Plastic materials exhibit varying degrees of brittleness and toughness, which determine their performance under stress and impact. Brittleness refers to a material's tendency to fracture or break without significant deformation when subjected to force, often seen in rigid plastics like polystyrene. Toughness measures a plastic's ability to absorb energy and plastically deform without cracking, making materials like polyethylene ideal for applications requiring durability and impact resistance.

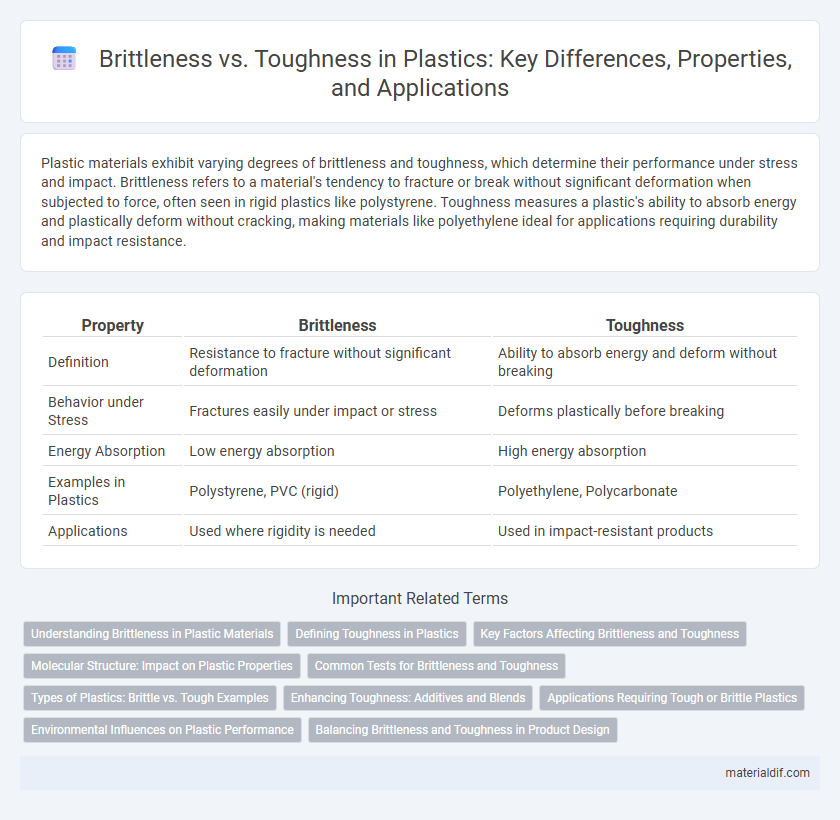

Table of Comparison

| Property | Brittleness | Toughness |

|---|---|---|

| Definition | Resistance to fracture without significant deformation | Ability to absorb energy and deform without breaking |

| Behavior under Stress | Fractures easily under impact or stress | Deforms plastically before breaking |

| Energy Absorption | Low energy absorption | High energy absorption |

| Examples in Plastics | Polystyrene, PVC (rigid) | Polyethylene, Polycarbonate |

| Applications | Used where rigidity is needed | Used in impact-resistant products |

Understanding Brittleness in Plastic Materials

Brittleness in plastic materials refers to their tendency to fracture or break without significant deformation when subjected to stress. It is a critical property influencing the failure mode of polymers, especially in applications requiring impact resistance or flexibility. Materials like polystyrene exhibit high brittleness, whereas polymers such as polyethylene demonstrate greater toughness due to their molecular structure and ability to absorb energy before fracturing.

Defining Toughness in Plastics

Toughness in plastics refers to the material's ability to absorb energy and deform plastically without fracturing, indicating its resistance to impact and mechanical stress. Unlike brittleness, which characterizes plastics that fracture easily under stress, toughness combines strength and ductility, enabling materials like polyethylene and polycarbonate to withstand sudden forces. Measuring toughness involves evaluating the area under the stress-strain curve during tensile testing, providing critical insights for selecting plastics in applications requiring durability and impact resistance.

Key Factors Affecting Brittleness and Toughness

Key factors affecting brittleness and toughness in plastics include molecular structure, temperature, and strain rate. High crystallinity and low molecular weight often increase brittleness, while amorphous polymers with higher molecular weight enhance toughness. Environmental conditions such as low temperature and high strain rates also tend to promote brittle behavior in plastic materials.

Molecular Structure: Impact on Plastic Properties

The molecular structure of plastics significantly influences their brittleness and toughness, where tightly packed polymer chains with strong intermolecular forces tend to increase brittleness by limiting chain mobility. In contrast, plastics with flexible, long-chain polymers and fewer cross-links exhibit greater toughness, allowing them to absorb impact without fracturing. The degree of crystallinity and the presence of additives also modify these mechanical properties by altering the polymer's molecular arrangement and energy dissipation capacity.

Common Tests for Brittleness and Toughness

Common tests for brittleness and toughness in plastics include the Izod impact test and Charpy impact test, which measure resistance to sudden impacts. The tensile test evaluates elongation and stress at break, providing data on material toughness and brittleness. Flexural and fatigue tests further assess the plastic's ability to withstand repeated or bending stresses.

Types of Plastics: Brittle vs. Tough Examples

Polycarbonate and polyethylene are prime examples of tough plastics, offering high impact resistance and flexibility, making them ideal for protective gear and containers. In contrast, polystyrene and acrylic are more brittle, prone to cracking under stress, which limits their use to applications like disposable cutlery and display cases. Understanding the brittleness vs toughness of these plastics helps in selecting the right material for durability and performance requirements.

Enhancing Toughness: Additives and Blends

Enhancing toughness in plastics involves incorporating additives such as impact modifiers, plasticizers, and rubber particles which improve energy absorption and reduce brittleness. Blending polymers like polyethylene with toughening agents creates materials that resist cracking under stress while maintaining flexibility. These modifications optimize mechanical performance, making plastics suitable for demanding applications where durability is critical.

Applications Requiring Tough or Brittle Plastics

Applications requiring toughness in plastics often include automotive parts, protective gear, and industrial components where high impact resistance and durability are essential. Brittle plastics find usage in optical devices, electronic housings, and precision instruments where dimensional stability and rigidity are prioritized over flexibility. Selecting the appropriate plastic based on brittleness versus toughness ensures optimal performance and longevity in specific engineering and manufacturing contexts.

Environmental Influences on Plastic Performance

Environmental factors such as temperature, UV radiation, and chemical exposure significantly impact the brittleness and toughness of plastics. Low temperatures can increase plastic brittleness by reducing molecular mobility, while prolonged UV exposure causes polymer chain degradation, leading to embrittlement. Chemical exposure, including solvents and moisture, can alter plastic microstructure and mechanical properties, decreasing toughness and accelerating failure.

Balancing Brittleness and Toughness in Product Design

Balancing brittleness and toughness in plastic product design requires selecting materials with optimized molecular structures to enhance impact resistance without sacrificing strength. Incorporating additives such as plasticizers or reinforcing fillers often improves toughness while mitigating the risk of fracture under stress. Design decisions must consider environmental factors like temperature and load conditions to achieve an ideal compromise between durability and flexibility.

Brittleness vs Toughness Infographic

materialdif.com

materialdif.com