PET (Polyethylene Terephthalate) offers excellent clarity, good chemical resistance, and is widely used for beverage containers and packaging due to its lightweight and recyclability. PBT (Polybutylene Terephthalate) features higher heat resistance, superior electrical insulation properties, and better dimensional stability, making it ideal for automotive parts and electrical components. Choosing between PET and PBT depends on the application requirements, balancing factors like mechanical strength, thermal stability, and environmental impact.

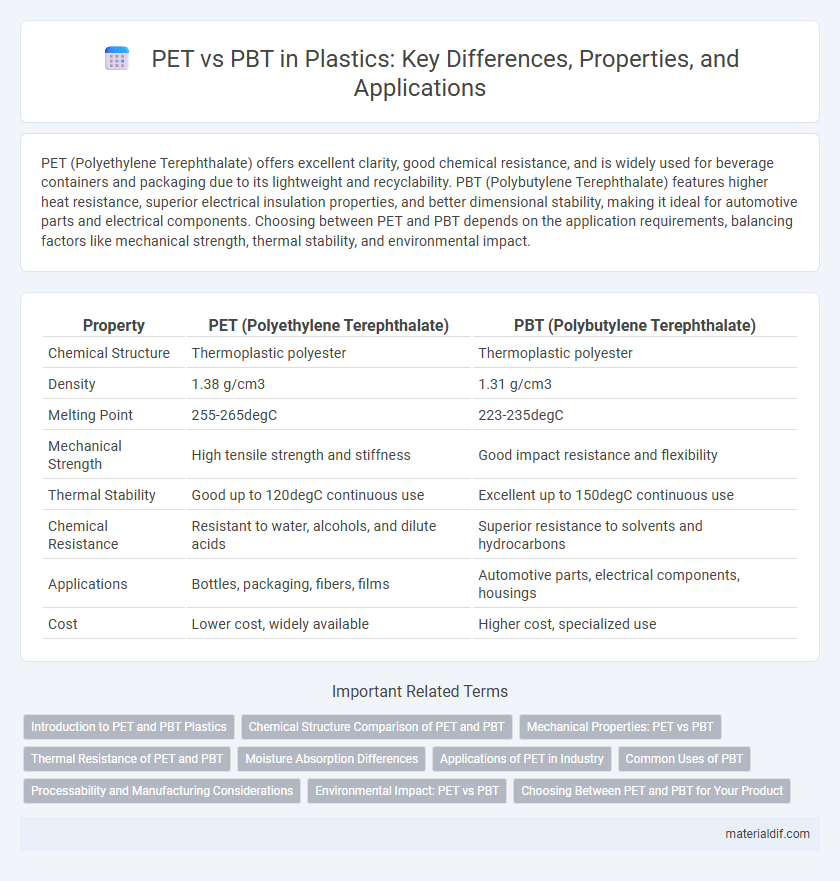

Table of Comparison

| Property | PET (Polyethylene Terephthalate) | PBT (Polybutylene Terephthalate) |

|---|---|---|

| Chemical Structure | Thermoplastic polyester | Thermoplastic polyester |

| Density | 1.38 g/cm3 | 1.31 g/cm3 |

| Melting Point | 255-265degC | 223-235degC |

| Mechanical Strength | High tensile strength and stiffness | Good impact resistance and flexibility |

| Thermal Stability | Good up to 120degC continuous use | Excellent up to 150degC continuous use |

| Chemical Resistance | Resistant to water, alcohols, and dilute acids | Superior resistance to solvents and hydrocarbons |

| Applications | Bottles, packaging, fibers, films | Automotive parts, electrical components, housings |

| Cost | Lower cost, widely available | Higher cost, specialized use |

Introduction to PET and PBT Plastics

Polyethylene terephthalate (PET) and polybutylene terephthalate (PBT) are two widely used thermoplastic polymers belonging to the polyester family, known for their excellent mechanical properties and chemical resistance. PET is commonly utilized in packaging, textiles, and beverage bottles due to its clarity, strength, and recyclability, while PBT finds applications in automotive parts, electrical components, and industrial machinery because of its superior dimensional stability and resistance to heat and chemicals. Both plastics are engineered for durability but cater to distinct industries based on their thermal and physical characteristics.

Chemical Structure Comparison of PET and PBT

PET (Polyethylene Terephthalate) and PBT (Polybutylene Terephthalate) both belong to the polyester family, sharing a similar aromatic ring structure derived from terephthalic acid. The key chemical difference lies in their glycol components: PET contains ethylene glycol units with two carbon atoms, while PBT incorporates butylene glycol units with four carbon atoms, influencing their molecular flexibility and crystallization rates. This variation in the aliphatic diol segment results in PBT having improved impact resistance and faster crystallization compared to PET, affecting their performance in applications requiring thermal and mechanical durability.

Mechanical Properties: PET vs PBT

PET (Polyethylene Terephthalate) exhibits high tensile strength and stiffness, making it suitable for structural components requiring durability. PBT (Polybutylene Terephthalate) offers superior impact resistance and dimensional stability, ideal for applications subject to mechanical stress and thermal cycling. The choice between PET and PBT depends on specific mechanical property requirements such as toughness versus rigidity.

Thermal Resistance of PET and PBT

PET (Polyethylene Terephthalate) exhibits a thermal resistance typically up to 120degC, making it suitable for applications requiring moderate heat tolerance. PBT (Polybutylene Terephthalate) offers enhanced thermal resistance, withstanding temperatures around 150degC, which suits it for higher temperature environments and improved dimensional stability under heat stress. The superior thermal endurance of PBT over PET makes it preferable in automotive and electrical components exposed to elevated temperatures.

Moisture Absorption Differences

PET (Polyethylene Terephthalate) exhibits higher moisture absorption rates compared to PBT (Polybutylene Terephthalate), typically absorbing around 0.4-0.8% moisture at equilibrium, whereas PBT absorbs significantly less, usually below 0.4%. This difference impacts the dimensional stability and mechanical properties of the materials, with PBT showing better performance in moist or humid environments. Industries often prefer PBT for applications requiring low moisture uptake and enhanced electrical insulation.

Applications of PET in Industry

PET, or polyethylene terephthalate, is widely used in industry for packaging, especially in beverage bottles, food containers, and pharmaceutical packaging due to its strength, transparency, and recyclability. Its excellent chemical resistance and barrier properties make it suitable for cosmetic containers and microwaveable food trays. PET's versatility and cost-effectiveness drive its application across diverse sectors such as automotive, electronics, and textiles.

Common Uses of PBT

Polybutylene terephthalate (PBT) is widely used in automotive components, electrical connectors, and household appliances due to its high strength, chemical resistance, and thermal stability. Unlike polyethylene terephthalate (PET), PBT exhibits superior dimensional stability and electrical insulation properties, making it ideal for precision-engineered parts such as gears, switches, and circuit boards. PBT's resistance to moisture and abrasion also enhances its application in outdoor and industrial environments.

Processability and Manufacturing Considerations

PET offers excellent processability with high melting temperature around 250degC, allowing efficient injection molding and extrusion while maintaining dimensional stability and clarity. PBT, with a slightly lower melting point near 223degC, enables faster cycle times and improved flow characteristics, reducing defects in complex mold geometries. Manufacturing considerations favor PET for applications demanding superior mechanical strength and chemical resistance, whereas PBT excels in processes requiring enhanced electrical insulation and flexibility.

Environmental Impact: PET vs PBT

PET (Polyethylene Terephthalate) demonstrates a lower environmental impact compared to PBT (Polybutylene Terephthalate) due to its higher recyclability rate and widespread recycling infrastructure. PET's production typically generates fewer greenhouse gas emissions and consumes less energy than PBT manufacturing processes. Moreover, PET's biodegradability in certain conditions contributes to reduced long-term environmental pollution relative to the more chemically resistant PBT.

Choosing Between PET and PBT for Your Product

PET offers excellent clarity and chemical resistance, making it ideal for packaging applications requiring transparency and toughness. PBT provides superior dimensional stability and heat resistance, suited for automotive and electrical components subjected to high temperatures. Selecting between PET and PBT depends on the product's need for optical clarity versus thermal and mechanical durability.

PET vs PBT Infographic

materialdif.com

materialdif.com