Nylon 6 and Nylon 66 are both widely used polyamides known for their strength, durability, and resistance to abrasion. Nylon 6 is produced from a single type of monomer, caprolactam, offering better impact resistance and flexibility, while Nylon 66, made from hexamethylene diamine and adipic acid, typically provides higher melting points and superior tensile strength. The choice between Nylon 6 and Nylon 66 depends on specific application requirements such as thermal stability, moisture absorption, and mechanical performance.

Table of Comparison

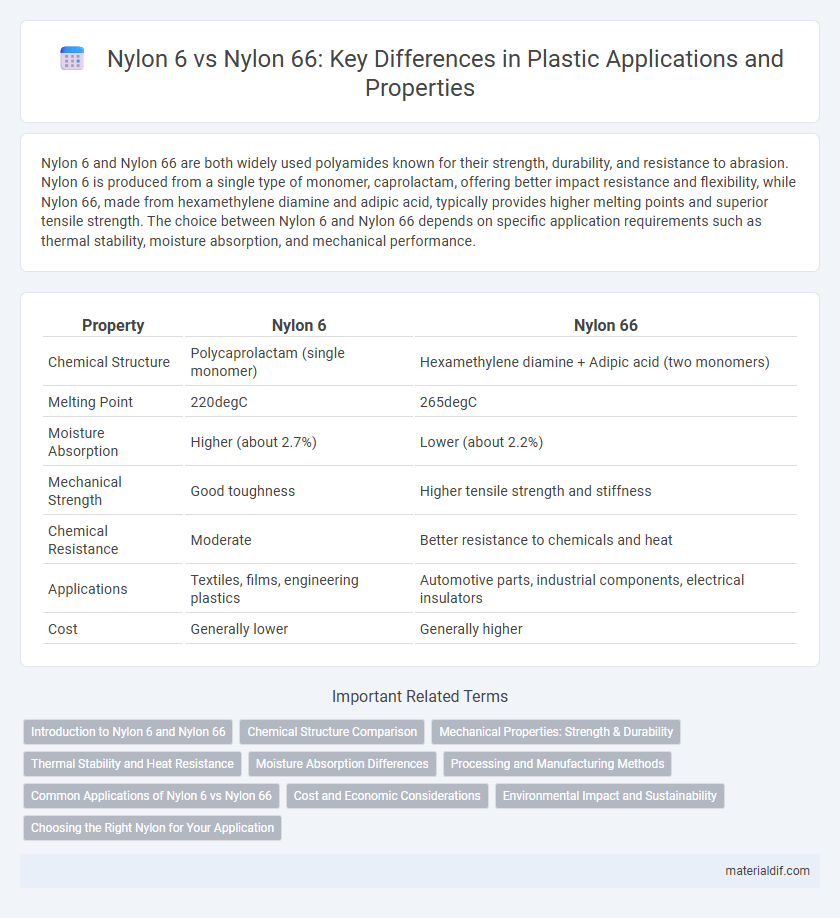

| Property | Nylon 6 | Nylon 66 |

|---|---|---|

| Chemical Structure | Polycaprolactam (single monomer) | Hexamethylene diamine + Adipic acid (two monomers) |

| Melting Point | 220degC | 265degC |

| Moisture Absorption | Higher (about 2.7%) | Lower (about 2.2%) |

| Mechanical Strength | Good toughness | Higher tensile strength and stiffness |

| Chemical Resistance | Moderate | Better resistance to chemicals and heat |

| Applications | Textiles, films, engineering plastics | Automotive parts, industrial components, electrical insulators |

| Cost | Generally lower | Generally higher |

Introduction to Nylon 6 and Nylon 66

Nylon 6 and Nylon 66 are two prominent types of synthetic polyamides widely used in the plastics industry for their strength and versatility. Nylon 6 is produced through the ring-opening polymerization of caprolactam, resulting in a polymer with good elasticity and impact resistance. Nylon 66 is synthesized by polycondensation of hexamethylenediamine and adipic acid, offering higher melting points and superior abrasion resistance compared to Nylon 6.

Chemical Structure Comparison

Nylon 6 is a polyamide derived from caprolactam, featuring a single type of amide group with repeating units of (C6H11NO), whereas Nylon 66 consists of hexamethylene diamine and adipic acid, resulting in repeating units of (C12H22N2O2) with two amide linkages per repeating unit. The chemical structure of Nylon 6 gives it a more uniform molecular chain, contributing to its higher elasticity and better dye absorption. Nylon 66's alternating hexamethylene and adipic acid units create stronger intermolecular hydrogen bonding, enhancing its tensile strength and thermal resistance compared to Nylon 6.

Mechanical Properties: Strength & Durability

Nylon 6 offers high tensile strength and excellent impact resistance, making it suitable for a variety of mechanical applications. Nylon 66 exhibits superior durability and thermal stability due to its higher melting point and crystallinity, which enhances wear resistance in demanding environments. Both materials provide strong mechanical properties, but Nylon 66 typically outperforms Nylon 6 in long-term strength retention and toughness under high-stress conditions.

Thermal Stability and Heat Resistance

Nylon 6 and Nylon 66 differ notably in thermal stability and heat resistance, with Nylon 66 exhibiting higher melting points around 265degC compared to Nylon 6's 220degC, making Nylon 66 more suitable for high-temperature applications. The enhanced crystallinity of Nylon 66 contributes to its superior heat resistance and dimensional stability under prolonged thermal exposure. Nylon 6, while less heat resistant, offers better impact strength and flexibility, balancing performance criteria depending on thermal demands.

Moisture Absorption Differences

Nylon 6 absorbs more moisture than Nylon 66 due to its single-chain amide structure, resulting in higher water uptake and increased dimensional changes. Nylon 66's closely packed molecular arrangement and higher crystallinity limit moisture absorption, enhancing its mechanical stability in humid environments. This difference impacts their suitability for applications requiring moisture resistance, with Nylon 66 preferred for high-performance engineering uses.

Processing and Manufacturing Methods

Nylon 6 is typically produced through ring-opening polymerization of caprolactam, allowing seamless extrusion and injection molding with faster cycle times. Nylon 66, synthesized via condensation polymerization of hexamethylene diamine and adipic acid, requires higher processing temperatures and longer drying times to prevent hydrolysis during manufacturing. Both materials exhibit distinct thermal behaviors influencing the selection of processing techniques such as extrusion, injection molding, or fiber spinning in industrial applications.

Common Applications of Nylon 6 vs Nylon 66

Nylon 6 is widely used in textile fibers, industrial yarns, and molded parts due to its excellent elasticity and abrasion resistance. Nylon 66 dominates in automotive components, electrical connectors, and high-performance mechanical parts because of its superior heat resistance and tensile strength. Both materials play crucial roles in producing durable consumer goods, but Nylon 66 is preferred for applications requiring greater thermal stability and mechanical durability.

Cost and Economic Considerations

Nylon 6 generally offers a lower production cost due to its simpler polymerization process compared to Nylon 66, making it more economically viable for high-volume manufacturing. Nylon 66 provides superior mechanical strength and thermal resistance, which can justify its higher price in applications demanding enhanced durability. Cost efficiency often drives the choice of Nylon 6 in consumer products, while Nylon 66 is favored in automotive and industrial sectors where performance outweighs initial material expenses.

Environmental Impact and Sustainability

Nylon 6 and Nylon 66 differ significantly in environmental impact and sustainability due to their production processes. Nylon 6 is synthesized from caprolactam derived from petrochemicals, resulting in lower energy consumption and reduced greenhouse gas emissions compared to Nylon 66, which is produced from hexamethylenediamine and adipic acid, the latter involving nitrous oxide emissions, a potent greenhouse gas. Both materials are recyclable, but Nylon 6's chemical recycling process into caprolactam monomer is more efficient, contributing to enhanced circularity and reduced environmental footprint in textile and engineering applications.

Choosing the Right Nylon for Your Application

Nylon 6 offers superior flexibility and moisture absorption, making it ideal for applications requiring impact resistance and ease of processing, such as textiles and packaging films. Nylon 66 provides higher thermal resistance and tensile strength due to its denser molecular structure, suitable for engineering components exposed to high temperatures and mechanical stress. Selecting between Nylon 6 and Nylon 66 depends on factors like operating environment, mechanical load, and required durability for optimal performance.

Nylon 6 vs Nylon 66 Infographic

materialdif.com

materialdif.com