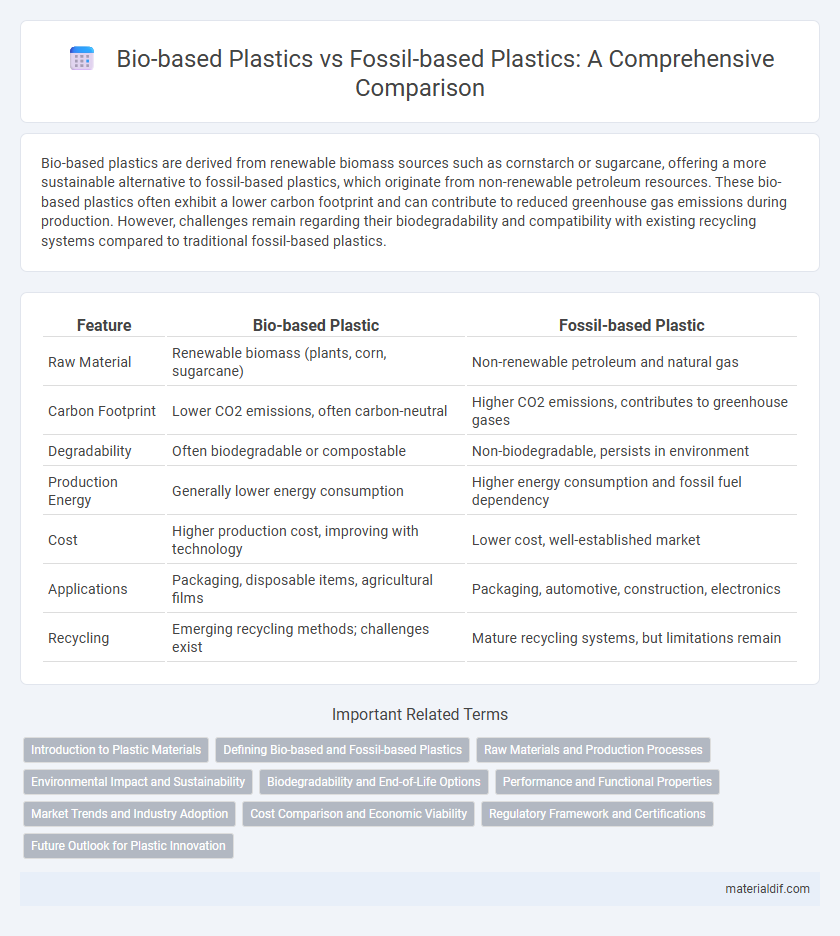

Bio-based plastics are derived from renewable biomass sources such as cornstarch or sugarcane, offering a more sustainable alternative to fossil-based plastics, which originate from non-renewable petroleum resources. These bio-based plastics often exhibit a lower carbon footprint and can contribute to reduced greenhouse gas emissions during production. However, challenges remain regarding their biodegradability and compatibility with existing recycling systems compared to traditional fossil-based plastics.

Table of Comparison

| Feature | Bio-based Plastic | Fossil-based Plastic |

|---|---|---|

| Raw Material | Renewable biomass (plants, corn, sugarcane) | Non-renewable petroleum and natural gas |

| Carbon Footprint | Lower CO2 emissions, often carbon-neutral | Higher CO2 emissions, contributes to greenhouse gases |

| Degradability | Often biodegradable or compostable | Non-biodegradable, persists in environment |

| Production Energy | Generally lower energy consumption | Higher energy consumption and fossil fuel dependency |

| Cost | Higher production cost, improving with technology | Lower cost, well-established market |

| Applications | Packaging, disposable items, agricultural films | Packaging, automotive, construction, electronics |

| Recycling | Emerging recycling methods; challenges exist | Mature recycling systems, but limitations remain |

Introduction to Plastic Materials

Bio-based plastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, offering a sustainable alternative to fossil-based plastics made from petroleum or natural gas. These materials reduce carbon footprint by utilizing organic carbon, whereas fossil-based plastics rely on finite, non-renewable fossil resources that contribute to greenhouse gas emissions. Innovations in polymer chemistry enable bio-based plastics to achieve comparable performance characteristics, promoting their integration into packaging, agriculture, and consumer goods industries.

Defining Bio-based and Fossil-based Plastics

Bio-based plastics are derived from renewable biomass sources such as corn, sugarcane, or cellulose, offering a sustainable alternative to traditional plastics. Fossil-based plastics, primarily made from non-renewable petroleum and natural gas, dominate the current global plastic production due to established infrastructure and cost efficiency. The key distinction lies in their raw material origin, influencing environmental impact, biodegradability, and carbon footprint.

Raw Materials and Production Processes

Bio-based plastics derive primarily from renewable biomass sources such as corn starch, sugarcane, and cellulose, offering a sustainable alternative to conventional fossil-based plastics made from petroleum and natural gas. The production process of bio-based plastics involves fermentation or polymerization of bio-derived monomers, reducing carbon emissions compared to the energy-intensive refining and cracking procedures used for fossil-based plastics. While bio-based plastics utilize renewable raw materials and often have lower environmental impact in production, fossil-based plastics benefit from established infrastructure and cost efficiencies in large-scale synthesis.

Environmental Impact and Sustainability

Bio-based plastics, derived from renewable biomass such as corn or sugarcane, significantly reduce carbon emissions compared to fossil-based plastics produced from petroleum. Their biodegradability and lower reliance on finite resources enhance sustainability by minimizing long-term environmental pollution and resource depletion. However, bio-based plastics may still compete with agricultural land use and require energy-intensive processing, necessitating careful life cycle assessments for true environmental benefit.

Biodegradability and End-of-Life Options

Bio-based plastics, derived from renewable biomass like corn or sugarcane, often offer enhanced biodegradability compared to fossil-based plastics, which primarily consist of petroleum-derived polymers resistant to natural degradation. End-of-life options for bio-based plastics include composting and anaerobic digestion, enabling them to break down under controlled conditions, whereas fossil-based plastics typically require mechanical recycling or landfilling, contributing to long-term environmental persistence. However, not all bio-based plastics are fully biodegradable, necessitating specific waste management infrastructure to optimize their environmental benefits.

Performance and Functional Properties

Bio-based plastics often match or exceed the performance and functional properties of fossil-based plastics, including tensile strength, durability, and thermal resistance, making them suitable for a wide range of applications. Many bio-based plastics demonstrate excellent barrier properties against oxygen and moisture, which is critical for food packaging and medical uses. Advances in bio-polymer technology continue to improve the mechanical and chemical resistance of bio-based plastics, narrowing the gap with traditional fossil-based materials.

Market Trends and Industry Adoption

The bio-based plastic market is experiencing rapid growth driven by increasing consumer demand for sustainable alternatives and stricter environmental regulations targeting fossil-based plastics. Major industries, including packaging, automotive, and consumer goods, are accelerating the adoption of bio-based plastics to reduce carbon footprints and comply with circular economy principles. Market forecasts project that bio-based plastics will capture a significant share of the global plastics market by 2030, supported by advancements in biopolymer technologies and expanding production capacities.

Cost Comparison and Economic Viability

Bio-based plastics generally incur higher production costs than fossil-based plastics due to feedstock expenses and less mature manufacturing processes. Fossil-based plastics benefit from established supply chains and economies of scale, making them more economically viable for large-scale applications. Ongoing advancements and increasing raw material prices could narrow the cost gap, enhancing the competitiveness of bio-based plastics in the market.

Regulatory Framework and Certifications

Bio-based plastics benefit from emerging regulatory frameworks such as the European Union's Single-Use Plastics Directive and the US Federal Trade Commission's Green Guides, which promote sustainability and material transparency. Certifications like ASTM D6866 for biobased content and TUV Austria's OK Compost label ensure compliance with biodegradability and renewable resource claims. Fossil-based plastics continue to face increasing regulatory scrutiny due to environmental concerns, driving demand for certified bio-based alternatives.

Future Outlook for Plastic Innovation

Bio-based plastics are projected to experience significant growth due to increasing environmental regulations and consumer demand for sustainable materials, with innovations targeting enhanced biodegradability and performance parity with fossil-based plastics. Advances in biotechnology and materials science are driving breakthroughs in feedstock diversification and recycling methods, reducing reliance on fossil fuels and lowering carbon footprints. The integration of bio-based plastics in circular economy models is expected to reshape global plastics markets, fostering cleaner production and waste management practices.

Bio-based Plastic vs Fossil-based Plastic Infographic

materialdif.com

materialdif.com