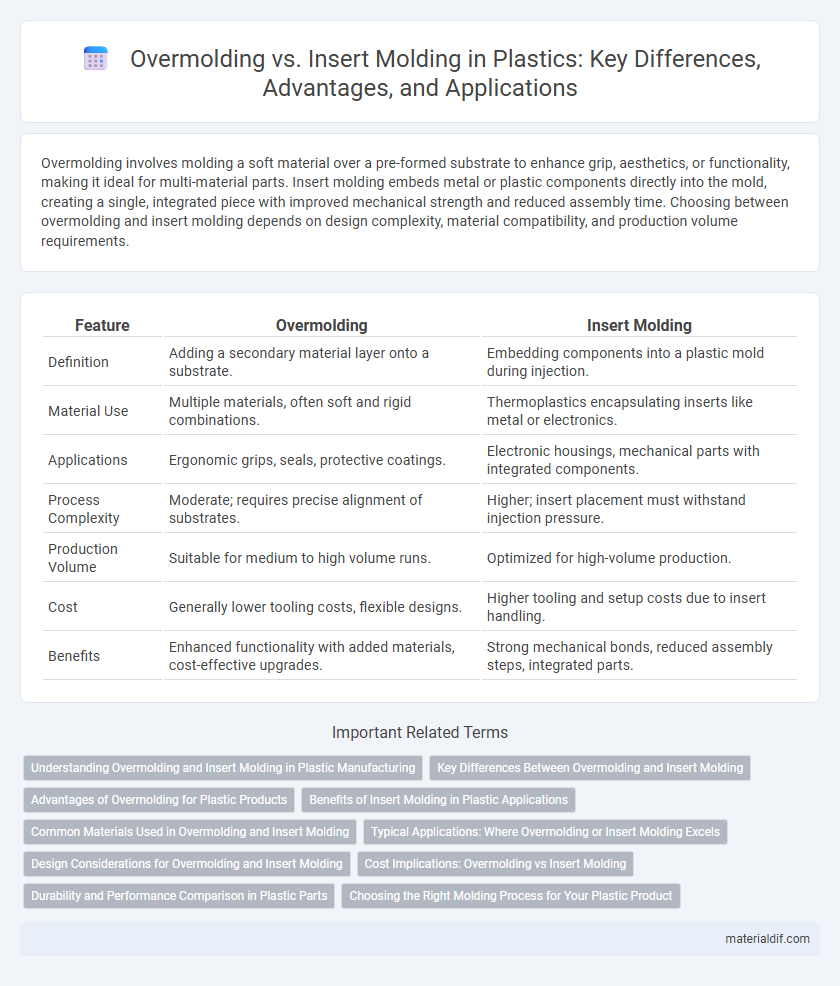

Overmolding involves molding a soft material over a pre-formed substrate to enhance grip, aesthetics, or functionality, making it ideal for multi-material parts. Insert molding embeds metal or plastic components directly into the mold, creating a single, integrated piece with improved mechanical strength and reduced assembly time. Choosing between overmolding and insert molding depends on design complexity, material compatibility, and production volume requirements.

Table of Comparison

| Feature | Overmolding | Insert Molding |

|---|---|---|

| Definition | Adding a secondary material layer onto a substrate. | Embedding components into a plastic mold during injection. |

| Material Use | Multiple materials, often soft and rigid combinations. | Thermoplastics encapsulating inserts like metal or electronics. |

| Applications | Ergonomic grips, seals, protective coatings. | Electronic housings, mechanical parts with integrated components. |

| Process Complexity | Moderate; requires precise alignment of substrates. | Higher; insert placement must withstand injection pressure. |

| Production Volume | Suitable for medium to high volume runs. | Optimized for high-volume production. |

| Cost | Generally lower tooling costs, flexible designs. | Higher tooling and setup costs due to insert handling. |

| Benefits | Enhanced functionality with added materials, cost-effective upgrades. | Strong mechanical bonds, reduced assembly steps, integrated parts. |

Understanding Overmolding and Insert Molding in Plastic Manufacturing

Overmolding involves molding a soft or flexible material over a hardened substrate, creating a multi-material component with enhanced functionality and aesthetics, commonly used in medical devices and electronics. Insert molding embeds pre-formed components or inserts into a mold before injecting plastic, ensuring mechanical bonding and reducing assembly steps, often applied in automotive and consumer goods industries. Both techniques improve product durability and design complexity but differ in process integration and material interaction.

Key Differences Between Overmolding and Insert Molding

Overmolding involves molding a soft or flexible material over a rigid substrate, typically enhancing grip or aesthetics, while insert molding integrates rigid components, such as metal or plastic inserts, directly into the molded part for structural reinforcement. Insert molding requires precise placement of inserts within the mold, whereas overmolding often uses multi-shot molding processes to layer materials. The key differences lie in application focus, with overmolding enhancing surface properties and insert molding providing embedded strength and functionality.

Advantages of Overmolding for Plastic Products

Overmolding enhances plastic product versatility by enabling the combination of multiple materials into a single, robust component, improving durability and tactile feel. It allows for complex designs with varied textures and colors without additional assembly, reducing labor costs and production time. Overmolding also provides excellent insulation properties, making it ideal for ergonomic grips and protective casings in electronics and automotive applications.

Benefits of Insert Molding in Plastic Applications

Insert molding offers enhanced mechanical strength by securely encapsulating metal or plastic components within a molded plastic part, reducing assembly steps and improving product durability. This process provides superior design flexibility and tighter tolerances, enabling seamless integration of inserts that enhance electrical conductivity, thermal management, or structural reinforcement. Insert molding also minimizes post-molding operations, lowers labor costs, and ensures consistent quality in complex plastic assemblies.

Common Materials Used in Overmolding and Insert Molding

Common materials used in overmolding include thermoplastics such as polypropylene, thermoplastic elastomers (TPE), and polycarbonate, chosen for their flexibility and strong adhesion properties. Insert molding typically involves materials like nylon, polycarbonate, and metal inserts combined with thermoplastics, offering high strength and durability. Both processes require careful material compatibility considerations to ensure optimal bonding and performance in the final product.

Typical Applications: Where Overmolding or Insert Molding Excels

Overmolding excels in producing ergonomic grips, multi-material consumer products, and wearable devices by combining flexible and rigid materials for enhanced comfort and functionality. Insert molding is ideal for embedding metal components into plastic parts, commonly used in automotive assemblies, electronic housings, and medical devices requiring strong mechanical bonds and precise placement. Both techniques enable complex part designs but differ in application focus--overmolding emphasizes material integration and tactile properties, while insert molding prioritizes component reinforcement and assembly consolidation.

Design Considerations for Overmolding and Insert Molding

Overmolding design requires careful selection of compatible materials to ensure proper adhesion and flexibility between the base substrate and the overmolded layer, while maintaining dimensional tolerances and avoiding stress concentrations. Insert molding demands precise placement and secure encapsulation of metal or plastic inserts within the mold cavity, focusing on insert stability, thermal expansion compatibility, and preventing displacement during injection. Both techniques necessitate thorough evaluation of part geometry, material properties, and processing parameters to achieve optimal bonding strength and functional performance.

Cost Implications: Overmolding vs Insert Molding

Overmolding typically incurs higher initial tooling costs than insert molding due to the complexity of producing multi-material molds. Insert molding lowers labor expenses by automating the integration of preformed components during the molding process, which reduces assembly steps. Considering long-term production, overmolding offers savings by minimizing secondary operations, whereas insert molding is more cost-effective for low to medium volume runs with less intricate designs.

Durability and Performance Comparison in Plastic Parts

Overmolding offers enhanced durability by providing a strong bond between different materials, improving resistance to impact and environmental factors in plastic parts. Insert molding embeds metal or other components within the plastic, resulting in superior mechanical strength and stability under heavy loads. Performance comparisons highlight overmolding for flexible design applications, while insert molding excels in load-bearing and precision-required components.

Choosing the Right Molding Process for Your Plastic Product

Overmolding offers versatility by allowing multiple materials or colors to be combined in a single product, ideal for ergonomic designs and enhancing grip on plastic parts. Insert molding embeds metal or other components directly into the plastic during molding, providing increased durability and reducing assembly steps in precision applications. Selecting between overmolding and insert molding depends on product requirements such as complexity, material compatibility, and cost-efficiency for manufacturing plastic components.

Overmolding vs Insert Molding Infographic

materialdif.com

materialdif.com