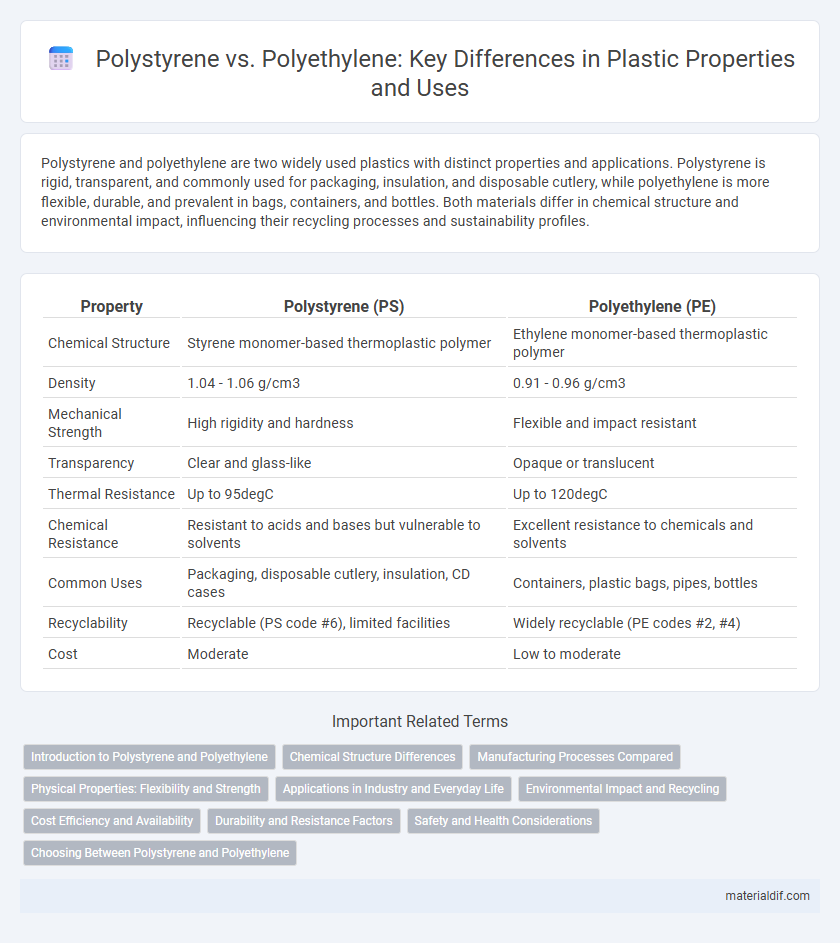

Polystyrene and polyethylene are two widely used plastics with distinct properties and applications. Polystyrene is rigid, transparent, and commonly used for packaging, insulation, and disposable cutlery, while polyethylene is more flexible, durable, and prevalent in bags, containers, and bottles. Both materials differ in chemical structure and environmental impact, influencing their recycling processes and sustainability profiles.

Table of Comparison

| Property | Polystyrene (PS) | Polyethylene (PE) |

|---|---|---|

| Chemical Structure | Styrene monomer-based thermoplastic polymer | Ethylene monomer-based thermoplastic polymer |

| Density | 1.04 - 1.06 g/cm3 | 0.91 - 0.96 g/cm3 |

| Mechanical Strength | High rigidity and hardness | Flexible and impact resistant |

| Transparency | Clear and glass-like | Opaque or translucent |

| Thermal Resistance | Up to 95degC | Up to 120degC |

| Chemical Resistance | Resistant to acids and bases but vulnerable to solvents | Excellent resistance to chemicals and solvents |

| Common Uses | Packaging, disposable cutlery, insulation, CD cases | Containers, plastic bags, pipes, bottles |

| Recyclability | Recyclable (PS code #6), limited facilities | Widely recyclable (PE codes #2, #4) |

| Cost | Moderate | Low to moderate |

Introduction to Polystyrene and Polyethylene

Polystyrene is a versatile synthetic aromatic polymer known for its rigidity, transparency, and ease of molding, commonly used in packaging, insulation, and disposable cutlery. Polyethylene is the most widely produced plastic, characterized by its flexibility, chemical resistance, and diverse applications from plastic bags to containers and pipes. Both materials differ significantly in density, melting points, and mechanical properties, influencing their suitability for various industrial and consumer uses.

Chemical Structure Differences

Polystyrene consists of a polymer chain with a phenyl group attached to every other carbon atom, providing rigid and brittle properties due to its aromatic ring. Polyethylene features a simpler structure with a long chain of repeated ethylene units (-CH2-CH2-), resulting in flexibility and high chemical resistance. The presence of the bulky phenyl group in polystyrene's chemical structure causes higher rigidity and lower density compared to the more linear and flexible polyethylene polymer.

Manufacturing Processes Compared

Polystyrene manufacturing involves polymerizing styrene monomers using suspension or bulk polymerization, resulting in rigid, lightweight foam with excellent insulation properties. Polyethylene production primarily utilizes catalytic polymerization methods, such as Ziegler-Natta or metallocene catalysts, to create varying densities like LDPE, HDPE, and LLDPE with diverse flexibility and strength. The difference in polymerization techniques influences the mechanical properties, thermal resistance, and typical applications of these plastics across industries.

Physical Properties: Flexibility and Strength

Polystyrene exhibits rigid and brittle characteristics with low flexibility, making it ideal for applications requiring structural stiffness but prone to cracking under stress. Polyethylene demonstrates high flexibility and toughness, offering excellent impact resistance and durability suitable for products requiring bendability and resilience. The superior tensile strength of polyethylene compared to polystyrene contributes to its widespread use in packaging films and containers that demand both strength and flexibility.

Applications in Industry and Everyday Life

Polystyrene is widely used in packaging, disposable cutlery, and insulation due to its rigidity and clarity, making it ideal for food containers, CD cases, and foam cups. Polyethylene, known for its flexibility and chemical resistance, dominates applications like plastic bags, bottles, and piping systems in both industrial and household environments. Industrial manufacturing benefits from polystyrene's thermal insulation properties, while polyethylene's durability supports diverse uses in agriculture, automotive components, and consumer goods.

Environmental Impact and Recycling

Polystyrene generates significant environmental challenges due to its low biodegradability and tendency to fragment into harmful microplastics, complicating recycling efforts and contributing to pollution. Polyethylene, while also persistent, offers more efficient recycling streams and is widely accepted in curbside programs, reducing landfill waste. Both plastics demand improved waste management strategies, but polyethylene's recyclability presents a more sustainable option in circular economy models.

Cost Efficiency and Availability

Polystyrene offers moderate cost efficiency and is widely available in rigid foam applications, making it suitable for insulation and packaging. Polyethylene costs less per unit and is more abundant globally, benefiting high-volume production of flexible packaging and containers. The choice depends on required material properties, with polyethylene favored for lower cost and greater availability in mass manufacturing.

Durability and Resistance Factors

Polystyrene offers excellent rigidity and resistance to impact, making it ideal for applications requiring firmness and structural integrity. Polyethylene demonstrates superior chemical resistance and flexibility, enhancing its durability in harsh environmental conditions and repeated stress scenarios. Both plastics excel in different durability and resistance factors, with polystyrene better suited for solid, impact-resistant uses, while polyethylene outperforms in flexibility and chemical exposure resilience.

Safety and Health Considerations

Polystyrene and polyethylene differ significantly in safety and health considerations; polystyrene can release styrene, a potential carcinogen, especially when heated or burned, posing risks in food packaging and consumer products. Polyethylene, being chemically inert and non-toxic, is generally safer for food contact and medical applications, with minimal risk of leaching harmful substances under normal conditions. Proper handling and disposal of polystyrene are crucial to minimize environmental and health hazards, whereas polyethylene's low toxicity offers broader safety in various uses.

Choosing Between Polystyrene and Polyethylene

Polystyrene offers rigidity and excellent insulation, making it ideal for disposable cups and packaging materials, while polyethylene excels in flexibility and chemical resistance, commonly used in plastic bags and containers. Selecting between polystyrene and polyethylene depends on the required durability, environmental impact, and application-specific properties such as thermal resistance or flexibility. Considering recycling capabilities, polyethylene is generally more recyclable and environmentally friendly compared to polystyrene, influencing sustainable material choices.

Polystyrene vs Polyethylene Infographic

materialdif.com

materialdif.com