Cross-linked polyethylene (PEX) offers enhanced thermal resistance and improved mechanical strength compared to linear polyethylene (PE), making it ideal for applications requiring durability and heat tolerance. Unlike linear polyethylene, which has a more flexible and less dense molecular structure, PEX undergoes a chemical cross-linking process that creates a three-dimensional network, resulting in superior chemical resistance and reduced permeability. These properties make cross-linked polyethylene preferable for demanding uses such as plumbing and insulation, while linear polyethylene remains favored for packaging and everyday plastic containers.

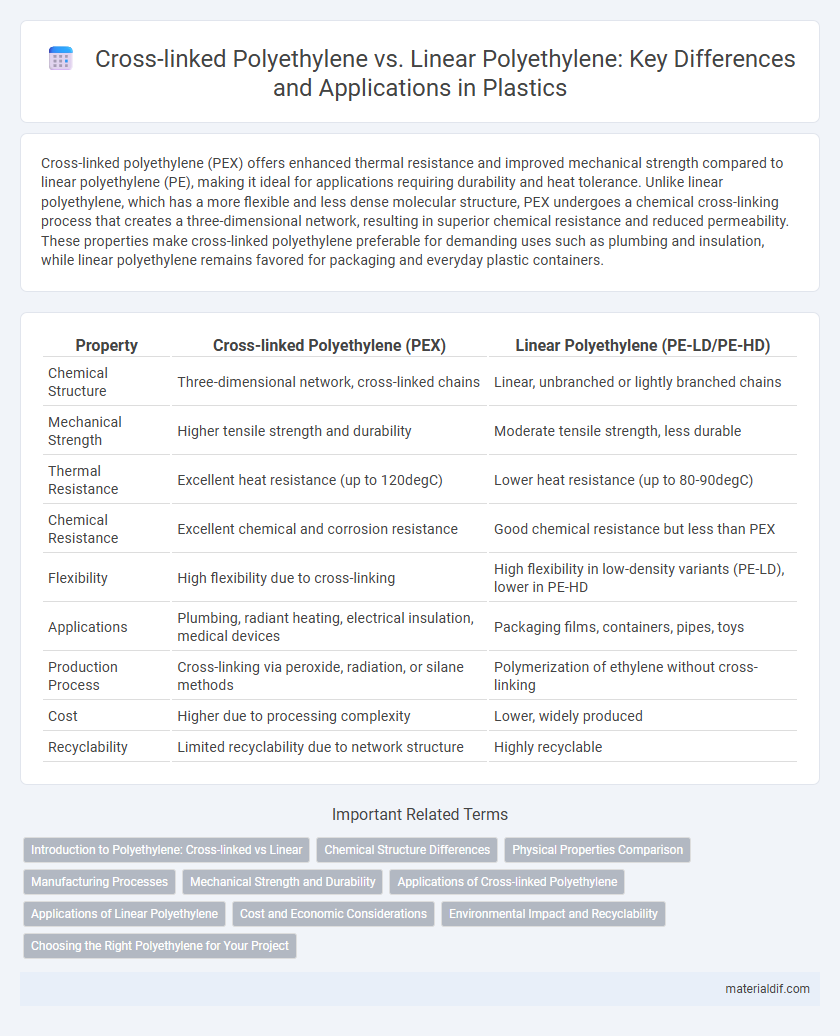

Table of Comparison

| Property | Cross-linked Polyethylene (PEX) | Linear Polyethylene (PE-LD/PE-HD) |

|---|---|---|

| Chemical Structure | Three-dimensional network, cross-linked chains | Linear, unbranched or lightly branched chains |

| Mechanical Strength | Higher tensile strength and durability | Moderate tensile strength, less durable |

| Thermal Resistance | Excellent heat resistance (up to 120degC) | Lower heat resistance (up to 80-90degC) |

| Chemical Resistance | Excellent chemical and corrosion resistance | Good chemical resistance but less than PEX |

| Flexibility | High flexibility due to cross-linking | High flexibility in low-density variants (PE-LD), lower in PE-HD |

| Applications | Plumbing, radiant heating, electrical insulation, medical devices | Packaging films, containers, pipes, toys |

| Production Process | Cross-linking via peroxide, radiation, or silane methods | Polymerization of ethylene without cross-linking |

| Cost | Higher due to processing complexity | Lower, widely produced |

| Recyclability | Limited recyclability due to network structure | Highly recyclable |

Introduction to Polyethylene: Cross-linked vs Linear

Cross-linked polyethylene (PEX) features a chemically bonded network structure, enhancing thermal resistance and mechanical strength compared to linear polyethylene (PE), which consists of unbranched chains offering flexibility and ease of processing. PEX is widely used in plumbing, radiant heating, and electrical insulation due to its durability and resistance to deformation under heat. In contrast, linear polyethylene types such as LDPE and HDPE are favored for packaging, containers, and films because of their clarity, toughness, and versatility.

Chemical Structure Differences

Cross-linked polyethylene (PEX) features a three-dimensional network of covalent bonds formed through cross-linking processes, enhancing its thermal resistance and mechanical strength compared to linear polyethylene (PE), which consists of long, unbranched chains with only van der Waals forces between them. Linear polyethylene exhibits higher crystallinity and density due to its uniform chain arrangement, resulting in greater tensile strength but lower flexibility than the thermoset structure of PEX. The chemical cross-linking in PEX creates a stable network that resists deformation and chemical attack, distinguishing it from the thermoplastic and more easily processed linear polyethylene.

Physical Properties Comparison

Cross-linked polyethylene (PEX) exhibits superior thermal resistance and mechanical strength compared to linear polyethylene (PE), making it ideal for high-temperature applications. PEX's networked molecular structure enhances its impact resistance, elasticity, and dimensional stability, whereas linear PE demonstrates higher crystallinity and density, resulting in greater tensile strength but lower flexibility. The cross-linking process in PEX reduces creep and improves chemical resistance, distinguishing it from the more linear, thermoplastic nature of standard polyethylene.

Manufacturing Processes

Cross-linked polyethylene (PEX) is manufactured through chemical or physical cross-linking methods such as peroxide, silane, or radiation cross-linking, which create covalent bonds between polymer chains to enhance thermal and mechanical properties. Linear polyethylene, including low-density (LDPE) and high-density polyethylene (HDPE), is produced primarily by polymerization of ethylene using catalysts like Ziegler-Natta or metallocene in processes such as gas-phase, solution, or slurry polymerization, resulting in linear, non-cross-linked chains. The cross-linking in PEX improves chemical resistance and temperature stability, whereas linear polyethylene offers ease of processing and recyclability.

Mechanical Strength and Durability

Cross-linked polyethylene (PEX) exhibits superior mechanical strength and enhanced durability compared to linear polyethylene (LDPE and HDPE), due to its three-dimensional network structure that resists deformation and cracking under stress. The covalent bonds in PEX provide high resistance to abrasion, impact, and thermal cycling, making it ideal for demanding applications such as piping and insulation. Linear polyethylene offers flexibility and ease of processing but generally lacks the long-term mechanical robustness and chemical resistance found in cross-linked variants.

Applications of Cross-linked Polyethylene

Cross-linked polyethylene (PEX) is widely used in plumbing, radiant heating systems, and medical devices due to its enhanced thermal resistance and superior chemical stability compared to linear polyethylene (PE). Its cross-linked structure provides excellent durability and flexibility, making it ideal for hot water pipes and insulation in electrical cables. PEX also shows increased resistance to stress cracking, which extends its lifespan in demanding industrial applications.

Applications of Linear Polyethylene

Linear polyethylene is widely used in packaging films, plastic bags, and containers due to its excellent tensile strength and clarity. Its flexibility and chemical resistance make it ideal for agricultural mulch films and food packaging applications. Unlike cross-linked polyethylene, linear polyethylene processes easily via extrusion and molding, supporting a broad range of consumer and industrial uses.

Cost and Economic Considerations

Cross-linked polyethylene (PEX) typically incurs higher production and installation costs compared to linear polyethylene (PE-LD or PE-HD) due to its complex manufacturing process and enhanced chemical structure. The improved thermal stability and mechanical strength of PEX justify the premium in applications demanding durability, yet linear polyethylene remains more economically viable for large-scale, low-stress packaging and piping solutions. Choosing between PEX and linear polyethylene hinges on balancing upfront expenses against long-term performance benefits, with economic considerations varying based on specific industry requirements and lifecycle cost analysis.

Environmental Impact and Recyclability

Cross-linked polyethylene (PEX) is less recyclable than linear polyethylene (PE) due to its chemically bonded network structure, which resists melting and remolding processes. Linear polyethylene, particularly high-density polyethylene (HDPE), is widely recycled through mechanical recycling, contributing to lower environmental impact. The production and disposal of PEX materials generate more challenges in waste management, making linear polyethylene a more environmentally sustainable choice.

Choosing the Right Polyethylene for Your Project

Cross-linked polyethylene (PEX) offers superior thermal resistance and enhanced durability, making it ideal for plumbing and radiant heating systems that require flexibility under high temperatures. Linear polyethylene (HDPE) provides excellent chemical resistance and tensile strength, suited for applications like piping, containers, and geomembranes where rigidity and chemical stability are essential. Selecting the right polyethylene depends on project-specific factors such as temperature exposure, mechanical stress, and chemical compatibility to ensure optimal performance and longevity.

Cross-linked Polyethylene vs Linear Polyethylene Infographic

materialdif.com

materialdif.com