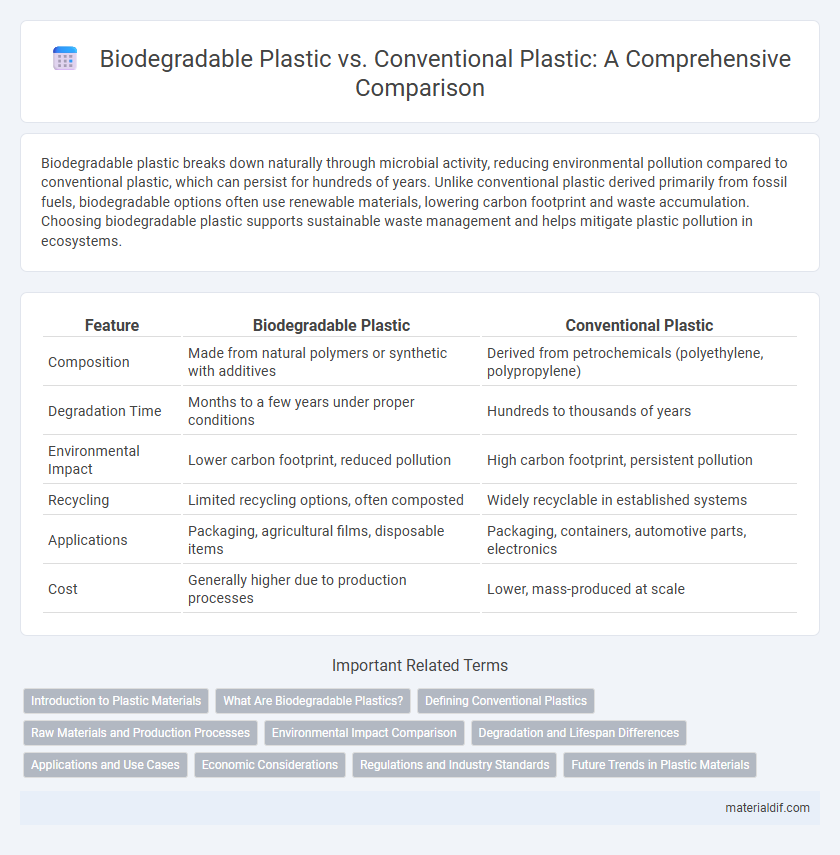

Biodegradable plastic breaks down naturally through microbial activity, reducing environmental pollution compared to conventional plastic, which can persist for hundreds of years. Unlike conventional plastic derived primarily from fossil fuels, biodegradable options often use renewable materials, lowering carbon footprint and waste accumulation. Choosing biodegradable plastic supports sustainable waste management and helps mitigate plastic pollution in ecosystems.

Table of Comparison

| Feature | Biodegradable Plastic | Conventional Plastic |

|---|---|---|

| Composition | Made from natural polymers or synthetic with additives | Derived from petrochemicals (polyethylene, polypropylene) |

| Degradation Time | Months to a few years under proper conditions | Hundreds to thousands of years |

| Environmental Impact | Lower carbon footprint, reduced pollution | High carbon footprint, persistent pollution |

| Recycling | Limited recycling options, often composted | Widely recyclable in established systems |

| Applications | Packaging, agricultural films, disposable items | Packaging, containers, automotive parts, electronics |

| Cost | Generally higher due to production processes | Lower, mass-produced at scale |

Introduction to Plastic Materials

Biodegradable plastic is designed to break down naturally through microbial activity, reducing environmental impact compared to conventional plastic, which is derived from petroleum and persists in ecosystems for hundreds of years. Conventional plastics like polyethylene and polypropylene offer durability and versatility but contribute significantly to plastic pollution and landfill accumulation. Innovations in biodegradable polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), aim to balance functional performance with eco-friendly degradation properties.

What Are Biodegradable Plastics?

Biodegradable plastics are materials designed to break down naturally through the action of microorganisms, such as bacteria and fungi, within a specific time frame under certain environmental conditions. Unlike conventional plastics made from petroleum-based polymers that persist for hundreds of years, biodegradable plastics can decompose into water, carbon dioxide, and biomass, reducing long-term pollution. These plastics are typically derived from renewable biomass sources like cornstarch, sugarcane, or cellulose, enhancing sustainability by minimizing reliance on fossil fuels.

Defining Conventional Plastics

Conventional plastics are synthetic polymers derived primarily from petrochemicals such as crude oil and natural gas, characterized by their durability, versatility, and resistance to degradation. These plastics, including polyethylene, polypropylene, and polystyrene, are widely used in packaging, automotive, and consumer goods due to their cost-effectiveness and mechanical properties. However, their long environmental persistence leads to significant pollution and waste management challenges.

Raw Materials and Production Processes

Biodegradable plastics are primarily derived from renewable biomass sources such as corn starch, sugarcane, or cellulose, employing fermentation and polymerization in their production processes. Conventional plastics are synthesized from petrochemicals obtained through the refining of crude oil and natural gas, involving polymerization techniques like addition or condensation polymerization. The reliance on bio-based raw materials in biodegradable plastics reduces fossil fuel dependency and enhances environmental sustainability compared to the petrochemical-based raw materials used in conventional plastic production.

Environmental Impact Comparison

Biodegradable plastics break down more quickly in natural environments, significantly reducing landfill accumulation and soil pollution compared to conventional plastics, which can persist for hundreds of years. Conventional plastics contribute heavily to ocean pollution and microplastic formation, harming marine ecosystems and biodiversity. Lifecycle analyses reveal that biodegradable plastics generally have a lower carbon footprint due to reduced fossil fuel usage and enhanced compostability, but their environmental benefits depend on proper disposal conditions.

Degradation and Lifespan Differences

Biodegradable plastics break down through microbial activity within months to a few years, significantly reducing environmental persistence compared to conventional plastics, which can take hundreds to thousands of years to degrade. The degradation process for biodegradable plastics depends on factors like temperature, humidity, and microbial presence, whereas conventional plastics mainly degrade through slow photodegradation and mechanical fragmentation. This rapid degradation of biodegradable plastics helps mitigate long-term pollution and accumulation in ecosystems, contrasting sharply with the extensive environmental footprint of conventional plastics.

Applications and Use Cases

Biodegradable plastics are primarily utilized in packaging, agricultural films, and disposable cutlery, offering an eco-friendly alternative that decomposes naturally in composting environments. Conventional plastics dominate applications requiring durability and long-term use, such as automotive parts, electronic casings, and household appliances, due to their strength and resistance to degradation. The choice between biodegradable and conventional plastics depends on the specific use case, balancing environmental impact with performance requirements.

Economic Considerations

Biodegradable plastics often incur higher production costs compared to conventional plastics due to expensive raw materials and specialized manufacturing processes, impacting market price competitiveness. Conventional plastics benefit from established supply chains and economies of scale, making them more affordable for mass production and widespread use. Investment in biodegradable plastic technology and policy incentives are critical to reduce costs and promote sustainable alternatives in the plastic industry.

Regulations and Industry Standards

Biodegradable plastic is increasingly subject to stringent regulations such as ASTM D6400 and EN 13432, which define compostability criteria and environmental safety standards. Conventional plastic manufacturing adheres to global standards like ISO 14001 for environmental management but faces tightening restrictions due to pollution concerns and waste management policies. Industry standards are evolving to promote transparent labeling and recycling protocols, driving innovation in bioplastics and reducing reliance on fossil-fuel-based materials.

Future Trends in Plastic Materials

Future trends in plastic materials prioritize biodegradable plastics due to increasing environmental regulations and consumer demand for sustainable solutions. Innovations in biopolymers and enzymatic degradation technologies aim to enhance the performance and degradation rates of biodegradable plastics compared to conventional polymers like polyethylene and polypropylene. Industry forecasts predict a significant market growth for biodegradable plastics, driven by advancements in recycling infrastructure and circular economy initiatives.

Biodegradable Plastic vs Conventional Plastic Infographic

materialdif.com

materialdif.com