HDPE (High-Density Polyethylene) features a more rigid structure and higher tensile strength, making it ideal for applications like containers and piping, while LDPE (Low-Density Polyethylene) offers greater flexibility and is commonly used in films and packaging. The density difference impacts their melting points, with HDPE typically having a higher melting point, providing better heat resistance. Chemical resistance in both types is strong, but HDPE tends to withstand harsher environments better than LDPE.

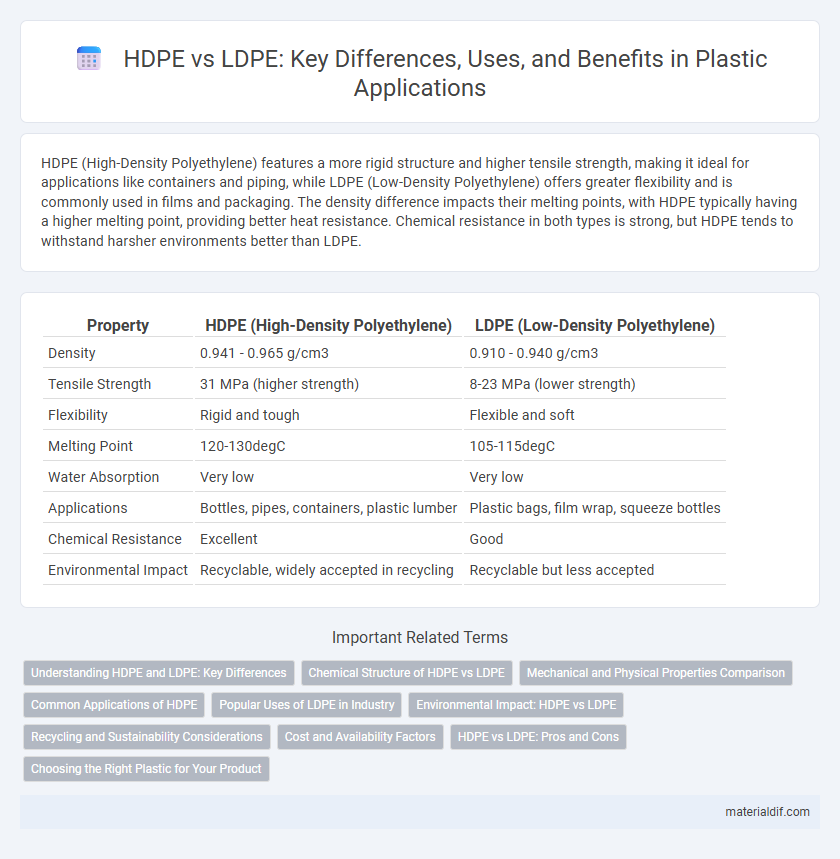

Table of Comparison

| Property | HDPE (High-Density Polyethylene) | LDPE (Low-Density Polyethylene) |

|---|---|---|

| Density | 0.941 - 0.965 g/cm3 | 0.910 - 0.940 g/cm3 |

| Tensile Strength | 31 MPa (higher strength) | 8-23 MPa (lower strength) |

| Flexibility | Rigid and tough | Flexible and soft |

| Melting Point | 120-130degC | 105-115degC |

| Water Absorption | Very low | Very low |

| Applications | Bottles, pipes, containers, plastic lumber | Plastic bags, film wrap, squeeze bottles |

| Chemical Resistance | Excellent | Good |

| Environmental Impact | Recyclable, widely accepted in recycling | Recyclable but less accepted |

Understanding HDPE and LDPE: Key Differences

HDPE (High-Density Polyethylene) exhibits a linear structure with minimal branching, resulting in high tensile strength, rigidity, and resistance to impact, making it suitable for containers, pipes, and geomembranes. LDPE (Low-Density Polyethylene) features extensive branching, creating a more flexible and softer material with lower tensile strength, commonly used in plastic bags, films, and squeezable bottles. The key differences between HDPE and LDPE lie in their density, molecular structure, and mechanical properties, which dictate their distinct applications and durability.

Chemical Structure of HDPE vs LDPE

HDPE (High-Density Polyethylene) features a linear polymer chain with minimal branching, resulting in tightly packed molecules and a higher density compared to LDPE (Low-Density Polyethylene). LDPE contains significant long and short chain branching, which prevents tight packing, leading to lower density and increased flexibility. The differences in chemical structure directly influence their mechanical properties and applications, with HDPE offering greater strength and LDPE providing enhanced pliability.

Mechanical and Physical Properties Comparison

High-Density Polyethylene (HDPE) exhibits superior mechanical strength and higher tensile strength, typically ranging from 20 to 37 MPa, compared to Low-Density Polyethylene's (LDPE) tensile strength of 8 to 23 MPa. HDPE demonstrates greater rigidity and impact resistance due to its linear molecular structure with low branching, while LDPE's branched structure provides enhanced flexibility and elongation at break up to 650%. Physically, HDPE has a higher melting point around 130-137degC, whereas LDPE melts at approximately 105-115degC, influencing their thermal stability and application suitability in packaging and piping industries.

Common Applications of HDPE

HDPE (High-Density Polyethylene) is widely used in applications requiring strong, durable, and chemical-resistant plastic, such as in the manufacturing of milk jugs, detergent bottles, piping, and plastic lumber. Its high tensile strength and resistance to impact make it ideal for containers that must withstand stress without breaking. Common industrial uses include corrosion-resistant piping systems and geomembranes for environmental containment.

Popular Uses of LDPE in Industry

Low-Density Polyethylene (LDPE) is widely used in the packaging industry due to its flexibility, transparency, and moisture resistance. It serves as a primary material for manufacturing plastic bags, containers, and shrink wraps. The chemical industry also utilizes LDPE for corrosion-resistant tubing and seals, benefiting from its low-cost and versatile properties.

Environmental Impact: HDPE vs LDPE

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) differ significantly in environmental impact due to their density and recyclability. HDPE, with its higher density, is more durable and easier to recycle, resulting in a lower overall carbon footprint and less environmental pollution compared to LDPE. LDPE, often used in flexible packaging, tends to degrade more quickly and is less frequently recycled, contributing to higher levels of microplastic pollution and environmental persistence.

Recycling and Sustainability Considerations

HDPE (High-Density Polyethylene) is more widely recycled than LDPE (Low-Density Polyethylene) due to its higher melting point and greater structural integrity, making it suitable for products such as containers and pipes. LDPE, commonly found in plastic bags and film, presents recycling challenges because of its lower density and flexible nature, leading to less efficient processing and fewer recycling facilities accepting it. From a sustainability perspective, HDPE's durability and recyclability contribute to a longer lifecycle and reduced environmental impact, whereas LDPE's limited recyclability often results in higher landfill rates and environmental persistence.

Cost and Availability Factors

HDPE (High-Density Polyethylene) typically has a higher cost than LDPE (Low-Density Polyethylene) due to its greater strength and durability, which supports more demanding applications. LDPE is generally more abundant and widely available, making it a cost-effective choice for packaging and flexible film products. Market availability fluctuates with production capacity and raw material prices, but LDPE often remains more accessible in large volumes.

HDPE vs LDPE: Pros and Cons

HDPE (High-Density Polyethylene) offers superior strength, rigidity, and chemical resistance, making it ideal for heavy-duty containers and piping, while LDPE (Low-Density Polyethylene) provides better flexibility, transparency, and impact resistance, suitable for packaging films and bags. HDPE's higher melting point enhances durability under heat but limits flexibility compared to LDPE's lower melting point, which allows for easier processing and softer textures. Cost efficiency varies, with HDPE being generally more expensive due to its robust properties, whereas LDPE is more economical yet less suitable for structural applications.

Choosing the Right Plastic for Your Product

HDPE (High-Density Polyethylene) offers superior strength and chemical resistance, making it ideal for durable containers, piping, and industrial applications. LDPE (Low-Density Polyethylene) provides greater flexibility and moisture resistance, suitable for packaging films, bags, and squeezable bottles. Selecting between HDPE and LDPE depends on the product's required rigidity, durability, and exposure to environmental factors.

HDPE vs LDPE Infographic

materialdif.com

materialdif.com