Polycarbonate offers superior impact resistance and greater durability compared to acrylic, making it ideal for applications requiring toughness and safety. Acrylic, on the other hand, provides better optical clarity and scratch resistance, often preferred for displays and lenses. Both materials are lightweight and weather-resistant, but selection depends on whether strength or visual quality is the priority.

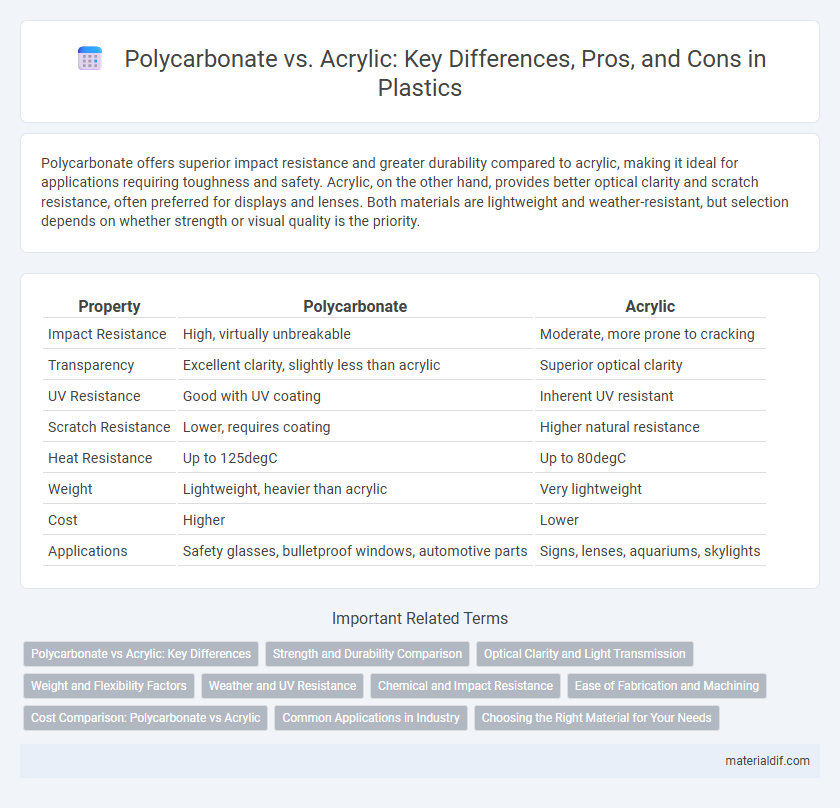

Table of Comparison

| Property | Polycarbonate | Acrylic |

|---|---|---|

| Impact Resistance | High, virtually unbreakable | Moderate, more prone to cracking |

| Transparency | Excellent clarity, slightly less than acrylic | Superior optical clarity |

| UV Resistance | Good with UV coating | Inherent UV resistant |

| Scratch Resistance | Lower, requires coating | Higher natural resistance |

| Heat Resistance | Up to 125degC | Up to 80degC |

| Weight | Lightweight, heavier than acrylic | Very lightweight |

| Cost | Higher | Lower |

| Applications | Safety glasses, bulletproof windows, automotive parts | Signs, lenses, aquariums, skylights |

Polycarbonate vs Acrylic: Key Differences

Polycarbonate offers superior impact resistance and higher heat tolerance compared to acrylic, making it ideal for safety applications and environments with extreme temperatures. Acrylic provides better optical clarity and is more resistant to UV light, resulting in less yellowing over time. Cost-wise, acrylic is generally more affordable than polycarbonate, but polycarbonate's durability often justifies the higher price in demanding uses.

Strength and Durability Comparison

Polycarbonate exhibits superior impact resistance and toughness compared to acrylic, making it the preferred choice for applications requiring high strength and durability. Acrylic offers better scratch resistance and maintains clarity over time but is more prone to cracking under stress. The enhanced resilience of polycarbonate ensures longer lifespan in demanding environments, while acrylic suits aesthetic uses with moderate strength needs.

Optical Clarity and Light Transmission

Polycarbonate offers higher impact resistance but typically has slightly lower optical clarity compared to acrylic, which provides superior transparency and light transmission rates of up to 92%. Acrylic sheets are often preferred in applications requiring excellent visual performance due to their minimal light distortion and high refractive index. Both materials allow substantial light passage, but acrylic's optical properties make it the optimal choice for displays and glazing where clarity is paramount.

Weight and Flexibility Factors

Polycarbonate offers superior flexibility compared to acrylic, making it less prone to cracking under stress or impact. It is also generally heavier than acrylic, which is known for being lightweight and rigid. These weight and flexibility differences influence the choice between polycarbonate and acrylic in applications requiring durability and ease of handling.

Weather and UV Resistance

Polycarbonate offers superior weather and UV resistance compared to acrylic, maintaining clarity and strength even under prolonged sun exposure and harsh environmental conditions. Acrylic tends to yellow and degrade faster when exposed to UV rays, making it less suitable for outdoor applications requiring long-term durability. Polycarbonate's UV-resistant coatings enhance its lifespan, providing reliable performance in roofing, glazing, and outdoor signage.

Chemical and Impact Resistance

Polycarbonate exhibits superior impact resistance compared to acrylic, making it ideal for applications requiring durability and high impact tolerance. Chemically, polycarbonate resists alkalis and alcohols but is vulnerable to solvents like acetone, whereas acrylic offers greater resistance to UV exposure and many chemicals but is more brittle under impact. Selecting between polycarbonate and acrylic depends on balancing the need for chemical resistance with the requirement for mechanical strength in specific environmental conditions.

Ease of Fabrication and Machining

Polycarbonate offers superior ease of fabrication and machining due to its high impact resistance and better thermal stability, allowing for cutting, drilling, and forming without cracking. Acrylic, while providing excellent optical clarity, is more brittle and prone to chipping or cracking during machining processes, requiring more careful handling and specialized tools. Choosing polycarbonate reduces fabrication time and lowers the risk of material failure, making it ideal for applications demanding durability and precision.

Cost Comparison: Polycarbonate vs Acrylic

Polycarbonate typically costs more than acrylic due to its higher impact resistance and durability, making it suitable for demanding applications. Acrylic offers a budget-friendly alternative with excellent clarity but lower strength, ideal for decorative or light-duty purposes. When cost is a primary factor, acrylic provides significant savings, while polycarbonate justifies its higher price with superior performance and longevity.

Common Applications in Industry

Polycarbonate and acrylic are widely used plastics with distinct industrial applications due to their unique properties. Polycarbonate excels in impact-resistant applications such as automotive components, bulletproof glass, and electronic device enclosures, offering durability and high thermal resistance. Acrylic is preferred for optical clarity and aesthetic purposes, commonly found in signage, display cases, and lighting fixtures where transparency and weather resistance are critical.

Choosing the Right Material for Your Needs

Polycarbonate offers superior impact resistance and UV protection, making it ideal for outdoor applications and safety equipment, while acrylic provides better clarity and scratch resistance, suited for display cases and signage. When choosing the right material, consider factors such as durability requirements, environmental exposure, and budget constraints, as polycarbonate tends to be more expensive but longer-lasting. Evaluating the specific performance characteristics ensures optimal functionality and cost-effectiveness for your project.

Polycarbonate vs Acrylic Infographic

materialdif.com

materialdif.com