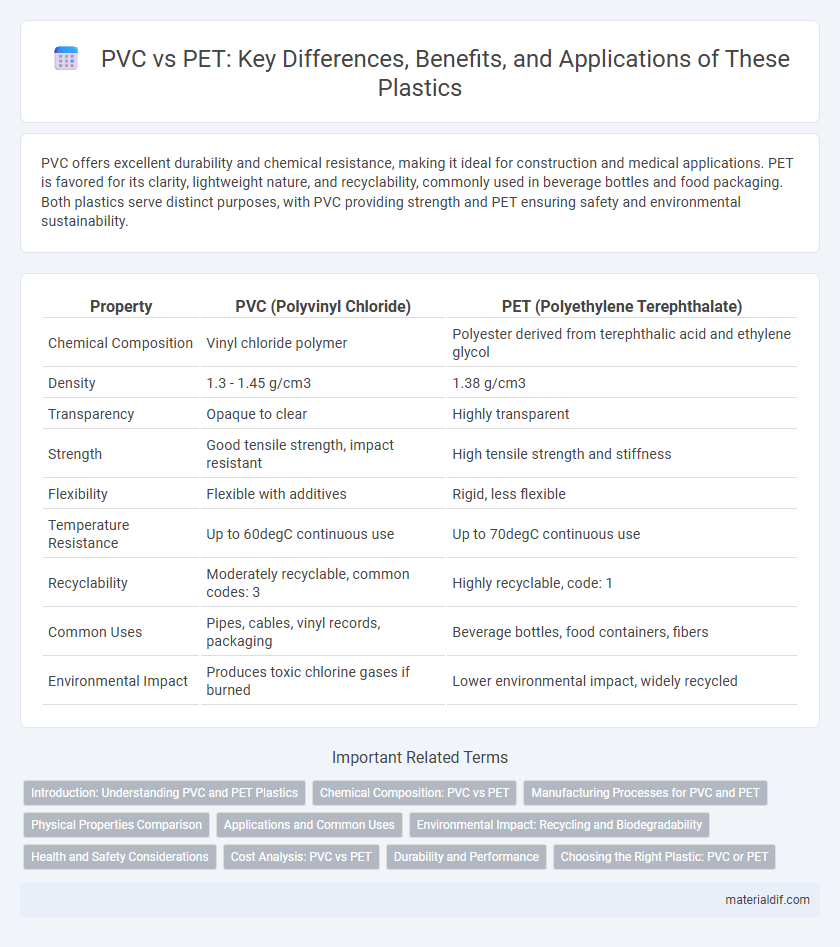

PVC offers excellent durability and chemical resistance, making it ideal for construction and medical applications. PET is favored for its clarity, lightweight nature, and recyclability, commonly used in beverage bottles and food packaging. Both plastics serve distinct purposes, with PVC providing strength and PET ensuring safety and environmental sustainability.

Table of Comparison

| Property | PVC (Polyvinyl Chloride) | PET (Polyethylene Terephthalate) |

|---|---|---|

| Chemical Composition | Vinyl chloride polymer | Polyester derived from terephthalic acid and ethylene glycol |

| Density | 1.3 - 1.45 g/cm3 | 1.38 g/cm3 |

| Transparency | Opaque to clear | Highly transparent |

| Strength | Good tensile strength, impact resistant | High tensile strength and stiffness |

| Flexibility | Flexible with additives | Rigid, less flexible |

| Temperature Resistance | Up to 60degC continuous use | Up to 70degC continuous use |

| Recyclability | Moderately recyclable, common codes: 3 | Highly recyclable, code: 1 |

| Common Uses | Pipes, cables, vinyl records, packaging | Beverage bottles, food containers, fibers |

| Environmental Impact | Produces toxic chlorine gases if burned | Lower environmental impact, widely recycled |

Introduction: Understanding PVC and PET Plastics

PVC (Polyvinyl Chloride) and PET (Polyethylene Terephthalate) are widely used plastics with distinct chemical compositions and applications. PVC is known for its rigidity, chemical resistance, and versatility in construction and piping, while PET is valued for its clarity, strength, and recyclability, making it ideal for beverage containers and packaging. Understanding their properties helps optimize material selection based on durability, environmental impact, and end-use requirements.

Chemical Composition: PVC vs PET

PVC (polyvinyl chloride) is a thermoplastic polymer made from vinyl chloride monomers, characterized by its chlorine content which provides rigidity and chemical resistance. PET (polyethylene terephthalate) is a polyester formed through the polymerization of ethylene glycol and terephthalic acid, known for its clarity, strength, and recyclability. The presence of chlorine in PVC distinguishes its chemical behavior and environmental impact from PET, which lacks halogen atoms.

Manufacturing Processes for PVC and PET

PVC manufacturing involves polymerizing vinyl chloride monomers through suspension, emulsion, or bulk polymerization methods, producing a rigid and durable plastic often enhanced with plasticizers. PET production typically uses a two-step process starting with polymerization of ethylene glycol and terephthalic acid to form a pre-polymer, followed by solid-state polymerization to achieve high molecular weight. Both plastics require precise temperature and pressure control, with PET's manufacturing emphasizing crystallinity for strength and transparency, while PVC focuses on versatility for applications like pipes and packaging.

Physical Properties Comparison

PVC (polyvinyl chloride) exhibits higher tensile strength and greater chemical resistance compared to PET (polyethylene terephthalate), making it suitable for applications requiring durability and corrosion resistance. PET offers superior clarity, impact resistance, and lighter weight, which is advantageous for packaging and beverage containers. The thermal stability of PVC allows it to withstand higher temperatures, whereas PET's crystallinity contributes to better gas barrier properties and moisture resistance.

Applications and Common Uses

PVC (polyvinyl chloride) is extensively used in construction for pipes, window frames, and electrical cable insulation due to its durability and chemical resistance. PET (polyethylene terephthalate) is primarily utilized in beverage bottles, food packaging, and synthetic fibers because of its clarity, strength, and recyclability. While PVC is favored for rigid, long-lasting applications, PET excels in lightweight, transparent packaging solutions.

Environmental Impact: Recycling and Biodegradability

PVC (polyvinyl chloride) presents significant environmental challenges due to its limited recyclability and release of harmful chemicals during degradation, contributing to long-lasting pollution. PET (polyethylene terephthalate) is more widely recycled, with established systems supporting its recovery and reuse, thereby reducing landfill waste and energy consumption. While neither plastic is truly biodegradable, PET's greater recyclability makes it a more sustainable option compared to PVC in terms of environmental impact.

Health and Safety Considerations

PVC (polyvinyl chloride) contains additives like phthalates and chlorine, which can release harmful chemicals during production, use, or disposal, raising health and environmental concerns. PET (polyethylene terephthalate) is generally considered safer for food and beverage packaging due to its chemical stability and lower risk of leaching toxins. Regulatory agencies often prefer PET for applications involving direct food contact, emphasizing its superior safety profile compared to PVC.

Cost Analysis: PVC vs PET

PVC generally offers a lower production cost compared to PET, making it a cost-effective option for applications where budget constraints are critical. PET typically incurs higher manufacturing expenses due to its more complex processing requirements and raw material prices, but it provides superior recyclability and durability. When conducting a cost analysis, evaluating lifecycle expenses and specific use-case demands is crucial to determine the most economical choice between PVC and PET.

Durability and Performance

PVC offers superior rigidity and chemical resistance, making it highly durable for long-term applications in construction and piping. PET excels in impact resistance and clarity, making it ideal for packaging and containers requiring lightweight, shatterproof materials. Both plastics demonstrate excellent thermal stability, but PET's higher tensile strength provides enhanced performance under mechanical stress.

Choosing the Right Plastic: PVC or PET

PVC (Polyvinyl Chloride) offers strong chemical resistance and durability, making it ideal for pipes, medical equipment, and construction materials, while PET (Polyethylene Terephthalate) is lightweight, transparent, and highly recyclable, commonly used in beverage bottles and food packaging. Selecting between PVC and PET depends on application requirements such as flexibility, safety standards, and environmental impact, with PET favored for food contact due to its inert nature. Cost-effectiveness and recyclability are key factors; PVC is less recyclable and may release harmful chemicals when burned, whereas PET's popularity in recycling programs supports sustainable packaging solutions.

PVC vs PET Infographic

materialdif.com

materialdif.com