Polycarbonate flame retardant grade offers enhanced fire resistance by incorporating flame retardant additives, making it suitable for applications requiring higher safety standards. In contrast, non-flame retardant grade lacks these additives, resulting in lower ignition resistance and limited use in environments with strict fire safety regulations. Choosing between the two depends on the specific requirements for heat tolerance and regulatory compliance in the intended application.

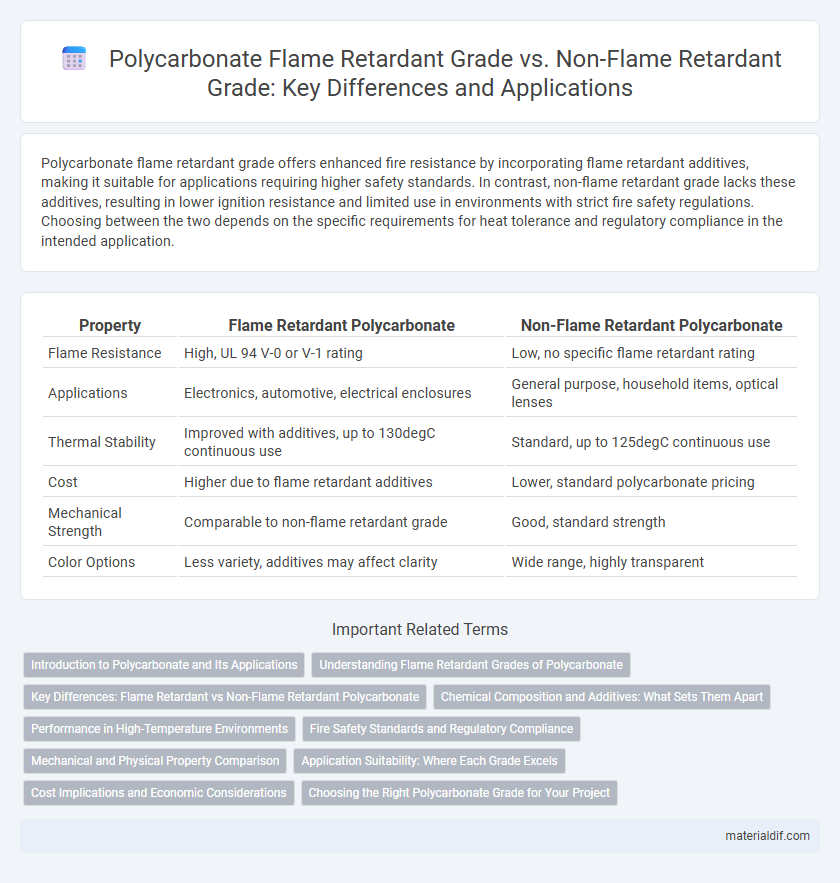

Table of Comparison

| Property | Flame Retardant Polycarbonate | Non-Flame Retardant Polycarbonate |

|---|---|---|

| Flame Resistance | High, UL 94 V-0 or V-1 rating | Low, no specific flame retardant rating |

| Applications | Electronics, automotive, electrical enclosures | General purpose, household items, optical lenses |

| Thermal Stability | Improved with additives, up to 130degC continuous use | Standard, up to 125degC continuous use |

| Cost | Higher due to flame retardant additives | Lower, standard polycarbonate pricing |

| Mechanical Strength | Comparable to non-flame retardant grade | Good, standard strength |

| Color Options | Less variety, additives may affect clarity | Wide range, highly transparent |

Introduction to Polycarbonate and Its Applications

Polycarbonate flame retardant grade offers enhanced fire resistance properties compared to the non-flame retardant grade, making it ideal for safety-critical applications in electronics, automotive, and construction industries. Non-flame retardant polycarbonate maintains excellent impact strength and optical clarity but lacks the fire safety features required for regulated environments. The choice between these grades depends on balancing performance needs with compliance for fire safety standards.

Understanding Flame Retardant Grades of Polycarbonate

Flame retardant grades of polycarbonate are specially formulated to enhance fire resistance by incorporating additives that inhibit ignition and slow flame spread, meeting stringent safety standards such as UL 94 V-0. Non-flame retardant polycarbonate lacks these additives, making it more susceptible to combustion and limiting its use in applications requiring strict fire safety compliance. Selecting the appropriate grade depends on application requirements, regulatory mandates, and performance criteria in environments exposed to high temperatures or potential fire hazards.

Key Differences: Flame Retardant vs Non-Flame Retardant Polycarbonate

Flame retardant polycarbonate grades contain specific additives like brominated compounds or phosphorus-based agents that significantly enhance fire resistance by reducing flammability and smoke generation during combustion. Non-flame retardant polycarbonate lacks these additives, offering higher optical clarity and impact resistance but failing to meet stringent fire safety standards required in electrical, automotive, or construction applications. The primary distinction lies in their thermal stability and compliance with fire safety regulations such as UL 94 V-0 versus the typical UL 94 HB rating for non-flame retardant grades.

Chemical Composition and Additives: What Sets Them Apart

Polycarbonate flame retardant grades contain specific chemical additives such as brominated compounds or phosphorus-based flame retardants that inhibit ignition and reduce flame propagation, unlike non-flame retardant grades which lack these components. The inclusion of additives like antimony trioxide enhances the synergistic effect, boosting flame resistance without compromising the polymer's mechanical properties. Non-flame retardant polycarbonate primarily consists of base polymer chains with minimal additives, resulting in higher flammability and faster combustion under heat exposure.

Performance in High-Temperature Environments

Polycarbonate flame retardant grades exhibit superior thermal stability and maintain mechanical integrity at elevated temperatures up to 150degC, compared to non-flame retardant grades that typically soften and deform above 130degC. The flame retardant additives enhance resistance to ignition and reduce combustion heat release, making these grades suitable for high-temperature electrical and automotive applications. Non-flame retardant polycarbonates may compromise safety and performance under sustained heat exposure, limiting their use in critical high-temperature environments.

Fire Safety Standards and Regulatory Compliance

Polycarbonate flame retardant grade is engineered to meet stringent fire safety standards such as UL 94 V-0 and EN 13501-1, ensuring rapid self-extinguishing properties and reduced smoke emissions. Non-flame retardant polycarbonate lacks these certifications, limiting its use in applications requiring regulatory compliance for fire resistance. Regulatory bodies mandate flame retardant grades for construction, electrical, and transportation industries to mitigate fire hazards and enhance occupant safety.

Mechanical and Physical Property Comparison

Polycarbonate flame retardant grades exhibit enhanced fire resistance while maintaining mechanical strength, with tensile strength typically ranging from 60 to 70 MPa, slightly lower than the 65 to 75 MPa found in non-flame retardant grades. Impact resistance in flame retardant polycarbonate often measures around 700 to 900 J/m, compared to higher values up to 1000 J/m in standard grades, reflecting the trade-off between flame retardancy and toughness. Physical properties such as thermal stability improve significantly in flame retardant grades, with heat deflection temperatures reaching up to 140degC versus approximately 130degC in non-flame retardant variants.

Application Suitability: Where Each Grade Excels

Polycarbonate flame retardant grade excels in electrical and electronic housings, automotive interiors, and aerospace components where stringent fire safety standards are mandatory. Non-flame retardant grade is better suited for applications like consumer goods, optical lenses, and medical devices where high clarity and impact resistance matter more than fire resistance. Choosing the right grade depends on the specific requirements of fire safety compliance and mechanical performance in the intended application.

Cost Implications and Economic Considerations

Polycarbonate flame retardant grade typically incurs higher material costs due to the incorporation of flame retardant additives and the need for specialized manufacturing processes that ensure compliance with stringent fire safety standards. Non-flame retardant grades offer cost advantages in applications where fire resistance is not critical, resulting in lower raw material and processing expenses. Economic considerations must balance the premium price of flame retardant polycarbonate against potential liabilities and regulatory requirements in safety-critical environments.

Choosing the Right Polycarbonate Grade for Your Project

Polycarbonate flame retardant grade offers enhanced fire resistance, making it ideal for applications requiring strict safety standards such as electrical enclosures, automotive components, and construction materials. Non-flame retardant polycarbonate provides excellent impact strength and clarity but lacks the fire resistance necessary for regulated environments. Selecting the right polycarbonate grade depends on project-specific requirements for fire safety, mechanical performance, and regulatory compliance.

Polycarbonate flame retardant grade vs Non-flame retardant grade Infographic

materialdif.com

materialdif.com