Antistatic plastic additives reduce surface static electricity by attracting moisture from the air, preventing dust and dirt accumulation without significantly altering the material's electrical properties. Conductive plastic fillers, such as carbon black or metal powders, create conductive pathways within the polymer matrix, enabling efficient dissipation of static charge and enhancing electrical conductivity. Choosing between these options depends on the required level of conductivity and the application's specific performance criteria.

Table of Comparison

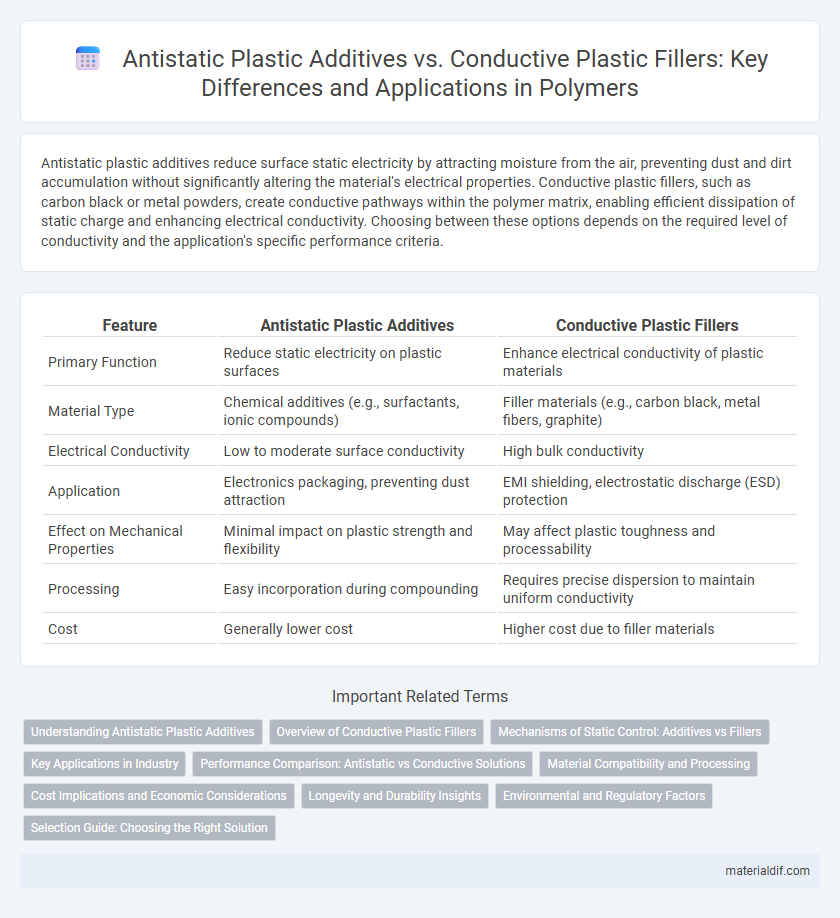

| Feature | Antistatic Plastic Additives | Conductive Plastic Fillers |

|---|---|---|

| Primary Function | Reduce static electricity on plastic surfaces | Enhance electrical conductivity of plastic materials |

| Material Type | Chemical additives (e.g., surfactants, ionic compounds) | Filler materials (e.g., carbon black, metal fibers, graphite) |

| Electrical Conductivity | Low to moderate surface conductivity | High bulk conductivity |

| Application | Electronics packaging, preventing dust attraction | EMI shielding, electrostatic discharge (ESD) protection |

| Effect on Mechanical Properties | Minimal impact on plastic strength and flexibility | May affect plastic toughness and processability |

| Processing | Easy incorporation during compounding | Requires precise dispersion to maintain uniform conductivity |

| Cost | Generally lower cost | Higher cost due to filler materials |

Understanding Antistatic Plastic Additives

Antistatic plastic additives reduce static charge buildup on plastic surfaces by increasing surface conductivity without significantly altering the material's bulk properties, making them ideal for applications where surface protection and clarity are crucial. These additives often include ionic compounds or surfactants that attract moisture from the environment, creating a thin conductive layer to dissipate static electricity effectively. Understanding the mechanism and appropriate selection of antistatic additives ensures improved product performance in electronics, packaging, and automotive industries where static control is essential.

Overview of Conductive Plastic Fillers

Conductive plastic fillers enhance electrical conductivity by integrating materials such as carbon black, carbon fibers, or metal powders into the polymer matrix, creating pathways for electron flow. Unlike antistatic additives that primarily reduce surface static buildup, conductive fillers provide bulk conductivity, making them suitable for applications requiring electromagnetic interference (EMI) shielding or electrostatic discharge (ESD) protection. These fillers influence mechanical properties and processing behavior, necessitating precise formulation to balance conductivity with material performance.

Mechanisms of Static Control: Additives vs Fillers

Antistatic plastic additives reduce surface resistivity by migrating to the surface, attracting moisture to dissipate static charges effectively. Conductive plastic fillers, such as carbon black or metal fibers, form a permanent conductive network within the polymer matrix, enabling bulk conductivity and rapid static charge dissipation. The key difference lies in the additives' surface-level, temporary static control versus the fillers' bulk, long-lasting conductive pathways enhancing electromagnetic interference shielding.

Key Applications in Industry

Antistatic plastic additives are primarily used in packaging, electronics housings, and medical devices to prevent static charge buildup and protect sensitive components. Conductive plastic fillers find key applications in electromagnetic interference (EMI) shielding, automotive components, and industrial machinery where enhanced electrical conductivity is required. Both materials improve safety and functionality across electronics, automotive, and packaging industries by addressing static control and electrical conductivity needs.

Performance Comparison: Antistatic vs Conductive Solutions

Antistatic plastic additives reduce surface resistivity to prevent static charge build-up, making them ideal for applications requiring moderate static control and improved aesthetics without compromising material clarity. Conductive plastic fillers, such as carbon black or metal fibers, provide lower volume resistivity, enabling efficient dissipation of electrical charge for high-performance applications demanding robust electromagnetic interference (EMI) shielding or electrical conductivity. Performance comparison highlights that antistatic additives suit consumer electronics packaging and preventing dust attraction, whereas conductive fillers deliver superior conductivity critical for industrial components and electronic housings.

Material Compatibility and Processing

Antistatic plastic additives, typically low molecular weight compounds or surface-active agents, enhance material compatibility by integrating seamlessly into various polymer matrices without altering mechanical properties, enabling easy processing through conventional thermoplastic methods. Conductive plastic fillers, such as carbon black, carbon nanotubes, or metal fibers, require careful dispersion to maintain uniform conductivity, often demanding adjustments in processing parameters like temperature and shear to prevent filler agglomeration and ensure consistent electrical performance. Selecting between antistatic additives and conductive fillers depends on the target surface resistance, with antistatic additives suited for moderate static dissipation and conductive fillers necessary for applications requiring higher conductivity and electromagnetic interference shielding.

Cost Implications and Economic Considerations

Antistatic plastic additives offer a cost-effective solution by enhancing surface conductivity at low concentrations, reducing material expenses compared to conductive plastic fillers that require higher loadings of costly conductive materials like carbon black or metal fibers. Conductive fillers provide superior conductivity and durability but significantly increase manufacturing costs due to the need for specialized processing and higher raw material prices. Economic considerations favor antistatic additives for applications with moderate conductivity requirements, while conductive fillers justify their expense in high-performance or critical antistatic environments.

Longevity and Durability Insights

Antistatic plastic additives enhance surface conductivity by reducing static charge buildup, offering long-lasting performance under low stress conditions. Conductive plastic fillers, such as carbon black or metal fibers, create a conductive network within the polymer matrix, providing superior durability and consistent conductivity in harsh environments. Longevity of conductive fillers surpasses antistatic additives due to their stable integration, making them ideal for applications requiring persistent electrical conductivity and mechanical robustness.

Environmental and Regulatory Factors

Antistatic plastic additives typically consist of surface-active agents that reduce static charge without significantly altering the polymer's bulk properties, offering easier compliance with environmental regulations due to their lower heavy metal content. Conductive plastic fillers, such as carbon black, graphite, or metal particles, provide permanent electrical conductivity but often face stricter regulatory scrutiny and disposal challenges associated with potentially hazardous substances and increased environmental footprint. Choosing between antistatic additives and conductive fillers requires careful consideration of lifecycle impacts, regulatory frameworks like REACH and RoHS, and end-of-life recyclability to minimize ecological harm.

Selection Guide: Choosing the Right Solution

Antistatic plastic additives reduce surface resistivity by attracting moisture to dissipate static charge, making them ideal for applications requiring minimal conductivity and effective static control without altering mechanical properties. Conductive plastic fillers, such as carbon black or metal particles, create conductive pathways for higher electrical conductivity, suited for electromagnetic interference (EMI) shielding and electrostatic discharge (ESD) protection in demanding environments. Choosing the right solution depends on factors like required conductivity levels, environmental conditions, mechanical property retention, and cost constraints for optimal performance.

Antistatic Plastic Additives vs Conductive Plastic Fillers Infographic

materialdif.com

materialdif.com