Food-grade plastic is specifically designed to meet safety standards for direct contact with food and beverages, ensuring no harmful chemicals leach into consumables. Industrial-grade plastic, however, is formulated for durability and resistance in manufacturing applications, often containing additives unsuitable for food safety. Choosing the appropriate plastic type is crucial to prevent contamination and maintain product integrity.

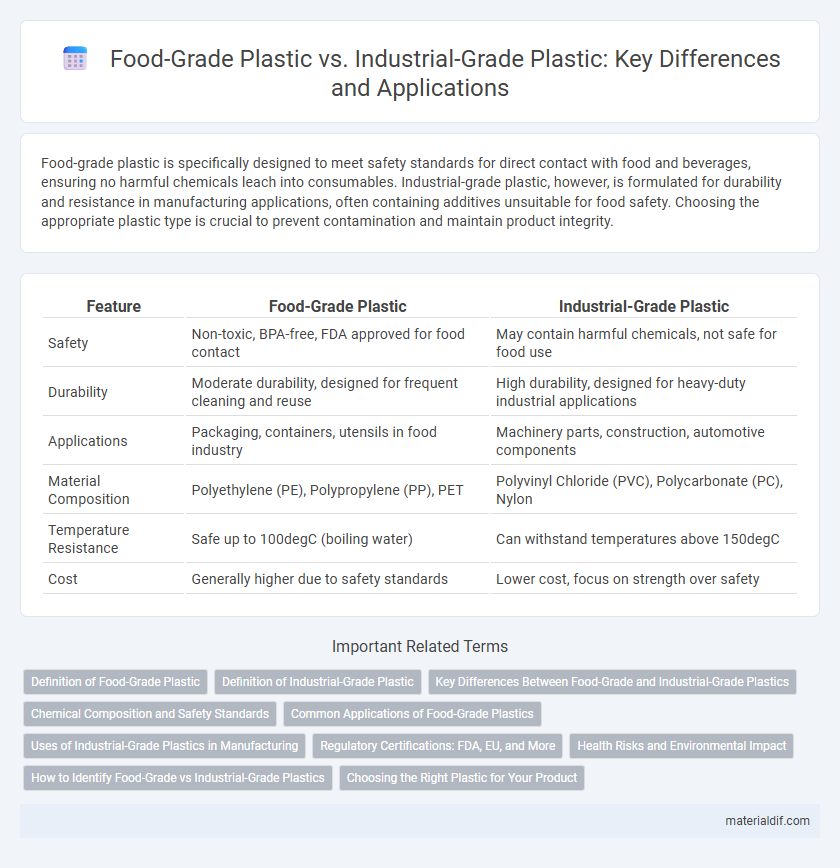

Table of Comparison

| Feature | Food-Grade Plastic | Industrial-Grade Plastic |

|---|---|---|

| Safety | Non-toxic, BPA-free, FDA approved for food contact | May contain harmful chemicals, not safe for food use |

| Durability | Moderate durability, designed for frequent cleaning and reuse | High durability, designed for heavy-duty industrial applications |

| Applications | Packaging, containers, utensils in food industry | Machinery parts, construction, automotive components |

| Material Composition | Polyethylene (PE), Polypropylene (PP), PET | Polyvinyl Chloride (PVC), Polycarbonate (PC), Nylon |

| Temperature Resistance | Safe up to 100degC (boiling water) | Can withstand temperatures above 150degC |

| Cost | Generally higher due to safety standards | Lower cost, focus on strength over safety |

Definition of Food-Grade Plastic

Food-grade plastic is specifically manufactured to meet strict safety standards set by regulatory agencies such as the FDA, ensuring it is non-toxic and free from harmful chemicals that could contaminate food. These plastics, including polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP), are designed to resist leaching and withstand temperature variations during food storage and preparation. Industrial-grade plastics, in contrast, are intended for applications without human consumption risk and may contain additives or impurities unsuitable for direct food contact.

Definition of Industrial-Grade Plastic

Industrial-grade plastic is a type of polymer material specifically designed for heavy-duty applications that require high strength, durability, and resistance to chemicals and extreme temperatures. Unlike food-grade plastic, which meets stringent safety standards for direct food contact, industrial-grade plastic is often used in manufacturing, construction, and automotive industries where toxicity and contamination risks are less critical. These plastics may contain additives that enhance physical properties but are not certified safe for food packaging or storage.

Key Differences Between Food-Grade and Industrial-Grade Plastics

Food-grade plastics are specifically engineered to comply with FDA regulations, ensuring they do not leach harmful chemicals into food or beverages, while industrial-grade plastics prioritize durability and chemical resistance for non-food applications. The molecular structure of food-grade plastic is designed to be non-toxic and resistant to contamination, making it safe for repeated use in packaging, storage, and processing of consumables. Industrial-grade plastics often incorporate additives that enhance mechanical strength and thermal stability but may release hazardous substances, disqualifying them from use in environments requiring strict hygiene and safety standards.

Chemical Composition and Safety Standards

Food-grade plastic is manufactured using non-toxic additives and resins such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP) that comply with stringent safety standards set by regulatory agencies like the FDA and EFSA to prevent chemical leaching into food. Industrial-grade plastic often contains additives like plasticizers, stabilizers, and heavy metals that enhance durability but may pose chemical risks, making them unsuitable for direct food contact. Safety standards for food-grade plastics mandate rigorous testing for migration limits and biocompatibility, ensuring consumer protection from harmful substance exposure.

Common Applications of Food-Grade Plastics

Food-grade plastics are commonly used in packaging for beverages, dairy products, and fresh produce due to their non-toxic, BPA-free, and FDA-approved properties ensuring safety and hygiene. These plastics are also prevalent in kitchenware, including containers, utensils, and cutting boards, which require resistance to contamination and easy sterilization. Their applications extend to medical devices and pharmaceutical packaging where maintaining purity and preventing chemical leaching are critical factors.

Uses of Industrial-Grade Plastics in Manufacturing

Industrial-grade plastics are extensively used in manufacturing due to their high durability, chemical resistance, and thermal stability, making them ideal for automotive parts, machinery components, and electrical insulation. These plastics enable the production of heavy-duty containers, piping systems, and structural parts that require enhanced mechanical strength and resistance to harsh environments. Unlike food-grade plastics, industrial-grade variants prioritize performance and safety in industrial applications rather than compliance with food safety standards.

Regulatory Certifications: FDA, EU, and More

Food-grade plastic complies with strict regulatory certifications such as the FDA (Food and Drug Administration) in the United States and the EU's framework regulation (EC) No 1935/2004, ensuring safety for direct food contact and preventing harmful chemical migration. Industrial-grade plastic lacks these certifications and is designed for non-food applications, often prioritizing durability over safety in ingestion scenarios. Choosing plastic with recognized certifications like FDA or EU guarantees compliance with rigorous safety standards essential for packaging, storage, and handling of consumable products.

Health Risks and Environmental Impact

Food-grade plastic is specifically designed to meet strict safety regulations, minimizing health risks by preventing the leaching of harmful chemicals into food and beverages. Industrial-grade plastic often contains additives and contaminants that pose significant health hazards if ingested and are less biodegradable, contributing to greater environmental pollution. Proper classification and use of plastic materials are crucial to reduce toxic exposure and mitigate long-term ecological damage.

How to Identify Food-Grade vs Industrial-Grade Plastics

Food-grade plastic is typically identified by specific resin identification codes such as #1 (PET), #2 (HDPE), #4 (LDPE), and #5 (PP), which meet FDA standards for food contact safety. Industrial-grade plastics often lack these certifications and may have resin codes like #3 (PVC), #6 (PS), or #7 (Other), indicating they are not intended for direct food use. Clear labeling, odor absence, and compliance with food safety regulations are key indicators to differentiate food-grade from industrial-grade plastics.

Choosing the Right Plastic for Your Product

Food-grade plastic meets strict FDA regulations ensuring safety for direct contact with consumables, making it ideal for packaging, utensils, and containers. Industrial-grade plastic offers enhanced durability and chemical resistance suited for machinery parts, automotive components, and construction materials. Selecting the right plastic depends on intended use, safety standards, and performance requirements to ensure product integrity and consumer protection.

Food-grade Plastic vs Industrial-grade Plastic Infographic

materialdif.com

materialdif.com