Pelletizing involves converting shredded plastic waste into uniform pellets, making it easier to handle and transport for recycling or manufacturing. Compounding combines plastic pellets with additives, fillers, or reinforcements to enhance material properties for specific applications. Understanding the differences between pelletizing and compounding is crucial for optimizing plastic pet recycling and production processes.

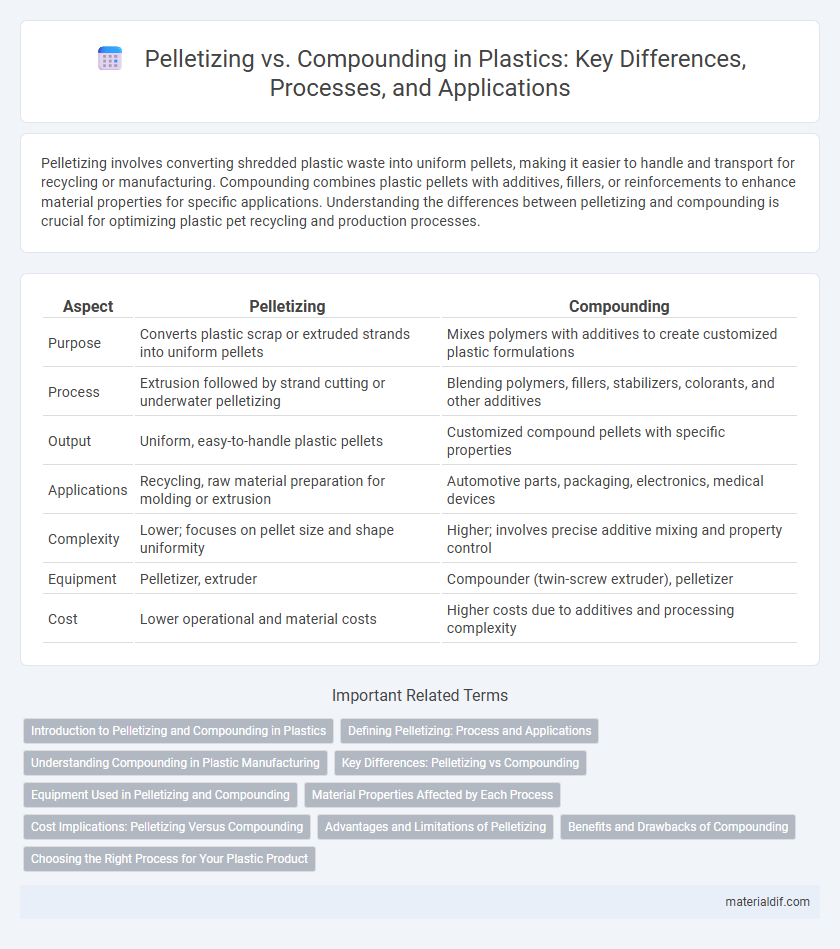

Table of Comparison

| Aspect | Pelletizing | Compounding |

|---|---|---|

| Purpose | Converts plastic scrap or extruded strands into uniform pellets | Mixes polymers with additives to create customized plastic formulations |

| Process | Extrusion followed by strand cutting or underwater pelletizing | Blending polymers, fillers, stabilizers, colorants, and other additives |

| Output | Uniform, easy-to-handle plastic pellets | Customized compound pellets with specific properties |

| Applications | Recycling, raw material preparation for molding or extrusion | Automotive parts, packaging, electronics, medical devices |

| Complexity | Lower; focuses on pellet size and shape uniformity | Higher; involves precise additive mixing and property control |

| Equipment | Pelletizer, extruder | Compounder (twin-screw extruder), pelletizer |

| Cost | Lower operational and material costs | Higher costs due to additives and processing complexity |

Introduction to Pelletizing and Compounding in Plastics

Pelletizing and compounding are essential processes in plastics manufacturing that enhance material handling and performance. Pelletizing transforms molten plastic into uniform granules for easier feeding and transport, while compounding involves blending polymers with additives to achieve specific physical and chemical properties. Both techniques optimize production efficiency and tailor plastic materials for diverse industrial applications.

Defining Pelletizing: Process and Applications

Pelletizing in plastics involves converting raw plastic materials into small, uniform pellets through processes like extrusion or cutting, enabling easier handling, transportation, and controlled melting during manufacturing. These pellets serve as standardized feedstock for applications such as injection molding, blow molding, and extrusion, ensuring consistent material quality and process efficiency. The process enhances material homogeneity and facilitates blending with additives, improving the mechanical and aesthetic properties of the final plastic products.

Understanding Compounding in Plastic Manufacturing

Compounding in plastic manufacturing involves blending polymers with additives such as fillers, stabilizers, and colorants to enhance material properties and performance for specific applications. This process ensures uniform dispersion of ingredients, resulting in customized plastic formulations tailored for durability, flexibility, or chemical resistance. Unlike pelletizing, which mainly forms uniform plastic pellets from molten polymers, compounding integrates functional enhancements critical for advanced plastic products.

Key Differences: Pelletizing vs Compounding

Pelletizing involves converting plastic resins into small, uniform pellets for easier handling and processing, while compounding combines base polymers with additives to enhance material properties and performance. Pelletizing focuses on size reduction and standardization, whereas compounding tailors plastic formulations to specific application requirements by mixing fillers, stabilizers, and colorants. The primary difference lies in pelletizing preparing raw materials for manufacturing, while compounding customizes the polymer blend for optimized functionality.

Equipment Used in Pelletizing and Compounding

Pelletizing equipment includes strand pelletizers, underwater pelletizers, and air-cooled pelletizers, designed to transform molten plastic into uniform pellets for easier handling and processing. Compounding machinery involves twin-screw extruders and batch mixers that blend polymers with additives, fillers, and reinforcements to tailor material properties. The choice of equipment directly impacts the efficiency, consistency, and quality of the final plastic products in the manufacturing process.

Material Properties Affected by Each Process

Pelletizing primarily affects the uniformity and ease of handling of plastic materials, ensuring consistent particle size and improved flow characteristics for further processing. Compounding modifies material properties by incorporating additives, fillers, or reinforcements, enhancing mechanical strength, thermal stability, and chemical resistance. The choice between pelletizing and compounding significantly influences the final plastic product's performance and application suitability.

Cost Implications: Pelletizing Versus Compounding

Pelletizing reduces transportation and handling costs by converting plastic materials into uniform pellets that facilitate easier storage and automated processing. Compounding involves the addition of additives and fillers during production, increasing raw material expenses but enhancing product performance, which can justify higher initial costs. Choosing between pelletizing and compounding depends on balancing upfront investment with long-term efficiency and product quality requirements.

Advantages and Limitations of Pelletizing

Pelletizing offers advantages such as improved material handling, consistent size and shape for uniform feeding, and enhanced melting efficiency during processing, which reduces waste and energy consumption. Limitations include potential degradation of sensitive polymers due to heat exposure during the pelletizing process and the additional cost of pelletizing equipment and maintenance. This method is less favorable for highly filled or abrasive materials that can cause wear on equipment and irregular pellet shapes.

Benefits and Drawbacks of Compounding

Compounding enhances plastic properties by blending polymers with additives, fillers, and reinforcements, resulting in materials tailored for specific applications with improved strength, flexibility, and durability. The process allows for customization but involves higher complexity, increased production costs, and longer processing times compared to pelletizing. Despite these drawbacks, compounding offers superior control over material characteristics, making it ideal for advanced manufacturing requirements.

Choosing the Right Process for Your Plastic Product

Pelletizing involves converting raw plastic resin into uniform pellets, optimizing ease of handling and consistent melting during downstream processing. Compounding integrates additives like colorants, stabilizers, and fillers into the plastic matrix, enhancing material properties for specific applications. Selecting the right process depends on product requirements such as mechanical strength, aesthetic qualities, and processing efficiency to achieve targeted performance and cost-effectiveness.

Pelletizing vs Compounding Infographic

materialdif.com

materialdif.com