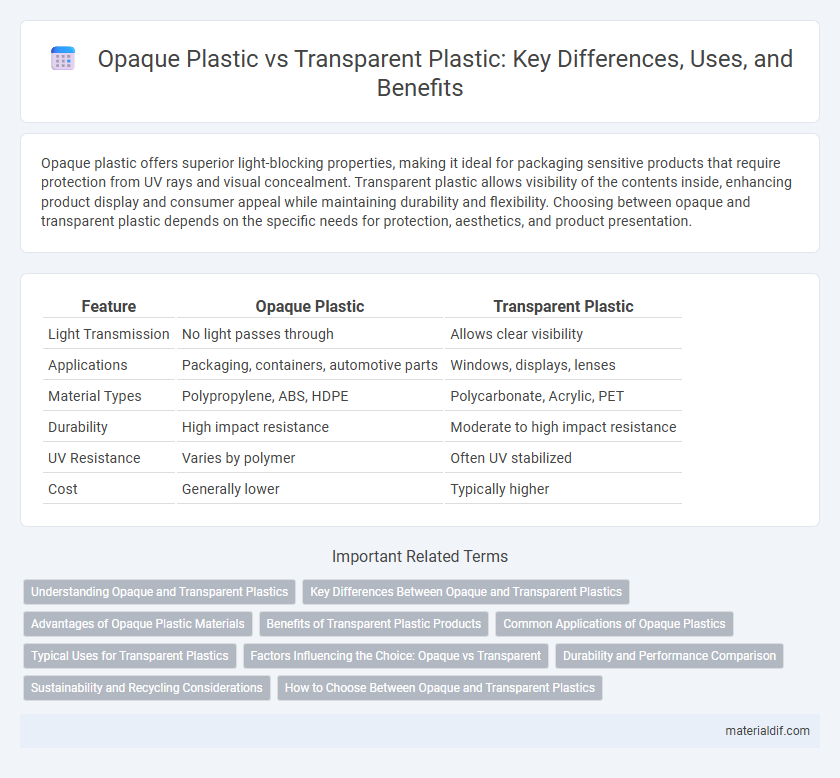

Opaque plastic offers superior light-blocking properties, making it ideal for packaging sensitive products that require protection from UV rays and visual concealment. Transparent plastic allows visibility of the contents inside, enhancing product display and consumer appeal while maintaining durability and flexibility. Choosing between opaque and transparent plastic depends on the specific needs for protection, aesthetics, and product presentation.

Table of Comparison

| Feature | Opaque Plastic | Transparent Plastic |

|---|---|---|

| Light Transmission | No light passes through | Allows clear visibility |

| Applications | Packaging, containers, automotive parts | Windows, displays, lenses |

| Material Types | Polypropylene, ABS, HDPE | Polycarbonate, Acrylic, PET |

| Durability | High impact resistance | Moderate to high impact resistance |

| UV Resistance | Varies by polymer | Often UV stabilized |

| Cost | Generally lower | Typically higher |

Understanding Opaque and Transparent Plastics

Opaque plastics do not allow light to pass through, providing full coverage and privacy, commonly used in packaging, containers, and automotive parts. Transparent plastics, such as polycarbonate and acrylic, offer clear visibility and are widely utilized in optical lenses, windows, and display cases. Understanding the differences in light transmission, durability, and application requirements is essential for selecting the appropriate plastic type in manufacturing and design.

Key Differences Between Opaque and Transparent Plastics

Opaque plastics block light transmission, providing privacy and protection from UV rays, making them ideal for applications like packaging, automotive parts, and household items. Transparent plastics allow light to pass through, enabling clear visibility, which suits uses in lenses, windows, and display cases. The key differences lie in their light permeability, material composition, and application suitability based on visibility and protection needs.

Advantages of Opaque Plastic Materials

Opaque plastic materials provide superior UV resistance, preventing degradation and extending product lifespan in outdoor applications. Their ability to completely block light enhances privacy and protects sensitive contents from photodegradation. Opaque plastics also offer better surface durability and color stability, making them ideal for packaging and automotive components.

Benefits of Transparent Plastic Products

Transparent plastic products offer exceptional clarity and visibility, making them ideal for packaging that showcases contents while protecting them from contaminants. Their lightweight and shatter-resistant properties enhance safety and reduce shipping costs compared to glass. Additionally, transparent plastics like acrylic and polycarbonate provide UV resistance and durability, extending product lifespan in various environmental conditions.

Common Applications of Opaque Plastics

Opaque plastics are widely used in packaging, especially for products sensitive to light, such as pharmaceuticals and food items, where light protection is crucial for preserving quality. They are also common in household goods like containers, furniture, and automotive parts that require durability and aesthetic versatility without transparency. These plastics often serve in electrical enclosures and appliances, providing insulation and shielding internal components from visual exposure and environmental factors.

Typical Uses for Transparent Plastics

Transparent plastics like acrylic and polycarbonate are commonly used in applications requiring clear visibility and light transmission, such as windows, eyewear lenses, and display cases. Their optical clarity makes them ideal for protective shields, signage, and medical device components where transparency is critical. These materials also find extensive use in automotive headlamps and electronic screens, benefiting from their durability and scratch resistance.

Factors Influencing the Choice: Opaque vs Transparent

The choice between opaque and transparent plastic depends primarily on factors such as light transmission, product visibility, and application requirements. Opaque plastics provide UV protection and concealment, making them ideal for packaging sensitive products or ensuring privacy, while transparent plastics offer clarity and aesthetic appeal for display or inspection purposes. Material durability, cost-effectiveness, and environmental resistance also influence the decision, with applications like food packaging, medical devices, and consumer goods dictating specific visibility and protection needs.

Durability and Performance Comparison

Opaque plastic materials generally offer greater durability and resistance to UV light and chemical exposure compared to transparent plastics, making them ideal for outdoor and industrial applications. Transparent plastics like polycarbonate and acrylic provide excellent impact resistance and clarity but may degrade faster under prolonged sunlight or harsh chemical conditions. Performance varies with specific use cases, where opaque plastics excel in protective functions and transparent plastics deliver superior visibility without compromising moderate durability.

Sustainability and Recycling Considerations

Opaque plastic often contains additives and pigments that can complicate recycling processes, reducing its overall sustainability compared to transparent plastic. Transparent plastic is generally easier to sort and recycle, allowing for higher-quality recycled materials and supporting circular economy initiatives. Choosing transparent plastic can therefore enhance material recovery rates and lower environmental impact throughout the product lifecycle.

How to Choose Between Opaque and Transparent Plastics

Choosing between opaque and transparent plastics depends on the application's need for visibility and light transmission. Opaque plastics such as polyethylene and polypropylene offer superior UV resistance and concealment, making them ideal for packaging sensitive products or creating privacy barriers. Transparent plastics like polycarbonate and acrylic enable clear visibility and light passage, which are essential for display cases, lenses, and protective shields.

Opaque Plastic vs Transparent Plastic Infographic

materialdif.com

materialdif.com