Abrasion resistant polycarbonate offers significantly enhanced durability compared to standard polycarbonate, making it ideal for applications exposed to frequent contact or harsh environments. This specialized material features a hard coating that protects against scratches and surface damage, extending the lifespan and maintaining clarity. Standard polycarbonate, while impact-resistant, is more prone to surface wear, limiting its use where abrasion resistance is critical.

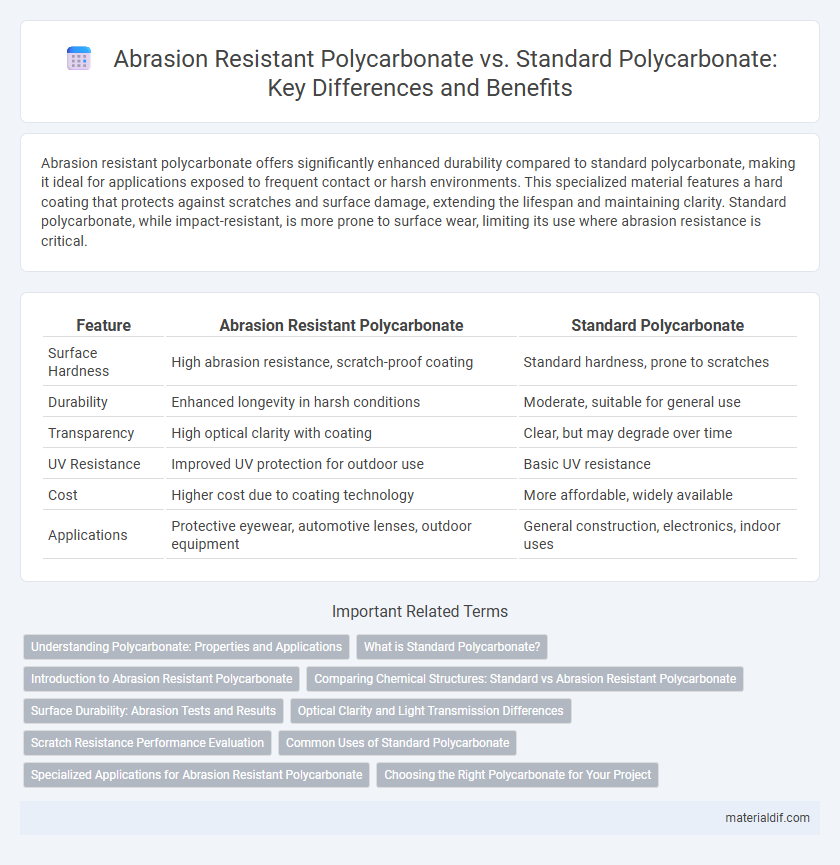

Table of Comparison

| Feature | Abrasion Resistant Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Surface Hardness | High abrasion resistance, scratch-proof coating | Standard hardness, prone to scratches |

| Durability | Enhanced longevity in harsh conditions | Moderate, suitable for general use |

| Transparency | High optical clarity with coating | Clear, but may degrade over time |

| UV Resistance | Improved UV protection for outdoor use | Basic UV resistance |

| Cost | Higher cost due to coating technology | More affordable, widely available |

| Applications | Protective eyewear, automotive lenses, outdoor equipment | General construction, electronics, indoor uses |

Understanding Polycarbonate: Properties and Applications

Abrasion resistant polycarbonate features a specialized coating that significantly enhances surface hardness and scratch resistance compared to standard polycarbonate, making it ideal for demanding applications like safety goggles, automotive parts, and protective screens. Standard polycarbonate offers excellent impact resistance, optical clarity, and lightweight properties, widely used in eyewear lenses, electronic components, and architectural glazing. Understanding these material differences helps select the appropriate polycarbonate type for specific performance requirements in industrial and consumer applications.

What is Standard Polycarbonate?

Standard polycarbonate is a durable, transparent thermoplastic known for its high impact resistance and optical clarity, commonly used in eyewear, automotive parts, and electronic components. It possesses excellent dimensional stability and thermal resistance but has a moderate susceptibility to surface scratches and abrasions. This makes it ideal for applications where toughness is critical but additional surface protection is not essential.

Introduction to Abrasion Resistant Polycarbonate

Abrasion resistant polycarbonate is engineered with a specialized surface coating that significantly enhances its durability against scratches and surface wear compared to standard polycarbonate. This improvement maintains the material's optical clarity and impact resistance, making it ideal for applications in eyewear lenses, protective shields, and automotive components. The abrasion resistant layer extends product lifespan and reduces maintenance costs in environments prone to frequent contact or abrasive elements.

Comparing Chemical Structures: Standard vs Abrasion Resistant Polycarbonate

Abrasion resistant polycarbonate incorporates specialized surface treatments and modified polymer chains that enhance hardness and reduce surface wear compared to standard polycarbonate, which consists primarily of bisphenol A-based aromatic carbonate linkages. The chemical structure of abrasion resistant variants often includes cross-linked segments or protective coatings, improving resistance to scratches and chemicals without significantly altering the core polymer backbone. Standard polycarbonate's molecular arrangement provides excellent impact resistance but is more susceptible to surface abrasion due to its relatively softer and less cross-linked polymer matrix.

Surface Durability: Abrasion Tests and Results

Abrasion resistant polycarbonate exhibits significantly higher surface durability compared to standard polycarbonate, as demonstrated by industry-standard abrasion tests such as the Taber Abrasion Test and sand slurry testing. These tests reveal that abrasion resistant variants typically show a reduction in surface wear and scratches by up to 70%, extending product lifespan in high-contact applications. Enhanced wear resistance makes abrasion resistant polycarbonate ideal for use in protective eyewear, automotive glazing, and electronic device screens where maintaining clarity and integrity is critical.

Optical Clarity and Light Transmission Differences

Abrasion resistant polycarbonate exhibits enhanced surface durability without compromising optical clarity, maintaining high light transmission rates comparable to standard polycarbonate. The specialized hard coating on abrasion resistant polycarbonate minimizes micro-scratches, which can otherwise scatter light and reduce transparency. Standard polycarbonate offers excellent light transmission around 88-92%, while abrasion resistant variants sustain similar levels, ensuring clear visibility in demanding environments.

Scratch Resistance Performance Evaluation

Abrasion resistant polycarbonate exhibits significantly higher scratch resistance compared to standard polycarbonate, making it ideal for applications requiring durability against surface wear. Laboratory evaluations show that scratch depth and visibility are reduced by up to 70% with abrasion resistant variants. This enhanced performance extends the lifespan and clarity of polycarbonate products used in eyewear, automotive parts, and protective equipment.

Common Uses of Standard Polycarbonate

Standard polycarbonate is widely used in applications requiring strong, lightweight, and impact-resistant materials such as eyewear lenses, automotive components, and electronic housings. Its excellent optical clarity and heat resistance make it ideal for manufacturing safety goggles, transparent roofing, and protective barriers. Standard polycarbonate also finds extensive use in consumer products like water bottles, CDs, and greenhouses where durability and transparency are essential.

Specialized Applications for Abrasion Resistant Polycarbonate

Abrasion resistant polycarbonate is engineered with enhanced surface coatings or additives, making it ideal for specialized applications such as protective eyewear, automotive headlamp lenses, and industrial machine guards where surface durability is critical. This variant resists scratching, extending product lifespan and maintaining optical clarity under harsh conditions. Standard polycarbonate, while impact-resistant, lacks the same level of surface hardness, limiting its suitability for environments with frequent abrasive contact.

Choosing the Right Polycarbonate for Your Project

Abrasion resistant polycarbonate offers enhanced surface durability, making it ideal for high-traffic or impact-prone environments compared to standard polycarbonate which is more susceptible to scratches. Selecting the right polycarbonate depends on project requirements such as exposure to harsh conditions, longevity needs, and optical clarity. Prioritizing abrasion resistance ensures extended product lifespan and maintained aesthetics in demanding applications.

Abrasion Resistant Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com