Film extrusion produces thin, flexible plastic films primarily used for packaging and wrapping applications, offering high clarity and elasticity. Sheet extrusion creates thicker, rigid plastic sheets ideal for thermoforming, automotive parts, and signage, providing superior strength and uniform thickness. Both processes utilize similar extrusion techniques but differ in die design and cooling methods to achieve their specific product characteristics.

Table of Comparison

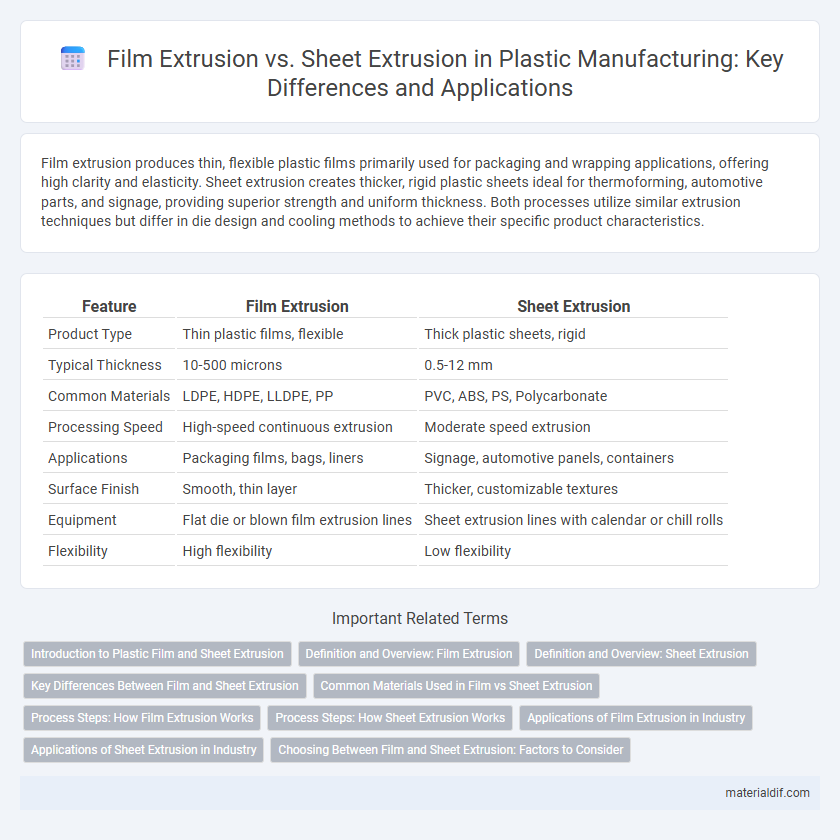

| Feature | Film Extrusion | Sheet Extrusion |

|---|---|---|

| Product Type | Thin plastic films, flexible | Thick plastic sheets, rigid |

| Typical Thickness | 10-500 microns | 0.5-12 mm |

| Common Materials | LDPE, HDPE, LLDPE, PP | PVC, ABS, PS, Polycarbonate |

| Processing Speed | High-speed continuous extrusion | Moderate speed extrusion |

| Applications | Packaging films, bags, liners | Signage, automotive panels, containers |

| Surface Finish | Smooth, thin layer | Thicker, customizable textures |

| Equipment | Flat die or blown film extrusion lines | Sheet extrusion lines with calendar or chill rolls |

| Flexibility | High flexibility | Low flexibility |

Introduction to Plastic Film and Sheet Extrusion

Plastic film extrusion involves producing thin, flexible sheets used in packaging, agriculture, and labeling by melting polymer resins and forming them into continuous films through slot die or blown film processes. Sheet extrusion produces thicker, rigid or semi-rigid sheets for applications like signage, automotive parts, and thermoforming by forcing melted plastic through flat dies and cooling it on rolls. Both methods rely on precise temperature control and extrusion speed to ensure consistent thickness, mechanical properties, and surface finish of the final plastic product.

Definition and Overview: Film Extrusion

Film extrusion, a plastic manufacturing process, transforms molten polymer into thin, flexible plastic films used for packaging, agriculture, and medical applications. This technique typically involves blowing or casting, where the polymer is extruded through a circular die to create a tubular film or through a flat die for a flat film, achieving precise thickness and width control. Film extrusion enables high-speed production of lightweight, transparent, and durable films tailored for barrier protection and printability.

Definition and Overview: Sheet Extrusion

Sheet extrusion is a plastic manufacturing process where molten polymer is forced through a flat die to create continuous, thin, flat plastic sheets. This method produces uniform sheets used in packaging, thermoforming, and industrial applications. The process allows precise control over thickness and surface finish, differentiating it from film extrusion, which typically produces thinner, flexible films through a tubular or slot die.

Key Differences Between Film and Sheet Extrusion

Film extrusion produces thin, flexible plastic films typically used for packaging, while sheet extrusion creates thicker, rigid plastic sheets for applications like signage and automotive parts. Key differences include film extrusion using blown or cast processes to achieve uniform thickness and clarity, whereas sheet extrusion employs flat die systems for thicker, dimensionally stable products. The material properties, processing temperatures, and equipment configurations vary to optimize for the distinct end-use requirements of films versus sheets.

Common Materials Used in Film vs Sheet Extrusion

Film extrusion commonly utilizes low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and polypropylene (PP) due to their flexibility and clarity, ideal for packaging applications. Sheet extrusion typically involves high-density polyethylene (HDPE), polystyrene (PS), and polycarbonate (PC), chosen for their rigidity and impact resistance required in automotive, construction, and consumer products. These material distinctions influence mechanical properties, with film materials prioritizing elongation and toughness, while sheet materials emphasize stiffness and dimensional stability.

Process Steps: How Film Extrusion Works

Film extrusion involves melting plastic pellets and forcing the molten polymer through a flat or circular die to form a thin film. The continuous film is then rapidly cooled, stretched, and solidified to achieve the desired thickness and mechanical properties. This process differs from sheet extrusion by producing much thinner and more flexible materials typically used for packaging and protective wraps.

Process Steps: How Sheet Extrusion Works

Sheet extrusion involves melting plastic pellets and forcing the molten polymer through a flat die to form a continuous sheet. The extruded sheet passes through a series of cooling rolls that solidify and calibrate its thickness and surface finish. Precise control of temperature, screw speed, and cooling rate is essential to ensure uniform sheet quality and desired mechanical properties.

Applications of Film Extrusion in Industry

Film extrusion is widely used in packaging industries due to its ability to produce thin, flexible plastic films ideal for wrapping, sealing, and laminating products. Applications extend to agricultural films for crop protection, medical packaging for sterile environments, and consumer goods such as shopping bags and protective covers. This process supports high-speed production and precise thickness control, making it essential for industries requiring lightweight, durable, and transparent materials.

Applications of Sheet Extrusion in Industry

Sheet extrusion is widely used in industries such as packaging, automotive, and construction due to its ability to produce flat, uniform plastic sheets ideal for thermoforming, laminating, and fabricating. Common applications include protective panels, food containers, automotive interior parts, and signage, where precise thickness and surface finish are critical. The versatility of materials like ABS, polycarbonate, and polypropylene in sheet extrusion enables the creation of durable, lightweight, and customizable products essential for industrial manufacturing.

Choosing Between Film and Sheet Extrusion: Factors to Consider

Choosing between film extrusion and sheet extrusion depends on the desired product thickness and application, with film extrusion typically producing thinner, flexible materials ideal for packaging, while sheet extrusion creates thicker, rigid sheets suited for thermoforming and construction. Material type, production speed, and end-use requirements play crucial roles in determining the appropriate extrusion method to optimize cost-efficiency and product performance. Understanding the specific mechanical properties and surface finish needed can guide manufacturers in selecting the most suitable extrusion process for their plastic components.

Film Extrusion vs Sheet Extrusion Infographic

materialdif.com

materialdif.com