PVC-U and PVC-C are both types of rigid plastic used in pipe manufacturing, with PVC-U (unplasticized PVC) being the most common due to its excellent chemical resistance and affordability. PVC-C (chlorinated PVC) offers higher temperature tolerance and improved fire resistance, making it suitable for industrial applications with demanding heat and chemical exposure. Choosing between PVC-U and PVC-C depends on the specific environmental and mechanical requirements of the plastic pet system.

Table of Comparison

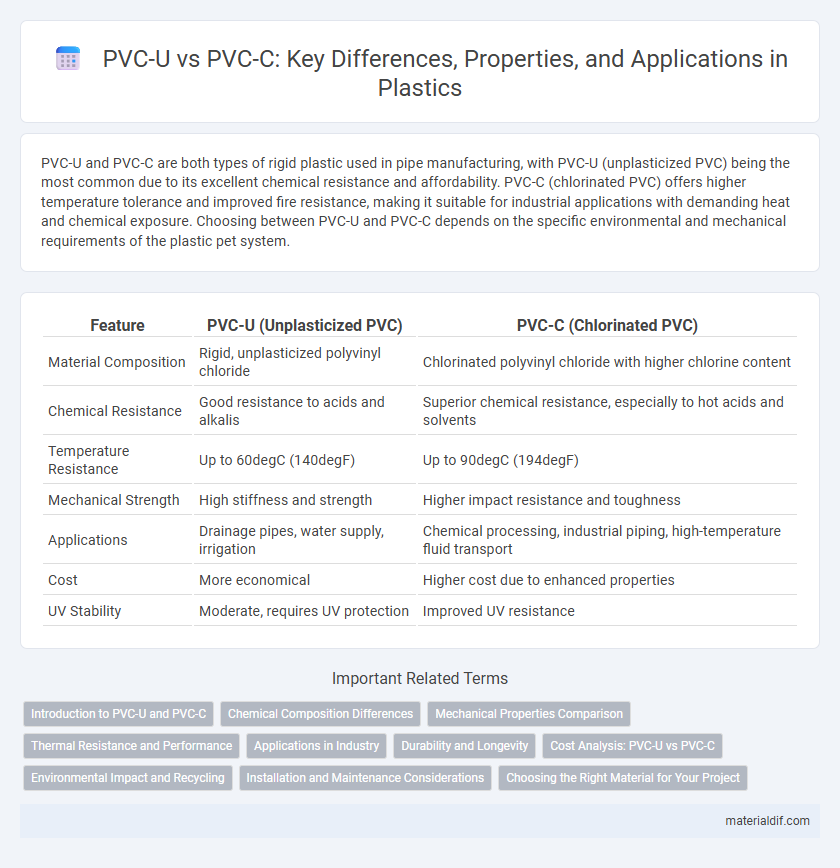

| Feature | PVC-U (Unplasticized PVC) | PVC-C (Chlorinated PVC) |

|---|---|---|

| Material Composition | Rigid, unplasticized polyvinyl chloride | Chlorinated polyvinyl chloride with higher chlorine content |

| Chemical Resistance | Good resistance to acids and alkalis | Superior chemical resistance, especially to hot acids and solvents |

| Temperature Resistance | Up to 60degC (140degF) | Up to 90degC (194degF) |

| Mechanical Strength | High stiffness and strength | Higher impact resistance and toughness |

| Applications | Drainage pipes, water supply, irrigation | Chemical processing, industrial piping, high-temperature fluid transport |

| Cost | More economical | Higher cost due to enhanced properties |

| UV Stability | Moderate, requires UV protection | Improved UV resistance |

Introduction to PVC-U and PVC-C

PVC-U (unplasticized polyvinyl chloride) offers high rigidity and chemical resistance, making it ideal for construction and piping applications requiring durability and long service life. PVC-C (chlorinated polyvinyl chloride) provides enhanced thermal stability and superior resistance to high temperatures and corrosive environments, often used in industrial fluid handling systems. Both materials are essential in plastic engineering, with PVC-U favored for general plumbing and PVC-C preferred in demanding chemical processing situations.

Chemical Composition Differences

PVC-U (unplasticized polyvinyl chloride) consists primarily of vinyl chloride monomers polymerized without added plasticizers, resulting in a rigid, durable material with high chemical resistance. PVC-C (chlorinated polyvinyl chloride) undergoes an additional chlorination process that increases its chlorine content from about 56% to approximately 67%, enhancing its thermal stability and chemical resistance, particularly against acids and bases. The increased chlorine content in PVC-C modifies its molecular structure, providing superior performance in harsh chemical environments compared to standard PVC-U.

Mechanical Properties Comparison

PVC-U exhibits superior tensile strength and stiffness compared to PVC-C, making it ideal for applications requiring high mechanical load resistance. PVC-C offers enhanced impact resistance and greater thermal stability, which improves its performance under cyclic loading and elevated temperature conditions. The chemical structure of PVC-C results in increased ductility, allowing better deformation before failure compared to the more brittle PVC-U.

Thermal Resistance and Performance

PVC-C (chlorinated polyvinyl chloride) exhibits superior thermal resistance compared to PVC-U (unplasticized polyvinyl chloride), sustaining continuous service temperatures up to 93degC versus PVC-U's limit around 60degC. This enhanced heat tolerance makes PVC-C ideal for industrial applications involving hot water or chemicals, where thermal performance and durability are critical. PVC-U remains widely used for cold water piping and drainage systems due to its cost-effectiveness and adequate performance below its thermal threshold.

Applications in Industry

PVC-U (unplasticized polyvinyl chloride) is widely used in construction for piping systems, window frames, and electric cable insulation due to its excellent chemical resistance and durability. PVC-C (chlorinated polyvinyl chloride) offers superior heat resistance and chemical stability, making it ideal for industrial applications such as chemical processing, hot water distribution, and manufacturing of corrosion-resistant valves and fittings. Industries requiring high-temperature and aggressive chemical environments prefer PVC-C over PVC-U for enhanced long-term performance and safety.

Durability and Longevity

PVC-U (unplasticized polyvinyl chloride) exhibits superior durability and longevity due to its rigid structure and resistance to chemical corrosion, making it ideal for plumbing and construction applications. PVC-C (chlorinated polyvinyl chloride) enhances heat resistance, allowing it to withstand higher temperatures without deforming, which extends its service life in industrial settings. Both materials are corrosion-resistant, but PVC-C offers greater thermal stability, resulting in longer lifespan under high-temperature conditions.

Cost Analysis: PVC-U vs PVC-C

PVC-U typically offers lower initial material costs compared to PVC-C, making it a more budget-friendly option for standard plumbing and drainage applications. PVC-C, however, provides enhanced chemical resistance and temperature tolerance, justifying its higher price in industrial and high-temperature environments. When conducting a cost analysis, the long-term savings from durability and reduced maintenance in PVC-C installations often balance out the upfront expense difference.

Environmental Impact and Recycling

PVC-U (unplasticized polyvinyl chloride) is widely preferred over PVC-C (chlorinated polyvinyl chloride) for its lower environmental impact due to easier recyclability and lower energy consumption during production. PVC-U recycling processes are more established, allowing for higher recovery rates and reduced landfill waste, whereas PVC-C's chlorinated composition complicates recycling and increases toxic emissions when incinerated. Selecting PVC-U is more sustainable in construction and manufacturing applications, aligning with eco-friendly practices and circular economy principles.

Installation and Maintenance Considerations

PVC-U (unplasticized polyvinyl chloride) offers easier installation due to its lightweight nature and compatibility with solvent cement joining, reducing labor time and costs. PVC-C (chlorinated polyvinyl chloride) requires heat fusion for joining, demanding specialized equipment and skilled labor, but delivers superior chemical resistance and durability, minimizing long-term maintenance needs. Maintenance of PVC-U involves routine inspection for UV degradation and chemical exposure, while PVC-C requires less frequent maintenance due to its enhanced thermal and chemical resilience.

Choosing the Right Material for Your Project

PVC-U (unplasticized polyvinyl chloride) offers superior chemical resistance and durability, making it ideal for cold water piping and general use in construction. PVC-C (chlorinated polyvinyl chloride) provides enhanced heat resistance and strength, suitable for hot water systems and industrial applications requiring higher temperatures. Selecting PVC-U or PVC-C depends on project-specific factors such as temperature range, chemical exposure, and mechanical stress to ensure long-term performance and cost efficiency.

PVC-U vs PVC-C Infographic

materialdif.com

materialdif.com