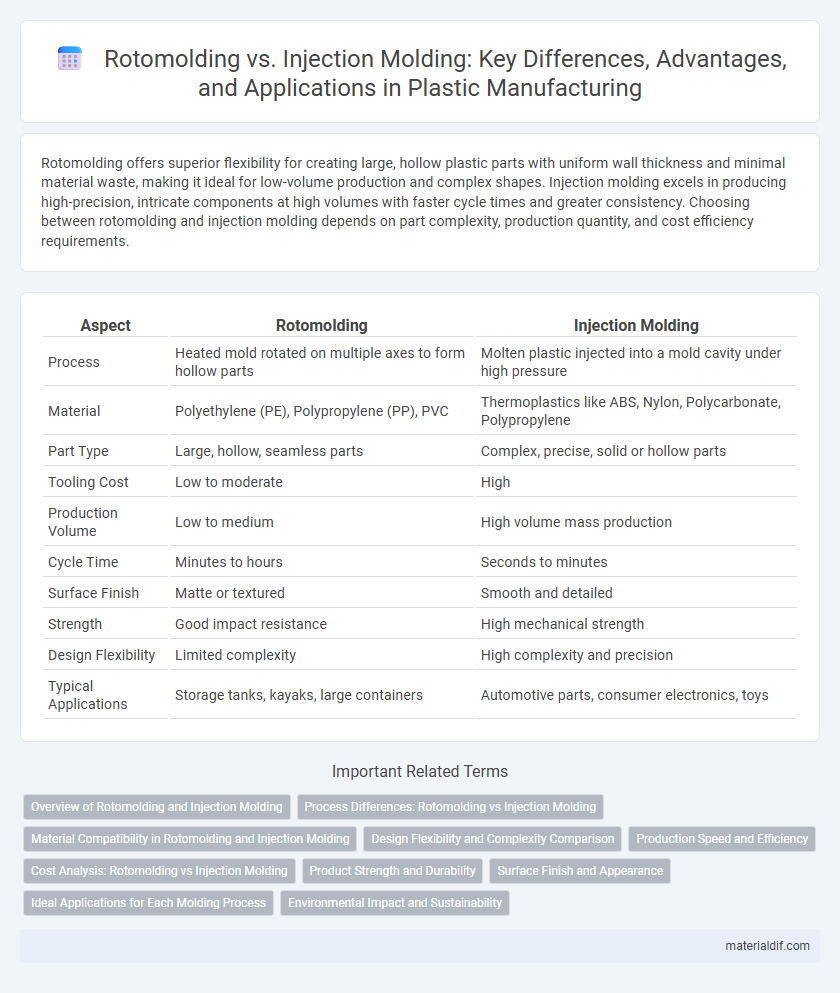

Rotomolding offers superior flexibility for creating large, hollow plastic parts with uniform wall thickness and minimal material waste, making it ideal for low-volume production and complex shapes. Injection molding excels in producing high-precision, intricate components at high volumes with faster cycle times and greater consistency. Choosing between rotomolding and injection molding depends on part complexity, production quantity, and cost efficiency requirements.

Table of Comparison

| Aspect | Rotomolding | Injection Molding |

|---|---|---|

| Process | Heated mold rotated on multiple axes to form hollow parts | Molten plastic injected into a mold cavity under high pressure |

| Material | Polyethylene (PE), Polypropylene (PP), PVC | Thermoplastics like ABS, Nylon, Polycarbonate, Polypropylene |

| Part Type | Large, hollow, seamless parts | Complex, precise, solid or hollow parts |

| Tooling Cost | Low to moderate | High |

| Production Volume | Low to medium | High volume mass production |

| Cycle Time | Minutes to hours | Seconds to minutes |

| Surface Finish | Matte or textured | Smooth and detailed |

| Strength | Good impact resistance | High mechanical strength |

| Design Flexibility | Limited complexity | High complexity and precision |

| Typical Applications | Storage tanks, kayaks, large containers | Automotive parts, consumer electronics, toys |

Overview of Rotomolding and Injection Molding

Rotomolding, also known as rotational molding, is a manufacturing process that uses low pressure to heat and rotate a mold, creating hollow plastic parts with uniform wall thickness and minimal material waste. Injection molding involves injecting molten plastic into a high-precision mold cavity under high pressure, allowing for rapid production of complex and detailed components with tight tolerances. Both methods serve diverse industries, with rotomolding favored for large, hollow products, while injection molding excels in mass-producing intricate, small to medium-sized parts.

Process Differences: Rotomolding vs Injection Molding

Rotomolding uses a heated mold that rotates biaxially, allowing plastic powder to evenly coat the interior, creating hollow, seamless parts ideal for large and complex shapes. Injection molding forces molten plastic into a fixed mold under high pressure, producing highly detailed, precise components suitable for high-volume production. The rotomolding process offers lower tooling costs but longer cycle times, whereas injection molding provides faster production rates and tighter tolerances with higher initial mold investment.

Material Compatibility in Rotomolding and Injection Molding

Rotomolding supports a wide range of polyethylene resins, including low and high-density variants, enabling the production of thick-walled, seamless hollow parts with superior impact resistance and flexibility. Injection molding offers compatibility with a broader spectrum of thermoplastics such as ABS, polycarbonate, and nylon, resulting in precise, complex geometries and high-volume production efficiency. Material selection in rotomolding favors durability and flexibility for large, hollow components, while injection molding excels in rigid, detailed parts requiring tight tolerances.

Design Flexibility and Complexity Comparison

Rotomolding offers superior design flexibility by enabling the creation of large, hollow, and complex shapes without the constraints of parting lines or ejector pins typical in injection molding. Injection molding excels in producing highly detailed, intricate components with tight tolerances, but is limited in design complexity for large, hollow parts due to mold construction limitations. The choice between rotomolding and injection molding depends largely on the product's size, wall thickness uniformity, and design intricacy requirements.

Production Speed and Efficiency

Rotomolding offers slower production speed compared to injection molding, making it more suitable for low to medium volume manufacturing. Injection molding delivers high efficiency and rapid cycle times, enabling mass production of intricate plastic parts with consistent quality. The choice between the two depends on the required production volume, complexity, and cost considerations.

Cost Analysis: Rotomolding vs Injection Molding

Rotomolding typically offers lower initial tooling costs compared to injection molding, making it more cost-effective for small to medium production runs or large hollow parts. Injection molding involves higher upfront mold expenses but achieves significantly faster cycle times, reducing per-unit costs in high-volume manufacturing. Evaluating material usage, labor, and production scale is essential for accurately comparing the overall cost-efficiency between rotomolding and injection molding processes.

Product Strength and Durability

Rotomolding produces thicker, more uniform walls, resulting in enhanced product strength and resistance to impact compared to injection molding. Injection molding achieves precise, intricate designs but often yields thinner walls, which may reduce durability under heavy stress. For applications demanding long-lasting, robust plastic parts, rotomolding is frequently the preferred manufacturing method.

Surface Finish and Appearance

Rotomolding produces seamless, uniform surfaces with a matte or slightly textured finish, ideal for larger and hollow parts requiring consistent wall thickness, while injection molding delivers highly detailed, smooth, and glossy surfaces suited for complex, high-precision components. Injection molding excels in achieving sharp details and intricate textures due to its high-pressure injection process, whereas rotomolding's surface finish is influenced by mold quality and rotational speed, often resulting in less intricate aesthetics. Choosing between rotomolding and injection molding for surface finish depends on the desired level of detail, part complexity, and end-use appearance requirements.

Ideal Applications for Each Molding Process

Rotomolding is ideal for manufacturing large, hollow, and complex-shaped plastic products such as tanks, kayaks, and playground equipment due to its ability to produce stress-free, seamless parts with uniform wall thickness. Injection molding excels in producing high-volume, precise, and intricate components like automotive parts, medical devices, and consumer electronics, offering rapid cycle times and tight tolerances. Choosing between rotomolding and injection molding depends on factors such as part size, production volume, design complexity, and cost efficiency.

Environmental Impact and Sustainability

Rotomolding uses less energy and produces less waste compared to injection molding, making it more environmentally friendly. Injection molding typically consumes more electricity and generates higher levels of scrap due to its high-pressure process. Rotomolding's ability to recycle scrap and use biodegradable or UV-resistant plastics enhances sustainability in plastic manufacturing.

Rotomolding vs Injection Molding Infographic

materialdif.com

materialdif.com