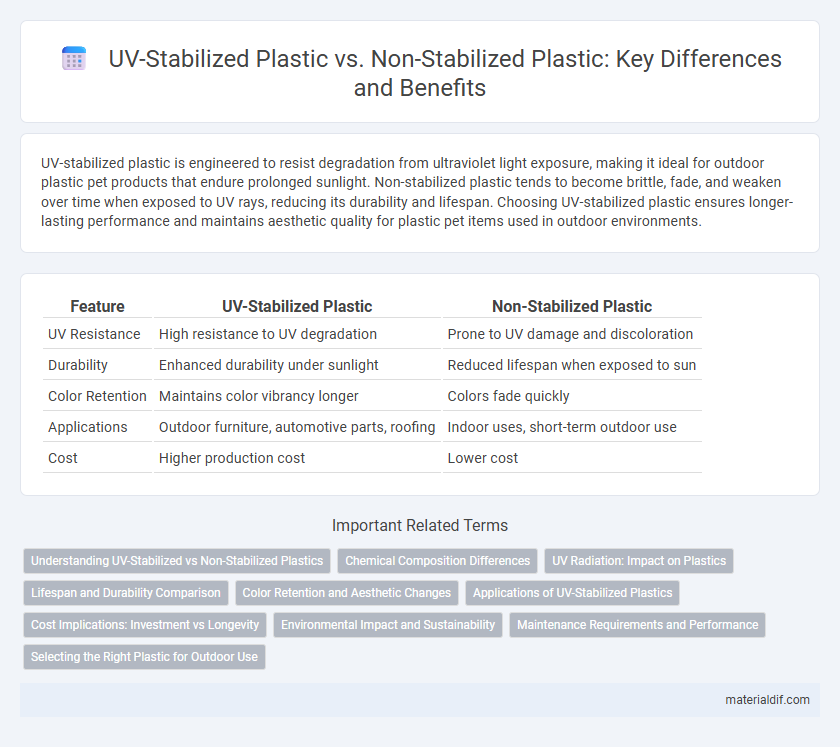

UV-stabilized plastic is engineered to resist degradation from ultraviolet light exposure, making it ideal for outdoor plastic pet products that endure prolonged sunlight. Non-stabilized plastic tends to become brittle, fade, and weaken over time when exposed to UV rays, reducing its durability and lifespan. Choosing UV-stabilized plastic ensures longer-lasting performance and maintains aesthetic quality for plastic pet items used in outdoor environments.

Table of Comparison

| Feature | UV-Stabilized Plastic | Non-Stabilized Plastic |

|---|---|---|

| UV Resistance | High resistance to UV degradation | Prone to UV damage and discoloration |

| Durability | Enhanced durability under sunlight | Reduced lifespan when exposed to sun |

| Color Retention | Maintains color vibrancy longer | Colors fade quickly |

| Applications | Outdoor furniture, automotive parts, roofing | Indoor uses, short-term outdoor use |

| Cost | Higher production cost | Lower cost |

Understanding UV-Stabilized vs Non-Stabilized Plastics

UV-stabilized plastics contain additives that absorb or block ultraviolet radiation, preventing degradation and extending their lifespan when exposed to sunlight. Non-stabilized plastics lack these protective additives, making them prone to discoloration, brittleness, and structural failure under prolonged UV exposure. Choosing UV-stabilized plastics is critical for outdoor applications requiring durability and resistance to environmental elements.

Chemical Composition Differences

UV-stabilized plastic contains specific additives such as UV absorbers, hindered amine light stabilizers (HALS), and antioxidants that protect polymer chains from degradation caused by ultraviolet radiation. Non-stabilized plastic lacks these chemical compounds, making it more prone to photo-oxidative damage, discoloration, and brittleness under prolonged sun exposure. The presence of UV stabilizers enhances the chemical resilience of plastics by interrupting free radical formation and minimizing polymer chain scission.

UV Radiation: Impact on Plastics

UV-stabilized plastic contains additives that absorb or block ultraviolet radiation, preventing polymer chain degradation and extending material lifespan. Non-stabilized plastic exposed to UV radiation undergoes photodegradation, resulting in discoloration, brittleness, and reduced mechanical strength. Effective UV stabilization is critical for outdoor applications to maintain plastic integrity and performance under prolonged sun exposure.

Lifespan and Durability Comparison

UV-stabilized plastic significantly extends the lifespan and durability of products by resisting degradation caused by ultraviolet radiation, maintaining structural integrity and color consistency over time. Non-stabilized plastic, exposed to prolonged UV light, typically suffers from brittleness, surface cracking, and discoloration, leading to a shorter functional lifespan. The integration of UV stabilizers enhances resistance to environmental stressors, making UV-stabilized plastics ideal for outdoor applications where long-term performance is critical.

Color Retention and Aesthetic Changes

UV-stabilized plastic incorporates additives that protect against ultraviolet radiation, significantly enhancing color retention and minimizing aesthetic changes over time compared to non-stabilized plastic. Non-stabilized plastic is prone to fading, yellowing, and surface degradation when exposed to sunlight, leading to noticeable color loss and compromised appearance. Choosing UV-stabilized plastic ensures prolonged vibrancy and durability for outdoor applications where visual integrity is critical.

Applications of UV-Stabilized Plastics

UV-stabilized plastics are extensively used in outdoor applications such as automotive parts, roofing materials, and agricultural films where prolonged exposure to sunlight causes degradation in non-stabilized plastics. These materials exhibit enhanced resistance to ultraviolet radiation, preventing discoloration, cracking, and loss of mechanical properties. This makes UV-stabilized plastics crucial for construction, outdoor furniture, and packaging industries requiring durability and long-term performance under harsh environmental conditions.

Cost Implications: Investment vs Longevity

UV-stabilized plastic incurs higher initial costs due to advanced additives that protect against sun damage, significantly extending the material's lifespan. Non-stabilized plastic, while cheaper upfront, often requires more frequent replacement and maintenance because it degrades quickly under UV exposure. Evaluating cost implications reveals that investing in UV-stabilized plastic reduces long-term expenses by minimizing deterioration and preserving structural integrity.

Environmental Impact and Sustainability

UV-stabilized plastic significantly reduces degradation caused by ultraviolet radiation, extending product lifespan and minimizing plastic waste accumulation in the environment. Non-stabilized plastic breaks down faster under UV exposure, leading to microplastic pollution and higher environmental toxicity. Choosing UV-stabilized plastics enhances sustainability by lowering the frequency of replacements and reducing harmful ecological impacts associated with plastic deterioration.

Maintenance Requirements and Performance

UV-stabilized plastic offers superior resistance to sunlight-induced degradation, significantly reducing the need for frequent maintenance compared to non-stabilized plastic, which tends to become brittle and discolored over time. This enhanced durability ensures longer performance life in outdoor applications, minimizing repair and replacement costs. Non-stabilized plastic requires regular inspections and protective coatings to maintain usability, whereas UV-stabilized variants maintain structural integrity and appearance with minimal upkeep.

Selecting the Right Plastic for Outdoor Use

UV-stabilized plastic is engineered with additives that absorb or block ultraviolet radiation, significantly enhancing its resistance to sun-induced degradation and prolonging its lifespan in outdoor environments. In contrast, non-stabilized plastic tends to become brittle, fade, and crack when exposed to prolonged UV exposure, making it unsuitable for long-term outdoor applications. Selecting UV-stabilized plastic is crucial for outdoor furniture, piping, and construction materials to ensure durability, maintain structural integrity, and reduce maintenance costs.

UV-Stabilized Plastic vs Non-Stabilized Plastic Infographic

materialdif.com

materialdif.com