Engineering plastics offer superior mechanical strength, thermal stability, and chemical resistance compared to commodity plastics, making them ideal for high-performance applications in automotive, aerospace, and electronics industries. Commodity plastics, such as polyethylene and polypropylene, are cost-effective, easy to process, and widely used for packaging, containers, and everyday products due to their lower durability and strength. Choosing between engineering and commodity plastics depends on the balance between performance requirements and budget constraints in manufacturing processes.

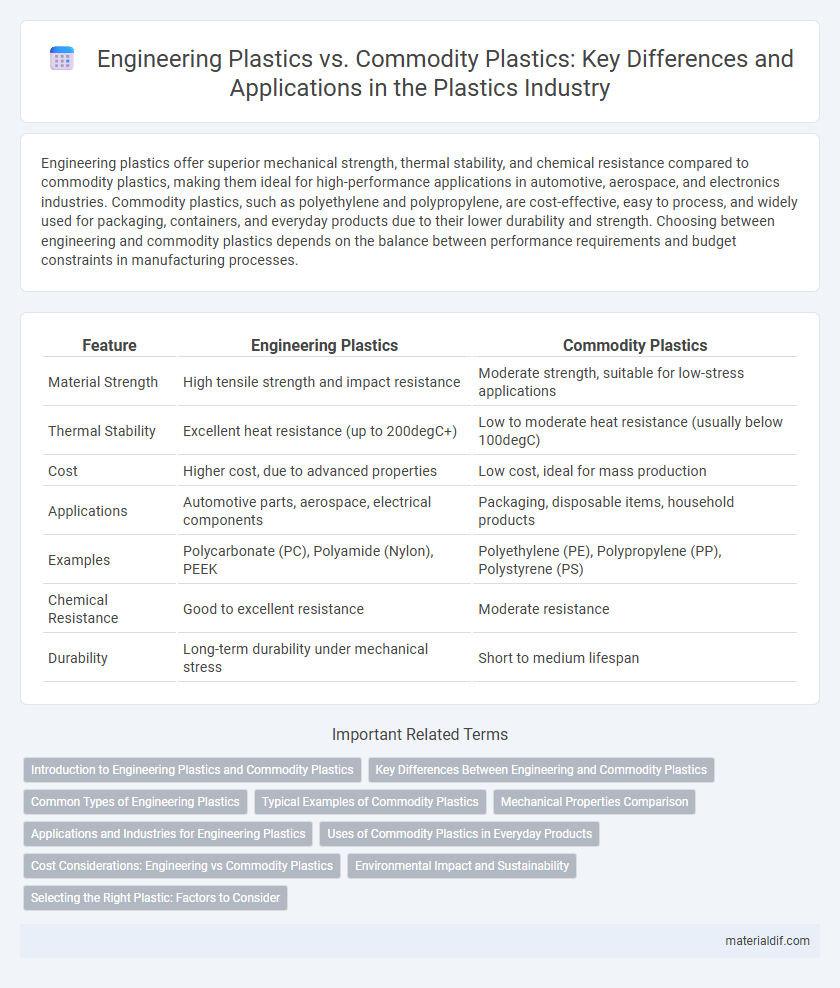

Table of Comparison

| Feature | Engineering Plastics | Commodity Plastics |

|---|---|---|

| Material Strength | High tensile strength and impact resistance | Moderate strength, suitable for low-stress applications |

| Thermal Stability | Excellent heat resistance (up to 200degC+) | Low to moderate heat resistance (usually below 100degC) |

| Cost | Higher cost, due to advanced properties | Low cost, ideal for mass production |

| Applications | Automotive parts, aerospace, electrical components | Packaging, disposable items, household products |

| Examples | Polycarbonate (PC), Polyamide (Nylon), PEEK | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) |

| Chemical Resistance | Good to excellent resistance | Moderate resistance |

| Durability | Long-term durability under mechanical stress | Short to medium lifespan |

Introduction to Engineering Plastics and Commodity Plastics

Engineering plastics are a category of plastic materials known for their superior mechanical and thermal properties, making them suitable for high-performance applications in automotive, aerospace, and electronics industries. Commodity plastics, such as polyethylene (PE), polypropylene (PP), and polystyrene (PS), are produced in large volumes primarily for everyday products due to their cost-effectiveness and ease of processing. The key distinction lies in engineering plastics' enhanced durability, chemical resistance, and higher melting points compared to commodity plastics, which are typically used in packaging, containers, and household items.

Key Differences Between Engineering and Commodity Plastics

Engineering plastics exhibit superior mechanical properties, higher heat resistance, and enhanced chemical stability compared to commodity plastics, making them suitable for demanding applications in automotive, aerospace, and electronics industries. Commodity plastics like polyethylene, polypropylene, and polystyrene are cost-effective and widely used for packaging, containers, and consumer goods due to their ease of processing and lower performance requirements. The primary differences lie in the materials' performance characteristics, cost, and intended application environments, with engineering plastics offering advanced durability and strength.

Common Types of Engineering Plastics

Common types of engineering plastics include polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (nylon), and polyoxymethylene (POM). These materials offer superior mechanical strength, thermal resistance, and chemical stability compared to commodity plastics like polyethylene (PE) and polypropylene (PP). Engineering plastics are widely used in automotive, aerospace, and electrical applications due to their enhanced performance characteristics and durability.

Typical Examples of Commodity Plastics

Typical examples of commodity plastics include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polystyrene (PS), widely used in packaging, containers, and disposable products. These plastics offer cost-effective solutions with moderate mechanical properties and ease of processing suitable for mass production. Their lower thermal resistance and strength compared to engineering plastics limit their use in high-performance applications.

Mechanical Properties Comparison

Engineering plastics exhibit superior mechanical properties compared to commodity plastics, including higher tensile strength, enhanced impact resistance, and greater dimensional stability under stress. Common engineering plastics such as polycarbonate, polyamide (nylon), and PEEK offer exceptional durability in demanding applications, outperforming commodity plastics like polyethylene and polypropylene, which are typically used in low-stress environments. The reinforced mechanical performance of engineering plastics makes them ideal for automotive, aerospace, and industrial components requiring reliability and longevity.

Applications and Industries for Engineering Plastics

Engineering plastics are extensively used in automotive, aerospace, and electronics industries due to their superior mechanical strength, thermal stability, and chemical resistance compared to commodity plastics. Applications include precision parts, electrical insulation components, and structural elements subjected to high stress and temperature. These materials enable manufacturing of durable, high-performance products in sectors demanding long-term reliability and advanced engineering properties.

Uses of Commodity Plastics in Everyday Products

Commodity plastics, such as polyethylene (PE), polypropylene (PP), and polystyrene (PS), dominate everyday products due to their low cost and versatility. They are commonly used in packaging materials, disposable containers, and household items like bottles, bags, and food wrap. These plastics provide essential durability and lightweight properties, making them ideal for mass-produced consumer goods.

Cost Considerations: Engineering vs Commodity Plastics

Engineering plastics, such as polycarbonate and nylon, incur higher initial costs due to superior mechanical properties and thermal resistance, justifying their use in high-performance applications. Commodity plastics like polyethylene and polypropylene are cost-effective options favored for mass production with moderate durability and flexibility. Cost considerations balance material performance requirements against budget constraints, influencing the choice between engineering and commodity plastics in manufacturing processes.

Environmental Impact and Sustainability

Engineering plastics offer enhanced durability and longer lifecycle compared to commodity plastics, reducing the frequency of replacement and waste generation. Their higher performance often enables lightweight designs, leading to energy savings during product use and transportation. Although production of engineering plastics can involve higher energy consumption, their extended usability and recyclability contribute to improved overall environmental sustainability.

Selecting the Right Plastic: Factors to Consider

Selecting the right plastic involves evaluating mechanical strength, chemical resistance, and thermal stability, which typically favor engineering plastics like polycarbonate and nylon over commodity plastics such as polyethylene or polypropylene. Cost efficiency and ease of fabrication often position commodity plastics as suitable for less demanding applications, while engineering plastics provide superior performance in high-stress environments. Consideration of environmental impact, recyclability, and end-use requirements also guides the decision between these two categories.

Engineering Plastics vs Commodity Plastics Infographic

materialdif.com

materialdif.com