Polycarbonate PET offers a balance between optical clarity and diffused transparency, allowing for versatile applications in both clear and matte finishes. Optical clarity provides sharp, vivid visibility ideal for protective shields and display cases, while diffused transparency scatters light to reduce glare and enhance privacy. This material's adaptability makes it suitable for environments requiring both aesthetic appeal and functional light management.

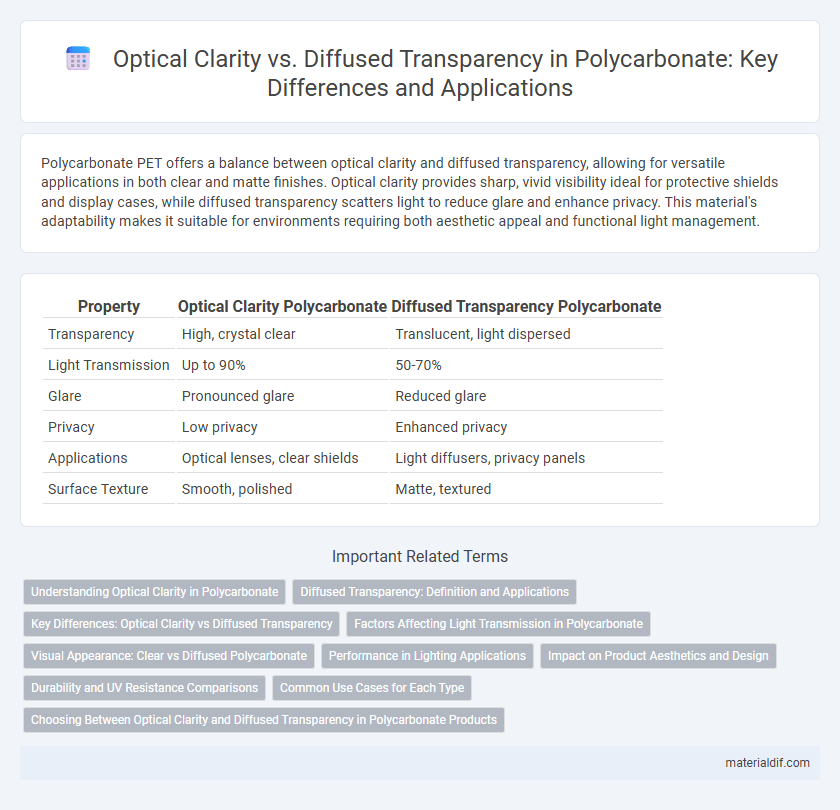

Table of Comparison

| Property | Optical Clarity Polycarbonate | Diffused Transparency Polycarbonate |

|---|---|---|

| Transparency | High, crystal clear | Translucent, light dispersed |

| Light Transmission | Up to 90% | 50-70% |

| Glare | Pronounced glare | Reduced glare |

| Privacy | Low privacy | Enhanced privacy |

| Applications | Optical lenses, clear shields | Light diffusers, privacy panels |

| Surface Texture | Smooth, polished | Matte, textured |

Understanding Optical Clarity in Polycarbonate

Optical clarity in polycarbonate is characterized by its high light transmission and minimal haze, allowing objects behind the material to be seen with precision and sharpness. This property is critical for applications such as eyewear lenses, safety visors, and optical discs where clear, undistorted vision is essential. In contrast, diffused transparency scatters light, creating a frosted effect that reduces glare but compromises the visibility of details through the material.

Diffused Transparency: Definition and Applications

Diffused transparency in polycarbonate refers to the material's ability to scatter light passing through it, resulting in a frosted or opaque appearance that obscures direct visibility while allowing illumination. This property is ideal for applications requiring privacy without sacrificing light transmission, such as skylights, privacy windows, and light panels in commercial and residential buildings. Polycarbonate diffused panels also enhance safety by reducing glare and UV exposure, making them suitable for automotive parts and electronic display covers.

Key Differences: Optical Clarity vs Diffused Transparency

Polycarbonate with optical clarity allows maximum light transmission and visual sharpness, making it ideal for applications requiring clear visibility, such as eyewear lenses and protective shields. Diffused transparency in polycarbonate scatters light, reducing glare and providing privacy while maintaining translucency, which is beneficial for lighting covers and architectural panels. The key difference lies in light behavior: optical clarity offers crisp, undistorted vision, whereas diffused transparency softens light and obscures detailed views.

Factors Affecting Light Transmission in Polycarbonate

Polycarbonate's light transmission is influenced by factors such as surface texture, thickness, and additives, which determine optical clarity or diffused transparency. Smooth, polished surfaces and thinner sheets enhance optical clarity by allowing more direct light passage, while textured or frosted finishes scatter light, creating diffused transparency. Incorporating UV stabilizers or colorants can further modify light absorption and scattering properties, impacting overall transparency quality.

Visual Appearance: Clear vs Diffused Polycarbonate

Polycarbonate's optical clarity delivers a glass-like transparency with minimal light distortion, making it ideal for applications requiring sharp visual detail and high light transmission. In contrast, diffused polycarbonate scatters light to reduce glare and enhance privacy, resulting in a frosted or opaque appearance that softens the visual output. Choosing between clear and diffused polycarbonate depends on the desired balance between direct visibility and light diffusion in architectural or protective applications.

Performance in Lighting Applications

Polycarbonate offers superior optical clarity, ensuring high light transmission and precise illumination in lighting applications. Its ability to maintain transparency without yellowing under prolonged UV exposure enhances performance in environments requiring consistent brightness. Diffused transparency variants of polycarbonate optimize light diffusion, reducing glare and creating uniform light distribution ideal for LED fixtures and architectural lighting.

Impact on Product Aesthetics and Design

Polycarbonate's optical clarity provides sharp, vivid visuals that enhance product aesthetics with a premium, glass-like appearance, while diffused transparency offers a softened light transmission that reduces glare and hides internal components for a sleek, modern design. Clear polycarbonate surfaces emphasize precise detail and color accuracy, ideal for products requiring high visual fidelity, whereas diffused variants support ambient light distribution and subtlety in design. Choosing between these transparency types directly influences the product's visual appeal, user experience, and brand perception in applications ranging from consumer electronics to automotive lighting.

Durability and UV Resistance Comparisons

Polycarbonate offers exceptional optical clarity with minimal light distortion, ensuring transparent visibility, whereas diffused transparency scatters light to reduce glare but lowers visual sharpness. In terms of durability, polycarbonate is highly resistant to impact and can withstand significant wear and tear, making it suitable for demanding environments. Polycarbonate's UV resistance is enhanced with special coatings that prevent yellowing and degradation, whereas materials with diffused transparency may lose optical properties faster under prolonged UV exposure.

Common Use Cases for Each Type

Polycarbonate with optical clarity is commonly used in applications requiring high transparency and precise visibility, such as lenses, protective eyewear, and greenhouse panels. Diffused transparency polycarbonate is preferred for lighting fixtures, privacy screens, and architectural partitions where light diffusion reduces glare and enhances privacy. Each type balances light transmission and diffusion to suit specific functional needs in industrial and consumer products.

Choosing Between Optical Clarity and Diffused Transparency in Polycarbonate Products

Choosing between optical clarity and diffused transparency in polycarbonate products depends on the desired visual effect and application requirements. Optical clarity polycarbonate offers high light transmission and minimal distortion, ideal for lenses and protective covers needing clear visibility. Diffused transparency polycarbonate scatters light to reduce glare and enhance privacy, making it suitable for lighting fixtures and privacy panels.

Optical clarity vs Diffused transparency Infographic

materialdif.com

materialdif.com