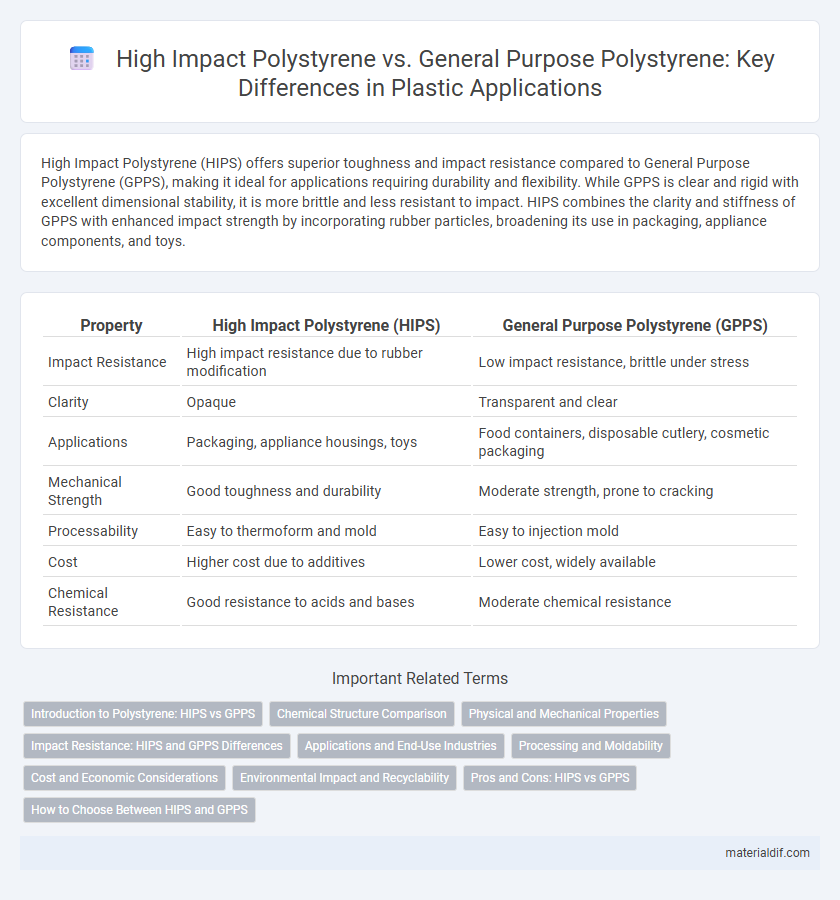

High Impact Polystyrene (HIPS) offers superior toughness and impact resistance compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring durability and flexibility. While GPPS is clear and rigid with excellent dimensional stability, it is more brittle and less resistant to impact. HIPS combines the clarity and stiffness of GPPS with enhanced impact strength by incorporating rubber particles, broadening its use in packaging, appliance components, and toys.

Table of Comparison

| Property | High Impact Polystyrene (HIPS) | General Purpose Polystyrene (GPPS) |

|---|---|---|

| Impact Resistance | High impact resistance due to rubber modification | Low impact resistance, brittle under stress |

| Clarity | Opaque | Transparent and clear |

| Applications | Packaging, appliance housings, toys | Food containers, disposable cutlery, cosmetic packaging |

| Mechanical Strength | Good toughness and durability | Moderate strength, prone to cracking |

| Processability | Easy to thermoform and mold | Easy to injection mold |

| Cost | Higher cost due to additives | Lower cost, widely available |

| Chemical Resistance | Good resistance to acids and bases | Moderate chemical resistance |

Introduction to Polystyrene: HIPS vs GPPS

High Impact Polystyrene (HIPS) offers enhanced toughness and impact resistance compared to General Purpose Polystyrene (GPPS), which is more brittle and less durable. HIPS contains rubber modifiers that improve flexibility and prevent cracking, making it ideal for packaging, toys, and appliance components. GPPS is favored for its clarity and rigidity, commonly used in clear containers, disposable cutlery, and laboratory ware where transparency is essential.

Chemical Structure Comparison

High Impact Polystyrene (HIPS) incorporates polybutadiene rubber into the polystyrene matrix, creating a two-phase system that enhances toughness and impact resistance compared to General Purpose Polystyrene (GPPS), which is a rigid, brittle polymer consisting solely of polystyrene chains. The rubber domains in HIPS disrupt the uniformity of the styrene polymer chains in GPPS, providing superior energy absorption upon impact. This structural modification significantly alters mechanical properties while maintaining similar chemical composition elements, primarily carbon and hydrogen atoms arranged in styrene monomer units.

Physical and Mechanical Properties

High Impact Polystyrene (HIPS) exhibits superior impact resistance and greater toughness compared to General Purpose Polystyrene (GPPS), making it suitable for applications requiring enhanced durability. HIPS typically has a tensile strength of around 3,800 psi and an elongation at break up to 50%, whereas GPPS shows higher stiffness but is more brittle, with tensile strength approximately 5,000 psi and elongation below 3%. The improved mechanical properties of HIPS result from rubber modifiers dispersed within the polymer matrix, providing better resistance to deformation and fracture.

Impact Resistance: HIPS and GPPS Differences

High Impact Polystyrene (HIPS) is engineered with added rubber particles, significantly enhancing its impact resistance compared to General Purpose Polystyrene (GPPS), which is more rigid but brittle. HIPS exhibits superior toughness and durability under mechanical stress, making it ideal for applications requiring enhanced shock absorption and flexibility. GPPS offers clarity and stiffness but lacks the impact strength needed for demanding environments, resulting in higher susceptibility to cracking or breaking.

Applications and End-Use Industries

High Impact Polystyrene (HIPS) is widely used in consumer products, packaging, and appliance housings due to its enhanced toughness and impact resistance compared to General Purpose Polystyrene (GPPS). GPPS is typically found in applications requiring clarity and rigidity, such as food containers, laboratory ware, and CD cases, benefiting from its excellent gloss and transparency. End-use industries for HIPS include automotive, electronics, and packaging, while GPPS serves prominently in food service, healthcare, and consumer goods sectors.

Processing and Moldability

High Impact Polystyrene (HIPS) exhibits superior moldability and processing versatility compared to General Purpose Polystyrene (GPPS) due to its rubber-modified polymer matrix, which enhances impact resistance and flexibility during injection molding. HIPS allows for more intricate and durable shapes with reduced brittleness, making it suitable for complex and high-stress applications. GPPS, while easier to process with smoother surface finishes, tends to be more brittle and less suitable for parts requiring high impact strength or detailed molding.

Cost and Economic Considerations

High Impact Polystyrene (HIPS) costs more than General Purpose Polystyrene (GPPS) due to its enhanced impact resistance and durability, making it suitable for applications requiring strength and longevity. GPPS is more economical for products with low mechanical stress, offering a cost-effective solution for clear, rigid packaging and disposable items. The choice between HIPS and GPPS depends on balancing upfront material expenses against long-term performance and product lifespan.

Environmental Impact and Recyclability

High Impact Polystyrene (HIPS) offers improved strength and durability compared to General Purpose Polystyrene (GPPS), but both materials pose significant environmental challenges due to their non-biodegradable nature and limited recycling infrastructure. HIPS contains rubber modifiers that complicate recycling processes, resulting in lower recyclability rates compared to GPPS, which is more readily accepted by standard recycling facilities. Efforts to enhance the recyclability of HIPS focus on developing specialized recycling streams, while GPPS recycling programs benefit from established collection and processing systems, reducing landfill waste and environmental pollution.

Pros and Cons: HIPS vs GPPS

High Impact Polystyrene (HIPS) offers superior impact resistance and increased durability compared to General Purpose Polystyrene (GPPS), making it ideal for applications requiring toughness and rigidity. GPPS provides better clarity and a smoother surface finish, which benefits packaging and display uses but lacks the strength and impact resistance found in HIPS. The main trade-off involves choosing HIPS for enhanced mechanical properties and GPPS for optical clarity and cost-effectiveness in less demanding environments.

How to Choose Between HIPS and GPPS

Choosing between High Impact Polystyrene (HIPS) and General Purpose Polystyrene (GPPS) depends on the required durability and application. HIPS offers enhanced impact resistance, making it ideal for packaging, appliance housings, and toys, while GPPS provides better clarity and stiffness for displays and food containers. Evaluating factors such as mechanical strength, transparency needs, and cost-effectiveness ensures optimal material selection for specific industry demands.

High Impact Polystyrene vs General Purpose Polystyrene Infographic

materialdif.com

materialdif.com