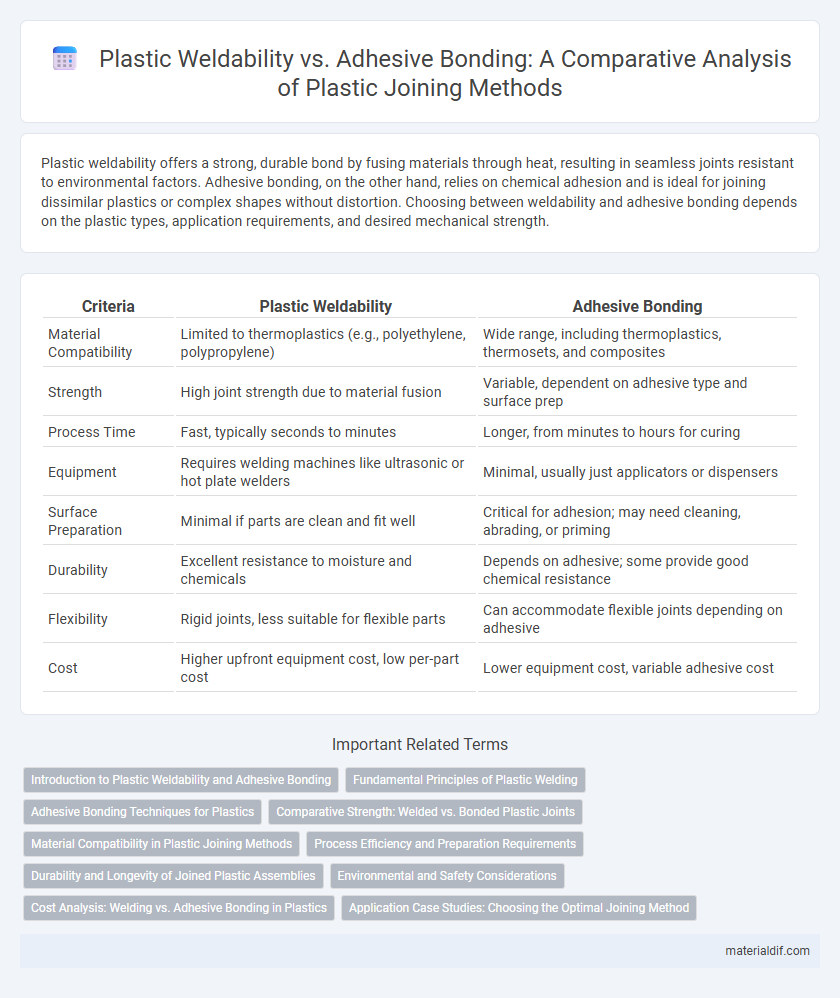

Plastic weldability offers a strong, durable bond by fusing materials through heat, resulting in seamless joints resistant to environmental factors. Adhesive bonding, on the other hand, relies on chemical adhesion and is ideal for joining dissimilar plastics or complex shapes without distortion. Choosing between weldability and adhesive bonding depends on the plastic types, application requirements, and desired mechanical strength.

Table of Comparison

| Criteria | Plastic Weldability | Adhesive Bonding |

|---|---|---|

| Material Compatibility | Limited to thermoplastics (e.g., polyethylene, polypropylene) | Wide range, including thermoplastics, thermosets, and composites |

| Strength | High joint strength due to material fusion | Variable, dependent on adhesive type and surface prep |

| Process Time | Fast, typically seconds to minutes | Longer, from minutes to hours for curing |

| Equipment | Requires welding machines like ultrasonic or hot plate welders | Minimal, usually just applicators or dispensers |

| Surface Preparation | Minimal if parts are clean and fit well | Critical for adhesion; may need cleaning, abrading, or priming |

| Durability | Excellent resistance to moisture and chemicals | Depends on adhesive; some provide good chemical resistance |

| Flexibility | Rigid joints, less suitable for flexible parts | Can accommodate flexible joints depending on adhesive |

| Cost | Higher upfront equipment cost, low per-part cost | Lower equipment cost, variable adhesive cost |

Introduction to Plastic Weldability and Adhesive Bonding

Plastic weldability depends on the material's thermoplastic properties, allowing surfaces to be fused through heat, pressure, or ultrasonic energy, creating strong, homogeneous joints. Adhesive bonding relies on chemical reactions between adhesives and plastic surfaces, forming a durable interface suited for dissimilar materials and complex geometries. Understanding plastic types such as polyethylene, polypropylene, and polycarbonate is crucial for selecting appropriate welding or bonding methods to optimize joint strength and performance.

Fundamental Principles of Plastic Welding

Plastic welding relies on the fundamental principle of melting and fusing polymer surfaces through heat, pressure, or ultrasonic vibrations to create a strong, continuous joint. This process exploits the thermoplastic properties of materials, allowing molecular chains to interdiffuse and re-solidify into a homogenous bond. Unlike adhesive bonding, which depends on interfacial adhesion and curing agents, plastic welding produces joints with enhanced mechanical strength and chemical resistance by directly merging polymer matrices.

Adhesive Bonding Techniques for Plastics

Adhesive bonding techniques for plastics involve using specialized adhesives such as epoxy, polyurethane, and cyanoacrylate to create strong, durable joints without compromising material integrity. Surface preparation methods like plasma treatment, corona discharge, or chemical etching enhance bond strength by improving adhesive wettability and mechanical interlocking. This technique allows for bonding dissimilar polymers and complex geometries, providing versatile solutions in automotive, electronics, and medical device manufacturing.

Comparative Strength: Welded vs. Bonded Plastic Joints

Welded plastic joints typically exhibit higher tensile and shear strength compared to adhesive-bonded joints due to the fusion of polymer molecules creating a homogeneous material interface. Adhesive bonds rely on surface interaction and can be weaker under dynamic or thermal stresses, whereas welding ensures a continuous molecular structure that enhances durability. Material compatibility, joint design, and environmental exposure significantly influence the comparative strength outcomes between welded and bonded plastic assemblies.

Material Compatibility in Plastic Joining Methods

Plastic weldability depends heavily on the thermoplastic nature of the materials, allowing molecular fusion under heat and pressure, which is optimal for compatible polymers such as polyethylene and polypropylene. Adhesive bonding offers broader material compatibility, including dissimilar plastics like polycarbonate to ABS, by using specialized adhesives that cater to surface energy and chemical composition. Selecting the appropriate plastic joining method requires understanding the polymer type, surface treatment, and environmental resistance to ensure strong, durable bonds.

Process Efficiency and Preparation Requirements

Plastic weldability offers superior process efficiency by creating strong, permanent joints quickly with minimal surface preparation, often requiring only clean, compatible materials and controlled heat or ultrasonic energy application. Adhesive bonding demands extensive surface treatment such as cleaning, sanding, and priming to ensure proper adhesion, which increases preparation time and complexity. Welded joints typically provide higher strength and repeatability in automated processes compared to the longer curing times and potential variability associated with adhesives.

Durability and Longevity of Joined Plastic Assemblies

Plastic weldability offers superior durability and longevity compared to adhesive bonding by creating a fused joint that behaves like a single piece of material, ensuring high resistance to mechanical stresses and environmental factors. Welded plastic assemblies often exhibit greater strength retention under cyclic loading and exposure to moisture, chemicals, and temperature variations. Adhesive bonds, while versatile, tend to degrade over time due to adhesive layer delamination and environmental sensitivity, limiting the lifespan of the joined plastic components.

Environmental and Safety Considerations

Plastic weldability offers a more environmentally friendly option compared to adhesive bonding by eliminating the need for solvents and reducing hazardous waste. Welding processes typically produce fewer volatile organic compounds (VOCs), enhancing workplace safety and minimizing air pollution. Adhesive bonding often relies on chemical agents that pose health risks and require careful disposal to prevent environmental contamination.

Cost Analysis: Welding vs. Adhesive Bonding in Plastics

Plastic welding typically incurs higher initial equipment costs but offers lower long-term expenses due to faster processing times and stronger, more durable joints. Adhesive bonding involves lower upfront investment but can lead to increased labor and material costs over time, especially for high-volume production requiring longer curing times. Overall, welding is often more cost-effective for large-scale or structural applications, while adhesive bonding suits smaller projects with minimal load demands.

Application Case Studies: Choosing the Optimal Joining Method

Plastic weldability offers strong, durable joints ideal for automotive fuel tanks and medical devices requiring leak-proof seals, while adhesive bonding excels in electronics and aerospace components needing flexible, vibration-resistant unions. Case studies reveal plastic welding provides faster processing and higher mechanical strength in thermoplastics, whereas adhesives allow joining of dissimilar materials and complex geometries. Optimal joining methods depend on factors like material compatibility, environmental exposure, load requirements, and production volume to maximize performance and cost-efficiency.

Plastic Weldability vs Adhesive Bonding Infographic

materialdif.com

materialdif.com