ABS offers superior impact resistance and durability compared to HIPS, making it ideal for heavy-duty plastic pet applications. HIPS provides excellent ease of fabrication and cost-effectiveness, favored for lightweight or less-demanding pet components. Selecting between ABS and HIPS depends on balancing performance requirements with budget considerations in plastic pet manufacturing.

Table of Comparison

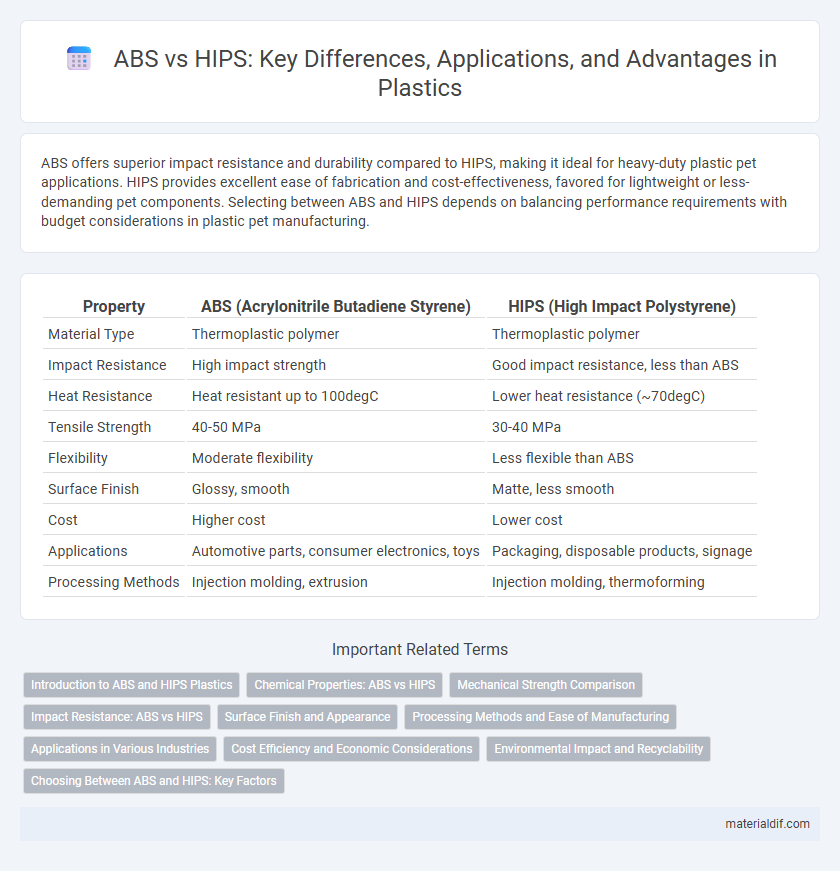

| Property | ABS (Acrylonitrile Butadiene Styrene) | HIPS (High Impact Polystyrene) |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic polymer |

| Impact Resistance | High impact strength | Good impact resistance, less than ABS |

| Heat Resistance | Heat resistant up to 100degC | Lower heat resistance (~70degC) |

| Tensile Strength | 40-50 MPa | 30-40 MPa |

| Flexibility | Moderate flexibility | Less flexible than ABS |

| Surface Finish | Glossy, smooth | Matte, less smooth |

| Cost | Higher cost | Lower cost |

| Applications | Automotive parts, consumer electronics, toys | Packaging, disposable products, signage |

| Processing Methods | Injection molding, extrusion | Injection molding, thermoforming |

Introduction to ABS and HIPS Plastics

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic known for its impact resistance, toughness, and ease of machining, making it ideal for automotive parts, consumer electronics, and LEGO bricks. HIPS (High Impact Polystyrene) combines polystyrene with rubber to enhance durability and impact strength, frequently used in packaging, disposable cutlery, and appliance housings. Both plastics offer unique mechanical properties and processability advantages, with ABS providing superior heat resistance and HIPS favoring cost-effective manufacturing for high-volume applications.

Chemical Properties: ABS vs HIPS

ABS (Acrylonitrile Butadiene Styrene) offers superior chemical resistance to acids, alkalis, and oils compared to HIPS (High Impact Polystyrene), which is more vulnerable to organic solvents and alkalis. ABS also demonstrates higher thermal stability and impact resistance due to its acrylonitrile and butadiene components, making it suitable for harsher chemical environments. In contrast, HIPS is primarily valued for its ease of processing and cost-effectiveness but has comparatively lower chemical resistance and durability.

Mechanical Strength Comparison

ABS (Acrylonitrile Butadiene Styrene) exhibits higher tensile strength and impact resistance compared to HIPS (High Impact Polystyrene), making it more suitable for demanding mechanical applications. ABS typically offers tensile strength values around 40 MPa, whereas HIPS usually ranges between 20 to 30 MPa. The superior toughness and durability of ABS contribute to its preference in automotive parts, electronic housings, and consumer products requiring robust mechanical performance.

Impact Resistance: ABS vs HIPS

ABS (Acrylonitrile Butadiene Styrene) exhibits superior impact resistance compared to HIPS (High Impact Polystyrene) due to its rubber-like butadiene component, which absorbs and dissipates energy efficiently. HIPS offers good impact resistance but tends to be less durable under heavy mechanical stress and repeated impacts. ABS is preferred for applications requiring higher toughness and resilience, such as automotive parts and consumer electronics.

Surface Finish and Appearance

ABS plastic offers a smooth, glossy surface finish with excellent color retention, making it ideal for applications requiring high aesthetic appeal. HIPS provides a matte or satin finish that is less shiny but suitable for painting and post-processing due to its ease of machining. The choice between ABS and HIPS depends on the desired appearance and whether additional surface treatments are planned.

Processing Methods and Ease of Manufacturing

ABS (Acrylonitrile Butadiene Styrene) is commonly processed through injection molding and extrusion, offering excellent dimensional stability and impact resistance, which simplifies manufacturing for complex shapes. HIPS (High Impact Polystyrene) is easier to thermoform and vacuum mold due to its lower melting point and good flow properties, making it ideal for rapid prototyping and packaging applications. Both materials provide efficient manufacturing options, but ABS excels in structural applications, while HIPS is favored for cost-effective, lightweight parts.

Applications in Various Industries

ABS (Acrylonitrile Butadiene Styrene) is widely used in automotive parts, consumer electronics housings, and toys due to its impact resistance and toughness. HIPS (High Impact Polystyrene) is preferred in packaging, disposable cutlery, and appliance components because of its ease of thermoforming and cost-effectiveness. Both plastics serve critical roles in manufacturing, with ABS favored for durability and HIPS chosen for lightweight, economical applications across diverse industries.

Cost Efficiency and Economic Considerations

ABS (Acrylonitrile Butadiene Styrene) generally exhibits higher cost efficiency due to its superior durability and impact resistance, reducing the need for frequent replacements and repairs. HIPS (High Impact Polystyrene) offers lower initial material costs, making it economically advantageous for large-scale, low-stress applications with minimal mechanical demands. Choosing between ABS and HIPS depends on balancing upfront expenses with long-term performance requirements to optimize overall economic outcomes in manufacturing.

Environmental Impact and Recyclability

ABS (Acrylonitrile Butadiene Styrene) has a higher environmental impact compared to HIPS (High Impact Polystyrene) due to its more complex chemical composition and energy-intensive production process. HIPS is generally more recyclable, accepted by many municipal recycling programs, and can be efficiently reprocessed into various consumer products. Both plastics pose challenges in biodegradability, but HIPS often results in lower landfill persistence, making it a more sustainable choice in waste management.

Choosing Between ABS and HIPS: Key Factors

Choosing between ABS and HIPS depends on factors such as impact resistance, surface finish, and cost-effectiveness. ABS offers superior strength and durability ideal for automotive and electronic housings, while HIPS provides excellent machinability and is more affordable for consumer goods and packaging. Evaluating the specific application environment, mechanical requirements, and budget constraints ensures optimal material selection.

ABS vs HIPS Infographic

materialdif.com

materialdif.com