

Table of Comparison

| Feature | Optical-grade Polycarbonate | Industrial-grade Polycarbonate |

|---|---|---|

| Clarity | High optical transparency (up to 92%) | Opaque or semi-transparent |

| Surface Finish | Polished, free from visible imperfections | Rough or matte finish |

| Applications | Optical lenses, eyewear, camera lenses | Machine guards, automotive parts, structural components |

| UV Resistance | Enhanced UV stabilizers for prolonged clarity | Standard UV resistance |

| Impact Strength | High impact resistance with optical precision | High impact resistance, less optical quality |

| Cost | Premium pricing due to high purity and finish | More cost-effective for bulk industrial use |

| Manufacturing Tolerance | Strict tolerance for optical accuracy | Looser tolerance, focused on durability |

Introduction to Polycarbonate Grades

Optical-grade polycarbonate offers high light transmittance, exceptional clarity, and minimal birefringence, making it ideal for lenses, eyewear, and optical components. Industrial-grade polycarbonate prioritizes impact resistance, durability, and thermal stability, commonly used in automotive parts, electronic housings, and construction materials. Understanding these grade-specific properties enables precise material selection for applications requiring either superior optical performance or robust mechanical strength.

Defining Optical-grade Polycarbonate

Optical-grade polycarbonate is characterized by its superior clarity, high light transmittance above 90%, and minimal optical distortion, making it ideal for lenses, eyeglasses, and optical displays. Unlike industrial-grade polycarbonate, which is designed primarily for impact resistance and durability, optical-grade materials undergo precise manufacturing controls to ensure uniform refractive index and surface smoothness. Key specifications include low birefringence, high UV resistance, and excellent dimensional stability, fulfilling stringent optical performance standards.

Characteristics of Industrial-grade Polycarbonate

Industrial-grade polycarbonate offers high impact resistance and excellent dimensional stability, making it suitable for demanding applications such as automotive parts and protective equipment. It typically exhibits lower optical clarity compared to optical-grade polycarbonate but provides superior thermal resistance and durability under harsh environmental conditions. This grade emphasizes mechanical strength and cost-efficiency over transparency, catering to industrial uses where toughness and performance are critical.

Key Differences Between Optical and Industrial Grades

Optical-grade polycarbonate offers superior clarity and light transmission, making it ideal for lenses, eyewear, and optical components, while industrial-grade polycarbonate prioritizes impact resistance and durability for applications like machine guards and construction materials. Optical-grade polycarbonate undergoes stricter quality control processes to minimize defects and ensure consistent optical performance, whereas industrial grade focuses on robustness and cost efficiency. Differences in UV resistance and surface finish further distinguish optical-grade polycarbonate, which features enhanced coatings to prevent yellowing and scratching compared to its industrial counterpart.

Physical Properties Comparison

Optical-grade polycarbonate exhibits superior light transmittance, clarity above 89%, and minimal haze, making it ideal for precision optical applications. Industrial-grade polycarbonate offers enhanced impact resistance and higher thermal stability, suitable for rugged environments but with lower optical clarity around 85%. Both grades share similar tensile strength, approximately 60 MPa, but differ significantly in surface finish and optical uniformity.

Applications of Optical-grade Polycarbonate

Optical-grade polycarbonate is primarily used in applications requiring high transparency and optical clarity, such as eyewear lenses, medical devices, and optical discs. Its superior light transmission and resistance to UV rays make it ideal for precision instruments and safety visors. Industrial-grade polycarbonate, by contrast, is better suited for structural components, automotive parts, and protective enclosures where mechanical strength outweighs optical properties.

Industrial-grade Polycarbonate Use Cases

Industrial-grade polycarbonate is widely used in applications requiring high impact resistance and durability, such as machine guards, automotive components, and electrical enclosures. Its ability to withstand harsh environmental conditions makes it ideal for outdoor signage and protective equipment. The material's cost-effectiveness compared to optical-grade polycarbonate supports extensive use in manufacturing and construction industries.

Performance in Light Transmission and Clarity

Optical-grade polycarbonate exhibits superior light transmission rates of up to 90%, ensuring high clarity and minimal distortion ideal for lenses and transparent components. In contrast, industrial-grade polycarbonate typically offers lower light transmission around 85%, with a slight haze due to additives and less stringent manufacturing controls. The enhanced optical purity and precise polymerization process in optical-grade polycarbonate result in clearer, brighter materials essential for applications requiring excellent visual performance.

Durability and Chemical Resistance

Optical-grade polycarbonate exhibits superior clarity and is engineered with enhanced impact resistance, making it highly durable for precision applications such as lenses and protective eyewear. Industrial-grade polycarbonate offers robust chemical resistance and structural strength tailored for harsh environments, including automotive and electrical components. Both grades maintain excellent durability, but optical-grade emphasizes optical performance while industrial-grade prioritizes chemical stability and mechanical toughness.

Selecting the Right Polycarbonate for Your Application

Optical-grade polycarbonate offers superior clarity, light transmission above 88%, and excellent UV resistance, making it ideal for applications like eyewear lenses and medical devices requiring precise visual performance. Industrial-grade polycarbonate prioritizes impact resistance and toughness with slightly lower optical clarity, suitable for protective gear, automotive parts, and construction materials. Selecting the right polycarbonate depends on balancing optical properties and mechanical strength based on the specific functional demands of your application.

Optical-grade Polycarbonate vs Industrial-grade Polycarbonate Infographic

materialdif.com

materialdif.com