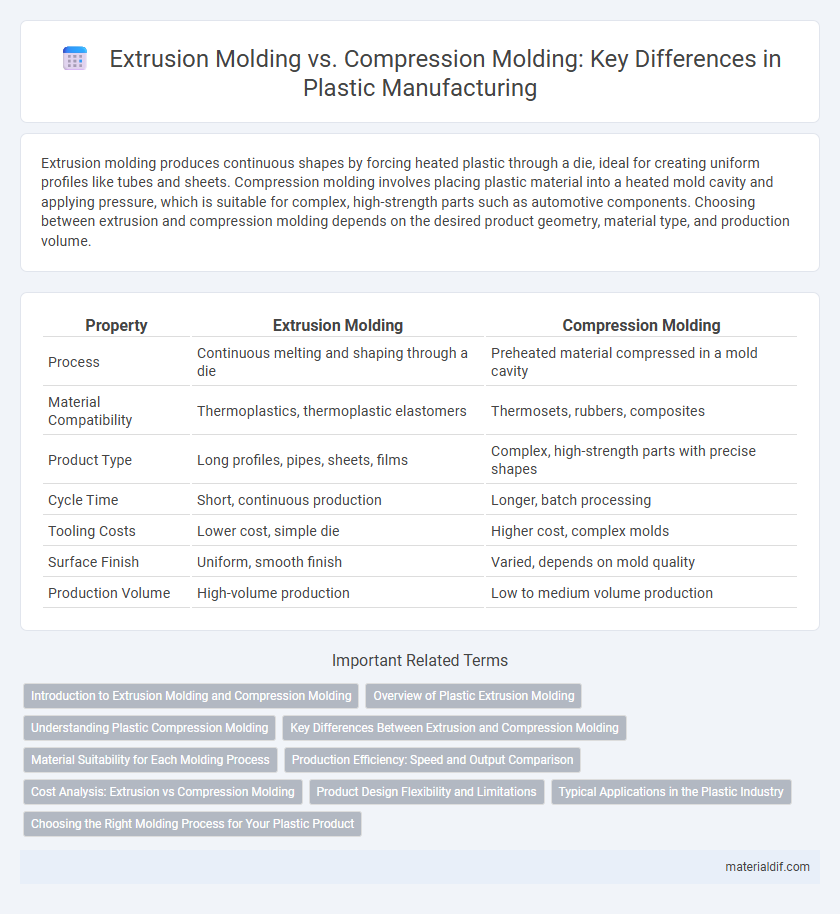

Extrusion molding produces continuous shapes by forcing heated plastic through a die, ideal for creating uniform profiles like tubes and sheets. Compression molding involves placing plastic material into a heated mold cavity and applying pressure, which is suitable for complex, high-strength parts such as automotive components. Choosing between extrusion and compression molding depends on the desired product geometry, material type, and production volume.

Table of Comparison

| Property | Extrusion Molding | Compression Molding |

|---|---|---|

| Process | Continuous melting and shaping through a die | Preheated material compressed in a mold cavity |

| Material Compatibility | Thermoplastics, thermoplastic elastomers | Thermosets, rubbers, composites |

| Product Type | Long profiles, pipes, sheets, films | Complex, high-strength parts with precise shapes |

| Cycle Time | Short, continuous production | Longer, batch processing |

| Tooling Costs | Lower cost, simple die | Higher cost, complex molds |

| Surface Finish | Uniform, smooth finish | Varied, depends on mold quality |

| Production Volume | High-volume production | Low to medium volume production |

Introduction to Extrusion Molding and Compression Molding

Extrusion molding is a continuous manufacturing process where heated plastic pellets are forced through a shaped die to create long, uniform profiles such as pipes, sheets, and films. Compression molding involves placing a measured amount of plastic material into a heated mold cavity, compressing it under high pressure to form complex, three-dimensional parts typically used in automotive and aerospace industries. Both processes serve distinct applications based on material type, production volume, and desired product geometry.

Overview of Plastic Extrusion Molding

Plastic extrusion molding involves melting raw plastic pellets and forcing them through a shaped die to create continuous profiles like pipes, sheets, or films. This process offers high efficiency for producing uniform cross-sectional shapes and is ideal for thermoplastics such as polyethylene, polypropylene, and PVC. Extrusion molding provides consistent dimensional accuracy and is widely used in manufacturing industries requiring long-length plastic components.

Understanding Plastic Compression Molding

Plastic compression molding involves placing heated plastic material into a heated mold cavity, where pressure is applied to shape the material into the desired form. This process is ideal for producing large, high-strength parts with complex geometries and excellent surface finish. Compression molding differs from extrusion molding by offering superior control over part thickness and material properties, making it suitable for thermosetting plastics.

Key Differences Between Extrusion and Compression Molding

Extrusion molding continuously forces molten plastic through a shaped die to create long, uniform profiles, ideal for pipes and sheets, while compression molding involves placing a preheated plastic charge into a heated mold cavity and applying pressure to form complex, high-strength parts like automotive components. Extrusion offers rapid production rates with consistent cross-sections, whereas compression molding excels in creating intricate shapes with better mechanical properties due to uniform pressure application. Key differences also include extrusion's suitability for thermoplastics and compression molding's compatibility with thermosetting plastics and composites.

Material Suitability for Each Molding Process

Extrusion molding excels with thermoplastics like polyethylene, polypropylene, and PVC due to their ability to be continuously shaped under heat and pressure. Compression molding suits thermosetting plastics such as phenolic, epoxy, and silicone rubber, which require precise heat and pressure to cure into durable, high-strength components. Material selection directly impacts product performance, with extrusion favoring flexible, complex profiles and compression molding optimized for intricate, high-temperature-resistant parts.

Production Efficiency: Speed and Output Comparison

Extrusion molding offers higher production efficiency with continuous operation, enabling rapid output of long, uniform plastic profiles and films, ideal for large-scale manufacturing. Compression molding is slower due to cyclical batch processing but excels in producing complex, high-strength thermoset parts with precise dimensions. Overall, extrusion is preferred for speed and volume, while compression molding prioritizes quality and material performance for specialized applications.

Cost Analysis: Extrusion vs Compression Molding

Extrusion molding generally offers lower production costs for high-volume runs due to continuous processing and reduced material waste, making it ideal for long, uniform plastic profiles. Compression molding incurs higher initial tooling expenses and longer cycle times but can be more cost-effective for small-batch production with complex, high-strength parts requiring precise dimensional control. Evaluating cost analysis between extrusion and compression molding depends on factors such as production volume, material type, part geometry, and labor intensity.

Product Design Flexibility and Limitations

Extrusion molding offers high product design flexibility with continuous profiles, ideal for creating complex, uniform cross-sections but is limited in producing intricate shapes or varying thicknesses. Compression molding allows for greater versatility in shape complexity and thickness variations but imposes restrictions on fine detail and tight tolerances due to mold design and material flow constraints. Material selection and production volume significantly influence the choice between extrusion and compression molding for maximizing design flexibility and minimizing limitations.

Typical Applications in the Plastic Industry

Extrusion molding is widely used for manufacturing continuous profiles such as pipes, tubing, and sheets due to its efficiency in producing long, uniform shapes. Compression molding excels in producing complex, high-strength components like automotive parts, electrical insulators, and large industrial items, offering superior mechanical properties. Both methods serve critical roles in the plastic industry, with extrusion preferred for mass production of simple geometric shapes and compression molding chosen for detailed, durable parts.

Choosing the Right Molding Process for Your Plastic Product

Extrusion molding offers continuous production ideal for creating uniform plastic profiles like pipes and sheets, while compression molding provides superior strength and detail for complex, high-performance parts such as automotive components. Selecting the right molding process depends on factors including production volume, material type, and product complexity, with extrusion favored for thermoplastics and compression molding suited for thermosetting plastics. Understanding these distinctions ensures optimal mechanical properties, cost efficiency, and manufacturing precision tailored to your specific plastic product requirements.

Extrusion Molding vs Compression Molding Infographic

materialdif.com

materialdif.com