Co-polymers consist of two or more different monomers combined to enhance material properties like flexibility, toughness, and chemical resistance, making them suitable for diverse applications. Homo-polymers are made from a single type of monomer, resulting in consistent molecular structure and predictable physical characteristics helpful in standard manufacturing processes. The choice between co-polymer and homo-polymer depends on the desired performance attributes and processing requirements in plastic production.

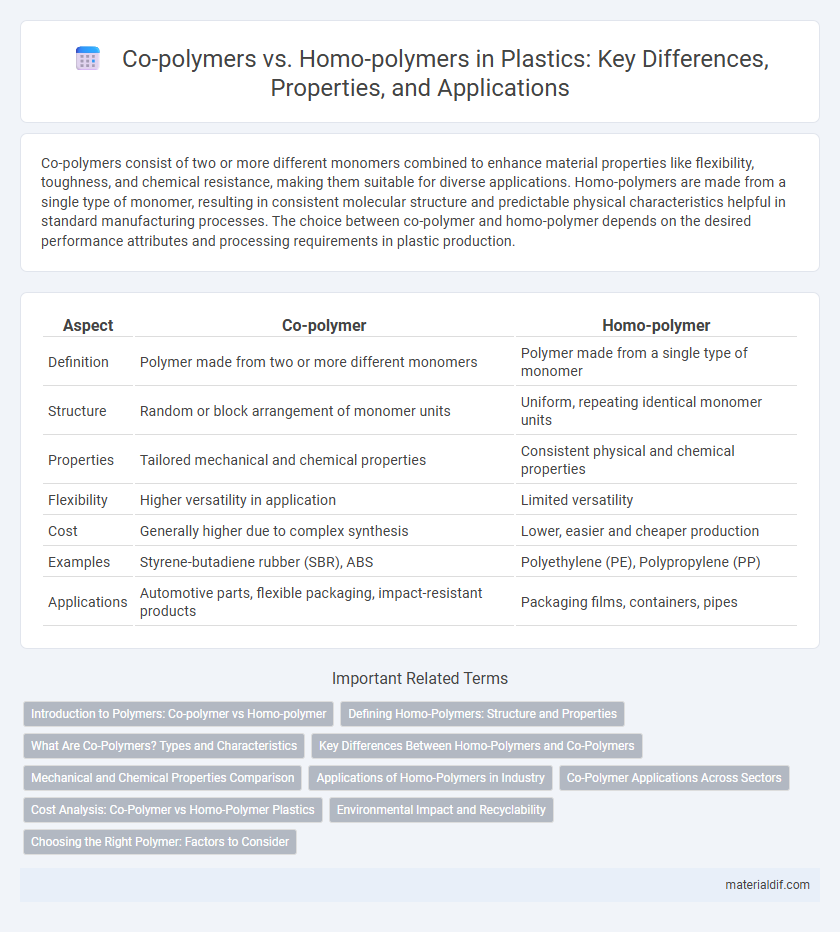

Table of Comparison

| Aspect | Co-polymer | Homo-polymer |

|---|---|---|

| Definition | Polymer made from two or more different monomers | Polymer made from a single type of monomer |

| Structure | Random or block arrangement of monomer units | Uniform, repeating identical monomer units |

| Properties | Tailored mechanical and chemical properties | Consistent physical and chemical properties |

| Flexibility | Higher versatility in application | Limited versatility |

| Cost | Generally higher due to complex synthesis | Lower, easier and cheaper production |

| Examples | Styrene-butadiene rubber (SBR), ABS | Polyethylene (PE), Polypropylene (PP) |

| Applications | Automotive parts, flexible packaging, impact-resistant products | Packaging films, containers, pipes |

Introduction to Polymers: Co-polymer vs Homo-polymer

Co-polymers consist of two or more different monomer units chemically bonded in the polymer chain, offering tailored material properties such as enhanced flexibility, strength, or chemical resistance compared to homo-polymers, which are made from a single type of monomer. The molecular structure of homo-polymers results in uniform properties, often used in applications requiring consistent performance, while co-polymers enable customizable functionalities suited for specialized industrial uses. Key types of co-polymers include random, block, and graft co-polymers, each influencing the physical and mechanical characteristics of the resulting plastic.

Defining Homo-Polymers: Structure and Properties

Homo-polymers consist of identical repeating monomer units, resulting in a uniform molecular structure that offers consistent physical and chemical properties. Their straightforward composition typically yields higher crystallinity, enhancing strength, rigidity, and thermal stability compared to co-polymers. Common examples include polyethylene and polystyrene, widely used in packaging and consumer goods due to their predictable behavior and durability.

What Are Co-Polymers? Types and Characteristics

Co-polymers are polymers formed by polymerizing two or more different monomers, offering tailored properties unattainable by homo-polymers, which consist of a single monomer type. Common types of co-polymers include random, block, alternating, and graft co-polymers, each exhibiting distinct molecular arrangements that influence mechanical strength, thermal stability, and chemical resistance. This versatility allows co-polymers to be used in diverse applications such as automotive parts, packaging materials, and biomedical devices, where specific performance characteristics are critical.

Key Differences Between Homo-Polymers and Co-Polymers

Homo-polymers consist of identical monomer units linked in a single chain, resulting in consistent physical properties and simple molecular structure. Co-polymers are composed of two or more different monomer types, allowing for tailored properties such as improved toughness, flexibility, or chemical resistance through varying monomer ratios and arrangements. The key differences lie in their chemical composition, performance characteristics, and potential applications, with co-polymers offering enhanced versatility compared to homo-polymers.

Mechanical and Chemical Properties Comparison

Co-polymers exhibit enhanced mechanical properties such as improved toughness, flexibility, and impact resistance compared to homo-polymers due to the incorporation of different monomer units that create more complex polymer structures. Chemically, co-polymers offer greater resistance to solvents, UV radiation, and thermal degradation, as variations in monomer composition lead to tailored chemical stability and durability. Homo-polymers, composed of identical monomers, generally provide higher crystallinity and tensile strength but lack the versatility in mechanical adaptability and chemical resistance found in co-polymers.

Applications of Homo-Polymers in Industry

Homo-polymers, such as polyethylene and polypropylene, are extensively used in packaging, automotive parts, and consumer goods due to their uniform molecular structure and consistent physical properties. Their high crystallinity enhances mechanical strength and chemical resistance, making them ideal for container manufacturing, piping, and textile fibers. Industries favor homo-polymers for applications requiring durability, ease of processing, and cost-effectiveness.

Co-Polymer Applications Across Sectors

Co-polymers exhibit enhanced versatility in sectors such as automotive, packaging, and textiles due to their tailored properties like improved impact resistance and flexibility. Their ability to combine diverse monomers enables customization for specific applications, including medical devices and electronics, where performance and durability are critical. Industries increasingly rely on co-polymers for lightweight, high-strength materials that optimize product efficiency and lifespan.

Cost Analysis: Co-Polymer vs Homo-Polymer Plastics

Co-polymers typically incur higher production costs compared to homo-polymers due to the complexity of polymerization processes and the use of multiple monomers, impacting overall pricing in plastic manufacturing. Homo-polymers benefit from streamlined synthesis and abundant raw materials, resulting in lower material and processing expenses. Cost analysis for applications must weigh the performance advantages of co-polymers against the economic efficiency of homo-polymers to optimize budget and product requirements.

Environmental Impact and Recyclability

Co-polymers typically exhibit enhanced recyclability compared to homo-polymers due to their tailored molecular structures, which facilitate breakdown and reuse, reducing environmental pollution. Homo-polymers, composed of a single type of monomer, often present simpler recycling processes but may generate greater environmental impact due to less versatility in degradation. The environmental footprint of co-polymers can be lower when designed for specific applications, promoting sustainability through improved lifecycle management and waste reduction.

Choosing the Right Polymer: Factors to Consider

Choosing the right polymer between co-polymer and homo-polymer depends on factors such as mechanical properties, chemical resistance, and processing requirements. Co-polymers offer enhanced flexibility and impact resistance due to the combination of different monomers, while homo-polymers typically provide higher crystallinity and strength from uniform repeating units. Evaluating application-specific demands like temperature tolerance, cost efficiency, and durability ensures optimal polymer selection for manufacturing and performance goals.

Co-polymer vs Homo-polymer Infographic

materialdif.com

materialdif.com