Food-grade plastic is specifically designed to be safe for storing and packaging food, meeting strict regulatory standards to prevent harmful chemicals from leaching into consumables. Non-food-grade plastic lacks these safety certifications and may contain toxic additives that pose health risks when in contact with food. Choosing food-grade plastic ensures product safety, maintains food quality, and protects consumers from potential contamination.

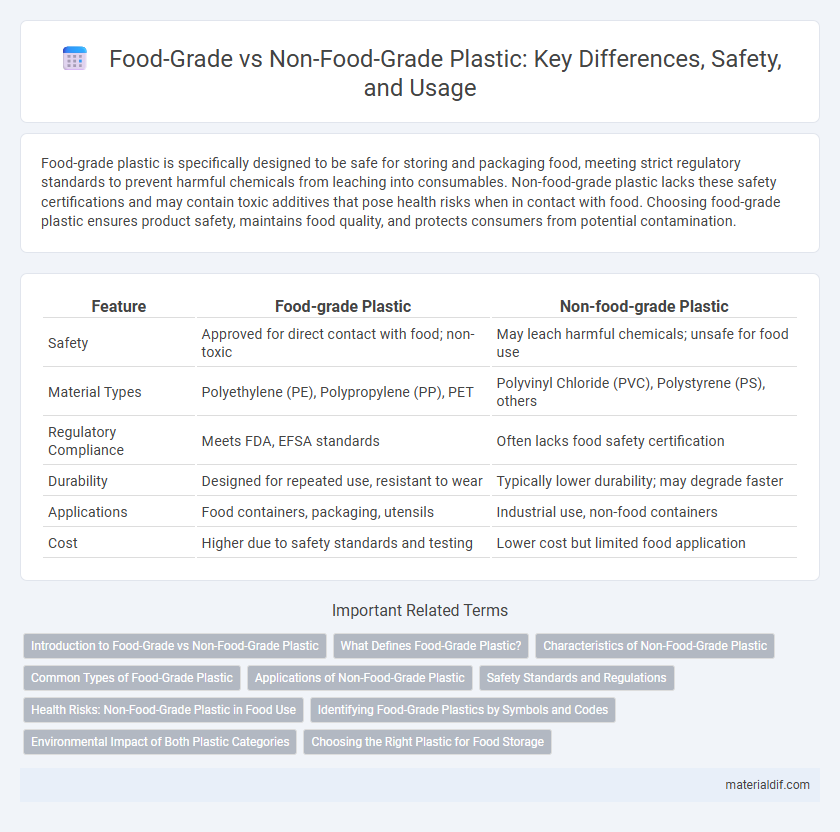

Table of Comparison

| Feature | Food-grade Plastic | Non-food-grade Plastic |

|---|---|---|

| Safety | Approved for direct contact with food; non-toxic | May leach harmful chemicals; unsafe for food use |

| Material Types | Polyethylene (PE), Polypropylene (PP), PET | Polyvinyl Chloride (PVC), Polystyrene (PS), others |

| Regulatory Compliance | Meets FDA, EFSA standards | Often lacks food safety certification |

| Durability | Designed for repeated use, resistant to wear | Typically lower durability; may degrade faster |

| Applications | Food containers, packaging, utensils | Industrial use, non-food containers |

| Cost | Higher due to safety standards and testing | Lower cost but limited food application |

Introduction to Food-Grade vs Non-Food-Grade Plastic

Food-grade plastic is specifically designed to meet safety standards for contact with consumables, ensuring it is free from harmful chemicals that could leach into food or beverages. Non-food-grade plastic may contain additives and contaminants unsuitable for ingestion, often used in industrial applications or non-edible product packaging. Understanding the distinction between these plastics is critical for health safety, regulatory compliance, and preventing chemical contamination in food storage and packaging.

What Defines Food-Grade Plastic?

Food-grade plastic is defined by its compliance with strict safety standards set by regulatory agencies such as the FDA, ensuring it does not leach harmful chemicals into food or beverages. These plastics are made from materials like high-density polyethylene (HDPE) or polypropylene (PP), which resist contamination and maintain purity during storage and handling. Non-food-grade plastics lack this certification, often containing additives or impurities that pose health risks when in contact with consumables.

Characteristics of Non-Food-Grade Plastic

Non-food-grade plastics often contain additives, plasticizers, and stabilizers that can leach harmful chemicals when exposed to heat or acidic foods, posing health risks. These plastics typically lack the certifications and rigorous testing required for food safety, resulting in potential contamination and degradation over time. Their porous structure and susceptibility to cracking also make them unsuitable for repeated food contact or sterilization processes.

Common Types of Food-Grade Plastic

Polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP) are common types of food-grade plastics due to their chemical resistance and safety for food contact. These plastics meet stringent FDA regulations and do not leach harmful substances into food, ensuring consumer health. In contrast, non-food-grade plastics like polyvinyl chloride (PVC) and polystyrene may release toxins and are unsuitable for direct food storage or packaging.

Applications of Non-Food-Grade Plastic

Non-food-grade plastics are widely used in industrial applications such as packaging for detergents, automotive parts, and construction materials due to their durability and cost-effectiveness. These plastics often contain additives or contaminants that make them unsuitable for direct food contact, limiting their use in consumer goods involving ingestion. Common types of non-food-grade plastics include polyvinyl chloride (PVC) and acrylonitrile butadiene styrene (ABS), which offer specific physical properties tailored for mechanical and chemical resistance in harsh environments.

Safety Standards and Regulations

Food-grade plastic complies with strict safety standards set by regulatory agencies such as the FDA and EFSA, ensuring materials are free from harmful chemicals and safe for direct contact with food. Non-food-grade plastics often lack certification for food safety, potentially leaching toxic substances like BPA or phthalates into food products. Compliance with migration limits and rigorous testing protocols distinguishes food-grade plastics in maintaining consumer health and regulatory adherence.

Health Risks: Non-Food-Grade Plastic in Food Use

Non-food-grade plastic contains harmful chemicals such as BPA, phthalates, and heavy metals that can leach into food and cause endocrine disruption, hormonal imbalances, and increased cancer risk. Consuming food stored or packaged in non-food-grade plastic increases the likelihood of gastrointestinal issues, allergic reactions, and long-term toxicity. Regulatory agencies strictly recommend using only food-grade plastics certified for safety to minimize exposure to these health hazards.

Identifying Food-Grade Plastics by Symbols and Codes

Food-grade plastics are identified by specific recycling codes such as #1 (PET), #2 (HDPE), #4 (LDPE), and #5 (PP), which indicate materials safe for food contact due to their chemical properties and manufacturing standards. Non-food-grade plastics often contain additives or contaminants that can leach harmful substances into food, and these are usually marked with codes like #3 (PVC), #6 (PS), or #7 (Other). Recognizing these symbols on packaging ensures safe food storage and reduces the risk of toxic exposure.

Environmental Impact of Both Plastic Categories

Food-grade plastic is designed to be chemically stable and safer for packaging consumables, minimizing the risk of harmful substances leaching into food but still contributes to environmental pollution if not recycled properly. Non-food-grade plastic often contains additives and chemicals that can leach toxins into the environment, posing greater risks to soil and water contamination during degradation or incineration. Both categories contribute to plastic waste accumulation, but food-grade plastics tend to have stricter recycling guidelines and regulations aimed at reducing environmental impact.

Choosing the Right Plastic for Food Storage

Food-grade plastic is specifically designed to prevent harmful chemicals from leaching into food, meeting strict FDA regulations for safety and suitability in contact with consumables. Non-food-grade plastic often contains additives or contaminants that can migrate into stored food, posing health risks over prolonged use. Choosing BPA-free, food-grade containers made from polyethylene or polypropylene ensures durability, chemical resistance, and safer preservation of food quality.

Food-grade Plastic vs Non-food-grade Plastic Infographic

materialdif.com

materialdif.com