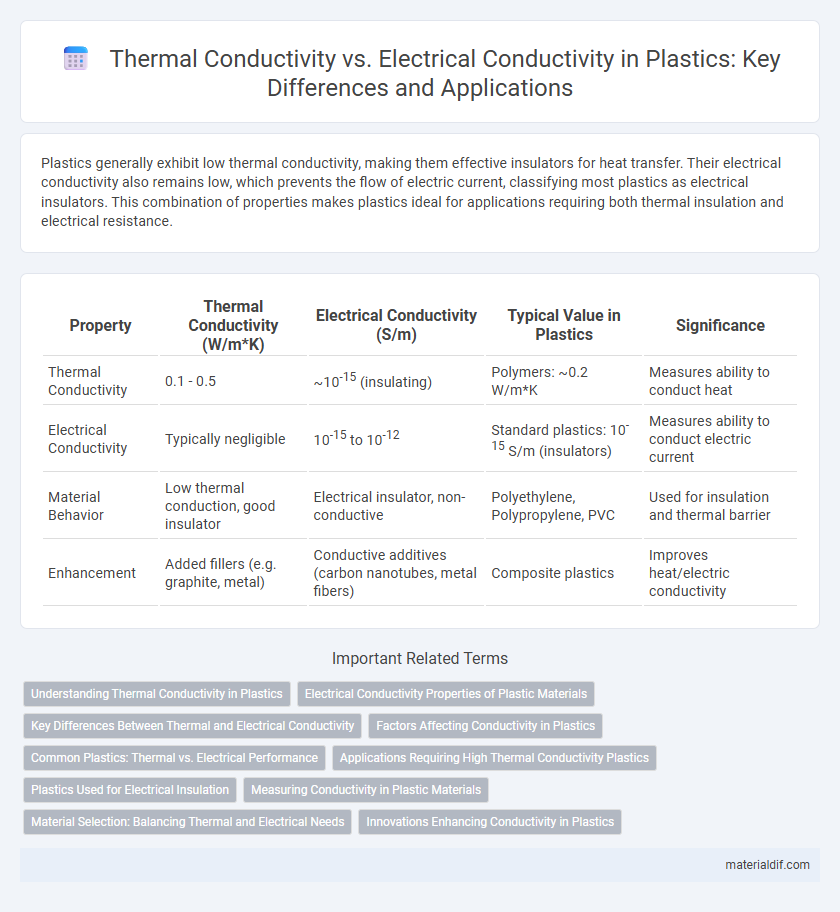

Plastics generally exhibit low thermal conductivity, making them effective insulators for heat transfer. Their electrical conductivity also remains low, which prevents the flow of electric current, classifying most plastics as electrical insulators. This combination of properties makes plastics ideal for applications requiring both thermal insulation and electrical resistance.

Table of Comparison

| Property | Thermal Conductivity (W/m*K) | Electrical Conductivity (S/m) | Typical Value in Plastics | Significance |

|---|---|---|---|---|

| Thermal Conductivity | 0.1 - 0.5 | ~10-15 (insulating) | Polymers: ~0.2 W/m*K | Measures ability to conduct heat |

| Electrical Conductivity | Typically negligible | 10-15 to 10-12 | Standard plastics: 10-15 S/m (insulators) | Measures ability to conduct electric current |

| Material Behavior | Low thermal conduction, good insulator | Electrical insulator, non-conductive | Polyethylene, Polypropylene, PVC | Used for insulation and thermal barrier |

| Enhancement | Added fillers (e.g. graphite, metal) | Conductive additives (carbon nanotubes, metal fibers) | Composite plastics | Improves heat/electric conductivity |

Understanding Thermal Conductivity in Plastics

Thermal conductivity in plastics typically ranges between 0.1 and 0.5 W/m*K, significantly lower than metals, which affects their heat dissipation capabilities in applications. Unlike electrical conductivity, which is minimal or nearly zero in most polymers due to their molecular structure, thermal conductivity depends on polymer chain alignment, crystallinity, and additives. Enhancing thermal conductivity in plastics involves incorporating fillers like carbon fibers or ceramic particles, enabling better heat transfer while maintaining electrical insulation properties.

Electrical Conductivity Properties of Plastic Materials

Plastic materials exhibit very low electrical conductivity due to their molecular structure, which lacks free electrons necessary for charge transport. Common plastics such as polyethylene, polypropylene, and polystyrene are excellent electrical insulators, with conductivity values typically below 10^-14 S/m. This characteristic makes plastics ideal for insulating electronic components and preventing electrical leakage in various industrial applications.

Key Differences Between Thermal and Electrical Conductivity

Thermal conductivity in plastics measures the material's ability to transfer heat, which is generally low due to their molecular structure and insulating properties. Electrical conductivity refers to the ability to conduct electric current and plastics typically act as excellent electrical insulators with very low conductivity values. The key difference lies in the mechanisms: thermal conductivity depends on phonon and electron movement through the polymer matrix, while electrical conductivity requires free electrons, which plastics inherently lack.

Factors Affecting Conductivity in Plastics

Thermal conductivity in plastics is influenced by factors such as molecular structure, crystallinity, and filler type, with highly crystalline polymers exhibiting enhanced heat transfer capabilities. Electrical conductivity depends largely on the polymer's intrinsic molecular architecture and the presence of conductive additives like carbon black or metal particles. Temperature, humidity, and polymer orientation further modify both thermal and electrical conductivity performance in plastic materials.

Common Plastics: Thermal vs. Electrical Performance

Common plastics such as polyethylene, polypropylene, and polystyrene exhibit low thermal conductivity ranging from 0.1 to 0.4 W/m*K, which makes them effective thermal insulators. Their electrical conductivity is typically extremely low, often below 10^-15 S/m, classifying them as excellent electrical insulators. This combination of low thermal and electrical conductivity makes common plastics ideal for applications requiring insulation from heat and electricity.

Applications Requiring High Thermal Conductivity Plastics

High thermal conductivity plastics are essential in electronics cooling applications, where efficient heat dissipation prevents component failure and extends device lifespan. Unlike traditional plastics with low electrical conductivity, these materials maintain electrical insulation while effectively transferring heat, making them ideal for LED lighting, power modules, and battery housings. Their unique combination of thermal management and electrical resistance supports safety and performance in automotive and telecommunications industries.

Plastics Used for Electrical Insulation

Plastics used for electrical insulation exhibit low electrical conductivity, making them excellent insulators that prevent the flow of electric current. Their thermal conductivity is generally low to moderate, allowing them to effectively manage heat dissipation in electronic components without transferring excessive heat. Common insulating plastics like polyethylene, polypropylene, and PVC combine electrical resistance with sufficient thermal stability, ensuring safety and performance in electrical applications.

Measuring Conductivity in Plastic Materials

Thermal conductivity in plastic materials is typically measured using techniques like the laser flash method, which evaluates heat transfer rates through the sample. Electrical conductivity is assessed using four-point probe or impedance spectroscopy methods to determine the material's ability to conduct electric current. Accurate measurement of both properties is critical for applications requiring thermal management or electrical insulation performance in polymer-based components.

Material Selection: Balancing Thermal and Electrical Needs

Selecting plastics for applications requiring both thermal and electrical conductivity demands a careful balance, as most polymers exhibit low electrical conductivity but varying thermal conductivities depending on fillers like carbon fibers or metal particles. Materials such as graphite-filled polyethylene or silicone composites can enhance thermal transfer while maintaining electrical insulation or controlled conductivity. Evaluating these composites based on thermal conductivity values (typically 0.2 to 5 W/m*K) against their electrical resistivity can optimize performance in electronics, automotive, or thermal management systems.

Innovations Enhancing Conductivity in Plastics

Recent innovations in enhancing thermal and electrical conductivity in plastics include the incorporation of conductive fillers such as graphene, carbon nanotubes, and metal nanoparticles, which significantly improve performance without compromising mechanical properties. Advanced polymer composites leveraging nanotechnology enable tailored conductivity levels for applications in flexible electronics, heat dissipation, and electromagnetic interference shielding. These developments facilitate the use of plastics in high-performance electronic devices and sustainable energy solutions by combining lightweight properties with enhanced conductive capabilities.

Thermal Conductivity vs Electrical Conductivity Infographic

materialdif.com

materialdif.com