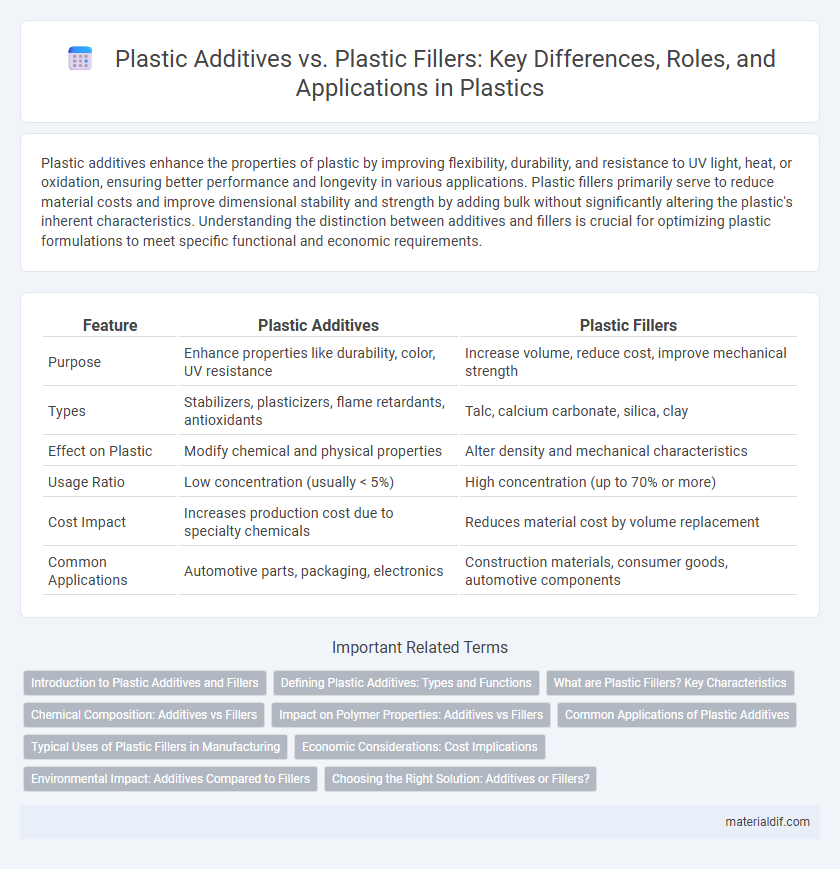

Plastic additives enhance the properties of plastic by improving flexibility, durability, and resistance to UV light, heat, or oxidation, ensuring better performance and longevity in various applications. Plastic fillers primarily serve to reduce material costs and improve dimensional stability and strength by adding bulk without significantly altering the plastic's inherent characteristics. Understanding the distinction between additives and fillers is crucial for optimizing plastic formulations to meet specific functional and economic requirements.

Table of Comparison

| Feature | Plastic Additives | Plastic Fillers |

|---|---|---|

| Purpose | Enhance properties like durability, color, UV resistance | Increase volume, reduce cost, improve mechanical strength |

| Types | Stabilizers, plasticizers, flame retardants, antioxidants | Talc, calcium carbonate, silica, clay |

| Effect on Plastic | Modify chemical and physical properties | Alter density and mechanical characteristics |

| Usage Ratio | Low concentration (usually < 5%) | High concentration (up to 70% or more) |

| Cost Impact | Increases production cost due to specialty chemicals | Reduces material cost by volume replacement |

| Common Applications | Automotive parts, packaging, electronics | Construction materials, consumer goods, automotive components |

Introduction to Plastic Additives and Fillers

Plastic additives are specialized compounds integrated into polymer matrices to enhance properties such as flexibility, durability, UV resistance, and flame retardancy, vital for customizing plastic performance in various industries. Plastic fillers, in contrast, are inert materials like calcium carbonate or talc that primarily improve mechanical strength, reduce cost, and modify density without significantly altering the chemical properties of the base polymer. Understanding the roles and selection criteria of additives versus fillers is essential for optimizing plastic formulation and achieving specific functional or economic objectives in manufacturing.

Defining Plastic Additives: Types and Functions

Plastic additives are chemical substances incorporated into polymers to enhance properties such as flexibility, durability, and UV resistance, including plasticizers, stabilizers, flame retardants, and colorants. These additives function to improve processability, extend product lifespan, and provide specific performance characteristics tailored to application needs. Unlike plastic fillers, which primarily increase volume and reduce cost, additives actively modify the physical and chemical behavior of plastic materials.

What are Plastic Fillers? Key Characteristics

Plastic fillers are inert materials added to polymers to enhance properties such as stiffness, dimensional stability, and cost-effectiveness without significantly altering the polymer's chemical nature. Common fillers include calcium carbonate, talc, and mica, which improve mechanical strength and reduce material costs while maintaining processability. These additives differ from plastic additives by primarily providing physical reinforcement rather than modifying chemical or thermal properties.

Chemical Composition: Additives vs Fillers

Plastic additives are primarily chemical compounds such as stabilizers, plasticizers, and flame retardants designed to enhance properties like flexibility, durability, and resistance to degradation. Plastic fillers, however, are typically inorganic materials like calcium carbonate, talc, or silica used to reduce cost, improve mechanical properties, and modify density without significantly altering the chemical structure of the base polymer. The chemical composition of additives involves active molecules that interact chemically with the polymer matrix, whereas fillers mainly serve as inert reinforcing agents with minimal chemical interaction.

Impact on Polymer Properties: Additives vs Fillers

Plastic additives significantly enhance polymer properties by improving flexibility, durability, and resistance to UV radiation and oxidation. Plastic fillers primarily influence mechanical strength, dimensional stability, and reduce material costs by increasing volume without substantially altering chemical properties. The choice between additives and fillers depends on desired enhancements, as additives modify polymer behavior at the molecular level, while fillers mainly provide physical reinforcement.

Common Applications of Plastic Additives

Plastic additives enhance the properties of polymers to meet specific performance requirements in industries such as automotive, packaging, and electronics. Common applications include UV stabilizers to protect against sunlight degradation, plasticizers to improve flexibility in PVC products, and flame retardants in electrical housings to meet safety standards. These additives enable manufacturers to tailor plastics for durability, aesthetics, and functionality across various commercial and consumer goods.

Typical Uses of Plastic Fillers in Manufacturing

Plastic fillers are commonly used in manufacturing to enhance the mechanical properties, reduce production costs, and improve dimensional stability of plastic products. Typical uses include reinforcing materials such as glass fibers, calcium carbonate, and talc, which increase strength and rigidity in automotive parts, construction materials, and packaging. These fillers also improve thermal conductivity and reduce shrinkage during molding processes.

Economic Considerations: Cost Implications

Plastic additives typically incur higher costs due to their specialized chemical formulations that enhance properties like durability, UV resistance, and flexibility, directly affecting the product's performance and longevity. Conversely, plastic fillers are more cost-effective, primarily used to reduce the overall material cost by replacing part of the base polymer without significantly improving performance. Manufacturers often balance additives and fillers based on budget constraints and required material specifications to optimize production expenses while maintaining product quality.

Environmental Impact: Additives Compared to Fillers

Plastic additives, such as plasticizers, stabilizers, and flame retardants, often contain toxic chemicals that can leach into the environment, posing significant ecological and health risks. Plastic fillers, typically inorganic materials like calcium carbonate or talc, generally have a lower environmental impact as they are less likely to release harmful substances but can increase the volume of non-biodegradable waste. Understanding the distinct environmental consequences of additives versus fillers is crucial for developing sustainable plastic formulations and reducing pollution.

Choosing the Right Solution: Additives or Fillers?

Plastic additives enhance properties such as flexibility, UV resistance, and flame retardancy, while plastic fillers primarily reduce cost and improve mechanical strength or thermal conductivity. Selecting the right solution depends on the desired performance criteria and application requirements, with additives suited for functional enhancements and fillers favored for structural support and economic efficiency. Understanding the specific needs of the plastic product ensures optimal integration of additives or fillers for improved quality and cost-effectiveness.

Plastic Additives vs Plastic Fillers Infographic

materialdif.com

materialdif.com