Engineering plastics offer superior mechanical properties, thermal stability, and chemical resistance compared to commodity plastics, making them ideal for high-performance applications in automotive, electronics, and industrial components. Commodity plastics are typically more cost-effective and easier to process, used widely in packaging, household goods, and disposable items where performance demands are lower. Selecting between engineering and commodity plastics depends on the balance of cost efficiency and material performance required for the intended application.

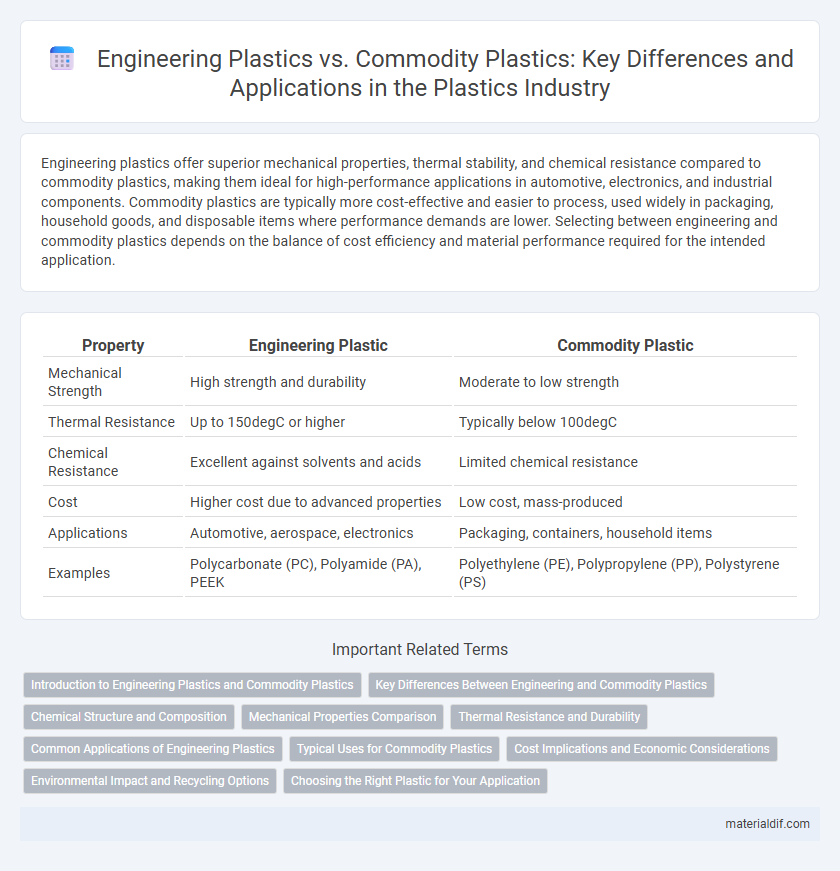

Table of Comparison

| Property | Engineering Plastic | Commodity Plastic |

|---|---|---|

| Mechanical Strength | High strength and durability | Moderate to low strength |

| Thermal Resistance | Up to 150degC or higher | Typically below 100degC |

| Chemical Resistance | Excellent against solvents and acids | Limited chemical resistance |

| Cost | Higher cost due to advanced properties | Low cost, mass-produced |

| Applications | Automotive, aerospace, electronics | Packaging, containers, household items |

| Examples | Polycarbonate (PC), Polyamide (PA), PEEK | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) |

Introduction to Engineering Plastics and Commodity Plastics

Engineering plastics are high-performance materials characterized by superior mechanical strength, thermal stability, and resistance to wear and chemicals, making them ideal for demanding applications in automotive, aerospace, and electronics industries. Commodity plastics, such as polyethylene, polypropylene, and polystyrene, are produced in large volumes for everyday use due to their cost-effectiveness and ease of processing, suitable for packaging, containers, and household products. The distinction lies in engineering plastics' enhanced durability and functionality compared to the more basic, economically driven applications of commodity plastics.

Key Differences Between Engineering and Commodity Plastics

Engineering plastics, such as polycarbonate and nylon, offer superior mechanical strength, thermal resistance, and durability compared to commodity plastics like polyethylene and polypropylene, which are primarily used for low-cost, high-volume applications. Engineering plastics are designed for performance in demanding environments with higher impact resistance and dimensional stability, while commodity plastics excel in cost-effectiveness and ease of processing for everyday products. The key differences lie in their molecular structure, thermal properties, and application scope, making engineering plastics ideal for automotive parts and electronics, whereas commodity plastics dominate packaging and disposable items.

Chemical Structure and Composition

Engineering plastics possess complex, high-performance chemical structures characterized by aromatic rings or polar groups, granting superior thermal resistance and mechanical strength. Commodity plastics are composed of simpler, linear or branched polymers like polyethylene or polypropylene with non-polar hydrocarbon chains, resulting in lower cost but reduced durability. Differences in molecular weight, crystallinity, and additives significantly impact their physical properties and application suitability.

Mechanical Properties Comparison

Engineering plastics such as polycarbonate, nylon, and acetal exhibit superior mechanical properties compared to commodity plastics like polyethylene and polypropylene, including higher tensile strength, better impact resistance, and greater dimensional stability. These enhanced mechanical characteristics enable engineering plastics to perform reliably under demanding conditions, such as high stress, elevated temperatures, and continuous wear. Commodity plastics are preferred for applications where cost efficiency outweighs the need for advanced mechanical performance.

Thermal Resistance and Durability

Engineering plastics, such as polycarbonate and PEEK, exhibit superior thermal resistance withstanding temperatures typically above 150degC, compared to commodity plastics like polyethylene and polypropylene that degrade around 80-100degC. The durability of engineering plastics includes enhanced mechanical strength and resistance to environmental stress cracking, making them ideal for demanding applications. Commodity plastics offer cost-effective solutions for less demanding uses but lack the thermal stability and longevity of engineering-grade materials.

Common Applications of Engineering Plastics

Engineering plastics are widely used in automotive components, electrical connectors, and industrial machinery due to their superior mechanical strength, thermal stability, and chemical resistance. Common materials such as polycarbonate, polyamide (nylon), and polyoxymethylene (POM) enhance durability and performance in demanding environments. These plastics enable precision parts, gears, and structural applications where commodity plastics like polyethylene or polypropylene would fail.

Typical Uses for Commodity Plastics

Commodity plastics, such as polyethylene, polypropylene, polystyrene, and polyvinyl chloride (PVC), are widely used in packaging, containers, and household products due to their affordability and ease of processing. These plastics offer moderate mechanical properties suitable for applications like plastic bags, bottles, and disposable cutlery. Their versatility and cost-effectiveness make them ideal for mass-produced consumer goods and everyday items.

Cost Implications and Economic Considerations

Engineering plastics, including polycarbonate and nylon, exhibit higher material costs but offer superior mechanical properties and durability, leading to longer product lifespans and lower maintenance expenses. Commodity plastics such as polyethylene and polypropylene provide cost-effective solutions for high-volume, low-complexity applications but may incur increased replacement and failure costs due to inferior performance. Economic considerations must balance upfront material expenses with lifecycle costs, factoring in application requirements, production scale, and product longevity to optimize overall expenditure.

Environmental Impact and Recycling Options

Engineering plastics, such as polycarbonate and nylon, offer superior durability and heat resistance but pose greater environmental challenges due to complex recycling processes and lower biodegradability. Commodity plastics like polyethylene and polypropylene are easier to recycle and have more established recycling streams, though they often lack the performance properties needed for demanding applications. The environmental impact of engineering plastics is amplified by limited recycling infrastructure, leading to increased reliance on energy-intensive disposal methods like incineration or landfill.

Choosing the Right Plastic for Your Application

Engineering plastics, such as polycarbonate, nylon, and acetal, offer superior mechanical strength, thermal resistance, and dimensional stability compared to commodity plastics like polyethylene and polypropylene. Selecting the right plastic depends on the application's performance requirements, including load-bearing capacity, temperature tolerance, and chemical resistance. Cost-effectiveness and ease of processing are critical factors when balancing the choice between high-performance engineering plastics and more economical commodity plastics.

Engineering Plastic vs Commodity Plastic Infographic

materialdif.com

materialdif.com