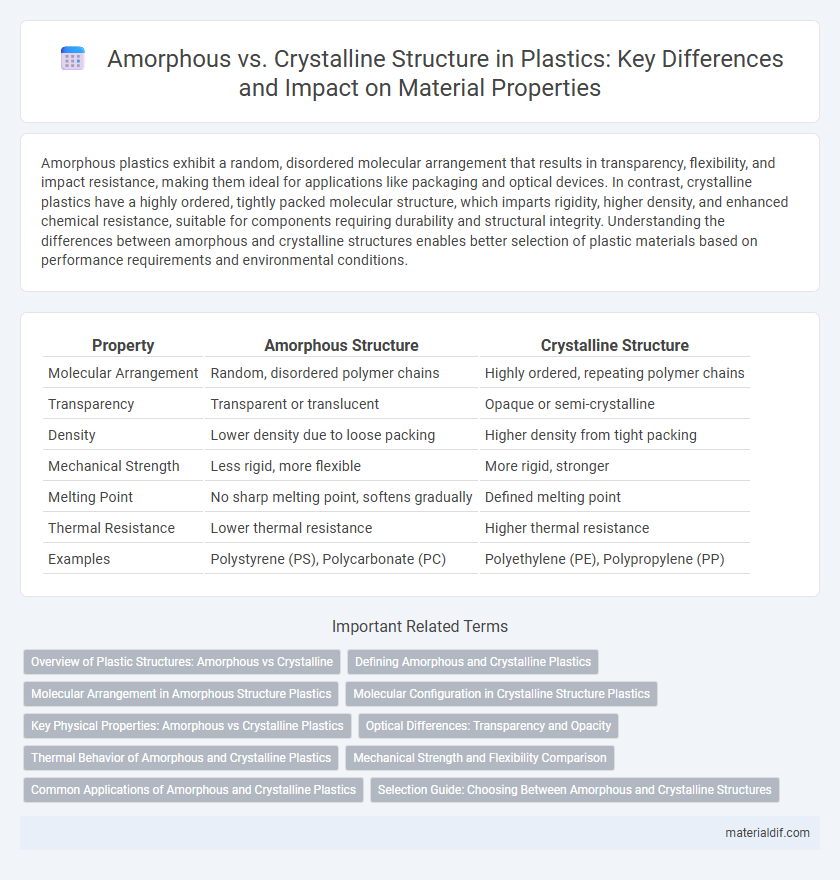

Amorphous plastics exhibit a random, disordered molecular arrangement that results in transparency, flexibility, and impact resistance, making them ideal for applications like packaging and optical devices. In contrast, crystalline plastics have a highly ordered, tightly packed molecular structure, which imparts rigidity, higher density, and enhanced chemical resistance, suitable for components requiring durability and structural integrity. Understanding the differences between amorphous and crystalline structures enables better selection of plastic materials based on performance requirements and environmental conditions.

Table of Comparison

| Property | Amorphous Structure | Crystalline Structure |

|---|---|---|

| Molecular Arrangement | Random, disordered polymer chains | Highly ordered, repeating polymer chains |

| Transparency | Transparent or translucent | Opaque or semi-crystalline |

| Density | Lower density due to loose packing | Higher density from tight packing |

| Mechanical Strength | Less rigid, more flexible | More rigid, stronger |

| Melting Point | No sharp melting point, softens gradually | Defined melting point |

| Thermal Resistance | Lower thermal resistance | Higher thermal resistance |

| Examples | Polystyrene (PS), Polycarbonate (PC) | Polyethylene (PE), Polypropylene (PP) |

Overview of Plastic Structures: Amorphous vs Crystalline

Plastic materials exhibit two primary structural forms: amorphous and crystalline. Amorphous plastics lack a defined molecular order, resulting in transparency and impact resistance, while crystalline plastics possess tightly packed molecular chains that enhance strength, chemical resistance, and thermal stability. The degree of crystallinity in plastics such as polyethylene and polypropylene directly influences mechanical properties, processing techniques, and final application performance.

Defining Amorphous and Crystalline Plastics

Amorphous plastics consist of polymer chains arranged in a random, disordered manner, resulting in materials like polycarbonate and polystyrene that exhibit transparency and impact resistance. Crystalline plastics feature highly ordered, tightly packed polymer chains as seen in polyethylene and polypropylene, which contribute to higher density, melting points, and mechanical strength. The degree of crystallinity directly affects physical properties such as stiffness, clarity, and chemical resistance in plastic materials.

Molecular Arrangement in Amorphous Structure Plastics

Amorphous structure plastics exhibit a random, disordered molecular arrangement without a defined geometric pattern, resulting in isotropic mechanical properties and increased transparency. The molecular chains in these materials are entangled but lack the long-range order found in crystalline structures, leading to lower density and reduced melting points. This irregular arrangement enhances flexibility and impact resistance compared to crystalline plastics, which have tightly packed, highly ordered molecules.

Molecular Configuration in Crystalline Structure Plastics

Crystalline structure plastics exhibit a highly ordered molecular configuration where polymer chains are tightly packed in a regular, repeating pattern, enhancing mechanical strength and thermal resistance. This molecular arrangement results in distinct melting points and improved density compared to amorphous plastics, which have randomly coiled chains. The precise alignment of molecules in crystalline plastics enables superior rigidity, chemical resistance, and dimensional stability essential for engineering applications.

Key Physical Properties: Amorphous vs Crystalline Plastics

Amorphous plastics exhibit a random, disordered molecular arrangement, resulting in lower density, increased impact resistance, and enhanced optical clarity compared to crystalline plastics. Crystalline plastics possess highly ordered molecular structures, leading to higher melting points, greater tensile strength, and improved chemical resistance. The degree of crystallinity directly influences thermal behavior, mechanical performance, and transparency in polymer materials.

Optical Differences: Transparency and Opacity

Amorphous plastics exhibit higher transparency due to their random molecular arrangement, which minimizes light scattering and allows more light to pass through. Crystalline plastics have ordered molecular structures that create boundaries and scattering centers, resulting in opacity or translucency. The degree of crystallinity directly influences optical properties, with increased crystallinity generally reducing transparency in plastic materials.

Thermal Behavior of Amorphous and Crystalline Plastics

Amorphous plastics exhibit a gradual softening over a broad temperature range due to their disordered molecular arrangement, resulting in a glass transition temperature (Tg) rather than a sharp melting point. Crystalline plastics display distinct melting temperatures (Tm) with abrupt phase changes caused by their highly ordered polymer chains, leading to greater thermal stability and higher heat resistance. The thermal behavior differences between amorphous and crystalline plastics critically impact applications requiring specific heat tolerance and mechanical performance under temperature variations.

Mechanical Strength and Flexibility Comparison

Amorphous plastic structures exhibit higher flexibility due to their random molecular arrangement, allowing greater molecular mobility under stress. In contrast, crystalline plastics have a highly ordered molecular structure that enhances mechanical strength and rigidity but reduces flexibility. The degree of crystallinity directly affects tensile strength and impact resistance, with crystalline regions providing improved durability while amorphous regions contribute to elasticity.

Common Applications of Amorphous and Crystalline Plastics

Amorphous plastics, characterized by their disordered molecular chains, are commonly used in applications requiring transparency and impact resistance, such as optical lenses, automotive headlight covers, and medical devices. Crystalline plastics, featuring highly ordered polymer chains, excel in applications demanding high strength, chemical resistance, and thermal stability, including packaging films, automotive parts, and electrical components. The distinct molecular arrangements dictate the mechanical and thermal properties, guiding their selection for specialized industrial and consumer products.

Selection Guide: Choosing Between Amorphous and Crystalline Structures

Amorphous plastics offer superior impact resistance and better optical clarity due to their random molecular arrangement, making them ideal for applications requiring transparency and flexibility. Crystalline plastics provide higher chemical resistance, dimensional stability, and mechanical strength because of their ordered molecular structure, suitable for load-bearing and high-temperature environments. Selecting between amorphous and crystalline plastics depends on balancing performance requirements such as toughness, clarity, thermal resistance, and environmental exposure.

Amorphous Structure vs Crystalline Structure Infographic

materialdif.com

materialdif.com