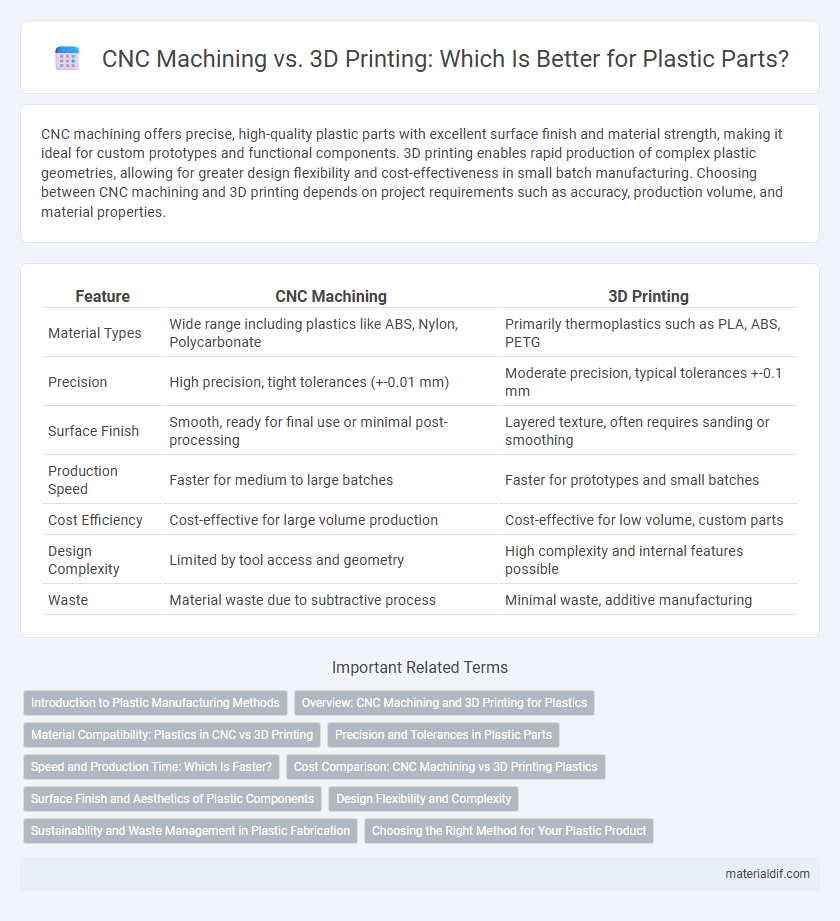

CNC machining offers precise, high-quality plastic parts with excellent surface finish and material strength, making it ideal for custom prototypes and functional components. 3D printing enables rapid production of complex plastic geometries, allowing for greater design flexibility and cost-effectiveness in small batch manufacturing. Choosing between CNC machining and 3D printing depends on project requirements such as accuracy, production volume, and material properties.

Table of Comparison

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Material Types | Wide range including plastics like ABS, Nylon, Polycarbonate | Primarily thermoplastics such as PLA, ABS, PETG |

| Precision | High precision, tight tolerances (+-0.01 mm) | Moderate precision, typical tolerances +-0.1 mm |

| Surface Finish | Smooth, ready for final use or minimal post-processing | Layered texture, often requires sanding or smoothing |

| Production Speed | Faster for medium to large batches | Faster for prototypes and small batches |

| Cost Efficiency | Cost-effective for large volume production | Cost-effective for low volume, custom parts |

| Design Complexity | Limited by tool access and geometry | High complexity and internal features possible |

| Waste | Material waste due to subtractive process | Minimal waste, additive manufacturing |

Introduction to Plastic Manufacturing Methods

CNC machining and 3D printing are prominent plastic manufacturing methods, each offering unique advantages for producing precise components. CNC machining uses subtractive processes to shape plastic blocks with high accuracy, ideal for complex geometries and durable parts. In contrast, 3D printing builds plastic parts layer-by-layer through additive manufacturing, enabling rapid prototyping and customization with materials like ABS, PLA, and nylon.

Overview: CNC Machining and 3D Printing for Plastics

CNC machining for plastics involves subtractive manufacturing where material is precisely removed from a solid block using computer-controlled tools, offering high accuracy and excellent surface finish for complex geometries. 3D printing, or additive manufacturing, builds plastic parts layer-by-layer from digital models, enabling rapid prototyping and customization with minimal material waste. Both methods serve different production needs in plastics fabrication, with CNC machining suited for durable, high-tolerance components and 3D printing excelling in flexible, intricate designs.

Material Compatibility: Plastics in CNC vs 3D Printing

CNC machining excels in handling a wide range of plastics including ABS, polycarbonate, acrylic, and nylon with high precision and material strength retention. 3D printing supports a diverse array of plastics such as PLA, PETG, TPU, and specialized engineering-grade materials but may exhibit limitations in durability and surface finish compared to CNC. The choice depends on the required mechanical properties, complexity, and post-processing needs of the plastic component.

Precision and Tolerances in Plastic Parts

CNC machining offers superior precision and tighter tolerances in plastic parts, typically achieving tolerances as fine as +-0.005 mm, making it ideal for applications demanding high accuracy and repeatability. 3D printing generally provides broader tolerances around +-0.1 mm, which is suitable for prototype development and complex geometries but may lack the fine detail required for functional plastic components. The choice between CNC machining and 3D printing depends on the criticality of precision and the dimensional consistency of the plastic parts in industrial or production environments.

Speed and Production Time: Which Is Faster?

CNC machining offers faster production times for large-scale plastic parts due to its high precision and automated processes, especially in batch runs exceeding dozens of units. 3D printing excels in rapid prototyping and small production runs by eliminating tooling setup, enabling quicker turnaround for complex plastic geometries. Choosing between CNC machining and 3D printing depends on the required production volume and part complexity, with CNC favored for speed in mass production and 3D printing optimal for fast, custom iterations.

Cost Comparison: CNC Machining vs 3D Printing Plastics

CNC machining of plastics typically incurs higher initial setup costs due to tooling and programming but offers lower per-unit costs for large production runs, making it cost-effective for high volumes. In contrast, 3D printing plastics, especially with technologies like SLA or FDM, minimizes upfront expenses and excels in prototyping or low-volume manufacturing but often results in higher per-part costs and slower production times. Material costs for 3D printed plastics vary widely based on filament or resin type, whereas CNC machining relies on bulk plastic stock, impacting overall cost efficiency depending on project scale.

Surface Finish and Aesthetics of Plastic Components

CNC machining produces plastic components with superior surface finish due to its precise cutting tools and controlled machining processes, resulting in smooth, high-quality surfaces ideal for functional and aesthetic applications. 3D printing often leaves visible layer lines and surface roughness, requiring post-processing for improved aesthetics, which can increase production time and cost. For parts demanding fine detail and polished aesthetics, CNC machining is preferred, while 3D printing suits rapid prototyping where surface finish is less critical.

Design Flexibility and Complexity

CNC machining offers high precision and smooth surface finishes ideal for simple to moderately complex plastic parts but is limited by tool access and subtractive manufacturing constraints. 3D printing excels in producing highly intricate and complex geometries with internal structures and undercuts impossible for CNC, enabling unparalleled design flexibility in plastic prototyping and production. The choice depends on balancing cost, material properties, and required detail complexity for optimized plastic component manufacturing.

Sustainability and Waste Management in Plastic Fabrication

CNC machining in plastic fabrication generates significant waste as it involves subtractive processes that remove excess material, whereas 3D printing produces minimal waste by building parts layer-by-layer, optimizing material usage. The energy consumption of 3D printing varies depending on the technology but often proves more sustainable due to reduced material scrap and opportunities for recycling feedstock. Advanced 3D printing techniques also enable the use of bio-based and recycled plastics, enhancing sustainability compared to traditional CNC machining methods reliant on virgin plastic sheets.

Choosing the Right Method for Your Plastic Product

CNC machining offers high precision and excellent surface finish for plastic products requiring tight tolerances and complex geometries, making it ideal for functional prototypes and end-use parts. 3D printing excels in rapid prototyping with complex, customized designs and lower upfront costs, suitable for iterative development and low-volume production. Selecting the right method depends on factors like production volume, design complexity, material properties, and budget constraints.

CNC Machining vs 3D Printing Infographic

materialdif.com

materialdif.com