Plastic PET exhibits noticeable thermal expansion when exposed to increasing temperatures, which can affect its dimensional accuracy in precise applications. However, its excellent thermal stability allows it to maintain structural integrity and resist degradation over a broad temperature range. This balance between thermal expansion and stability makes PET suitable for packaging, where durability and shape retention under varying thermal conditions are critical.

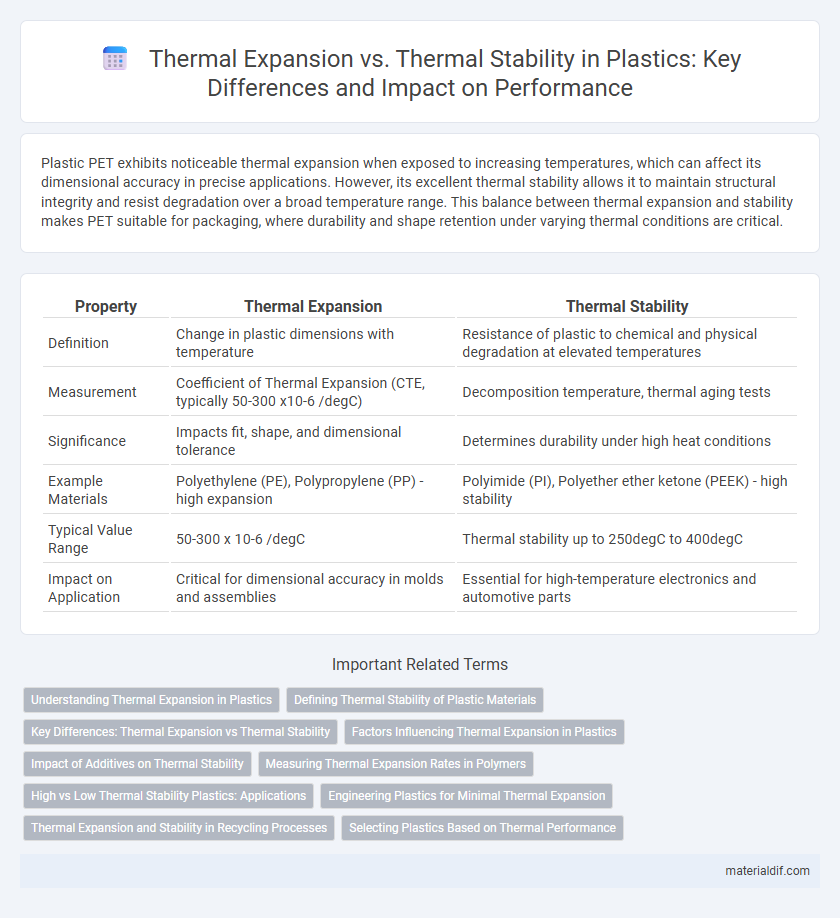

Table of Comparison

| Property | Thermal Expansion | Thermal Stability |

|---|---|---|

| Definition | Change in plastic dimensions with temperature | Resistance of plastic to chemical and physical degradation at elevated temperatures |

| Measurement | Coefficient of Thermal Expansion (CTE, typically 50-300 x10-6 /degC) | Decomposition temperature, thermal aging tests |

| Significance | Impacts fit, shape, and dimensional tolerance | Determines durability under high heat conditions |

| Example Materials | Polyethylene (PE), Polypropylene (PP) - high expansion | Polyimide (PI), Polyether ether ketone (PEEK) - high stability |

| Typical Value Range | 50-300 x 10-6 /degC | Thermal stability up to 250degC to 400degC |

| Impact on Application | Critical for dimensional accuracy in molds and assemblies | Essential for high-temperature electronics and automotive parts |

Understanding Thermal Expansion in Plastics

Thermal expansion in plastics refers to the tendency of a polymer material to increase in volume or length as temperature rises, influenced by the molecular structure and degree of crystallinity. Understanding the coefficient of thermal expansion (CTE) is crucial for designing plastic components that must withstand temperature variations without warping or mechanical failure. Unlike thermal stability, which measures a plastic's ability to resist degradation at high temperatures, thermal expansion specifically addresses dimensional changes that impact fit, assembly, and performance in applications.

Defining Thermal Stability of Plastic Materials

Thermal stability of plastic materials refers to their ability to maintain structural integrity and chemical properties when exposed to elevated temperatures over time. This property is crucial for applications requiring long-term exposure to heat without significant degradation, discoloration, or loss of mechanical strength. Unlike thermal expansion, which measures dimensional changes due to heat, thermal stability emphasizes resistance to thermal degradation and preservation of performance under thermal stress.

Key Differences: Thermal Expansion vs Thermal Stability

Thermal expansion in plastics refers to the increase in volume or dimensions when exposed to heat, quantified by the coefficient of thermal expansion (CTE), while thermal stability describes a plastic's ability to retain structural integrity and properties under high temperatures without degradation. Key differences lie in measurement and impact: thermal expansion affects physical size during heating, critical for dimensional tolerance, whereas thermal stability determines a polymer's resistance to chemical breakdown and mechanical failure at elevated temperatures. Understanding these differences guides material selection for applications requiring precise thermal management or long-term heat exposure resilience.

Factors Influencing Thermal Expansion in Plastics

Thermal expansion in plastics is primarily influenced by molecular structure, polymer chain flexibility, and filler content. Amorphous polymers typically exhibit higher thermal expansion coefficients compared to crystalline polymers due to increased free volume and chain mobility. The presence of reinforcements, such as glass fibers or mineral fillers, reduces overall thermal expansion by restricting polymer chain movement and enhancing dimensional stability.

Impact of Additives on Thermal Stability

Additives such as flame retardants, UV stabilizers, and antioxidants significantly enhance the thermal stability of plastics by preventing degradation at elevated temperatures, unlike thermal expansion which relates to the dimensional changes when heated. The inclusion of fillers, plasticizers, and nucleating agents also modifies the polymer matrix, thereby improving resistance to thermal stress and delaying the onset of thermal decomposition. These additives optimize performance in high-temperature applications by maintaining structural integrity and reducing thermal aging effects in plastic materials.

Measuring Thermal Expansion Rates in Polymers

Thermal expansion rates in polymers are measured using techniques such as thermomechanical analysis (TMA) and dynamic mechanical analysis (DMA), which quantify dimensional changes under controlled temperature variations. Coefficients of thermal expansion (CTE) are critical parameters that indicate how much a polymer expands per degree of temperature increase, influencing material selection for applications requiring dimensional stability. Accurate measurement of thermal expansion enables assessment of polymer performance in environments with fluctuating temperatures, directly impacting thermal stability and mechanical reliability.

High vs Low Thermal Stability Plastics: Applications

High thermal stability plastics such as polyimides and PEEK maintain structural integrity and performance in applications exposed to extreme temperatures, making them ideal for aerospace, automotive, and electronics components. Low thermal stability plastics like polyethylene and PVC exhibit significant thermal expansion and are suited for applications with minimal heat exposure, including packaging and household goods. Understanding the balance between thermal expansion and stability is crucial for selecting plastics that ensure durability and functionality under specific thermal conditions.

Engineering Plastics for Minimal Thermal Expansion

Engineering plastics like polyetheretherketone (PEEK) and polyphenylene sulfide (PPS) exhibit minimal thermal expansion, maintaining dimensional stability under temperature fluctuations. These materials possess high thermal stability, with glass transition temperatures often exceeding 150degC, reducing deformation risks in precision applications. Optimizing polymer crystallinity and incorporating fillers such as glass or carbon fibers further enhances thermal resistance and lowers the coefficient of thermal expansion (CTE).

Thermal Expansion and Stability in Recycling Processes

Thermal expansion in plastics significantly impacts recycling processes by causing dimensional changes that can lead to warping or distortion during remelting. Maintaining thermal stability is critical to preserve polymer integrity, as high temperatures can degrade molecular structure, reducing material performance and recyclability. Optimizing processing temperatures and selecting polymers with low thermal expansion coefficients enhance recyclability by ensuring consistent shape retention and material quality.

Selecting Plastics Based on Thermal Performance

Selecting plastics based on thermal performance requires balancing thermal expansion and thermal stability to ensure material durability under temperature fluctuations. Polymers like PTFE and HDPE exhibit high thermal expansion coefficients, making them suitable for applications tolerating dimensional changes. In contrast, materials such as PEEK and polyimide demonstrate superior thermal stability with minimal deformation at elevated temperatures, ideal for high-heat environments.

Thermal Expansion vs Thermal Stability Infographic

materialdif.com

materialdif.com