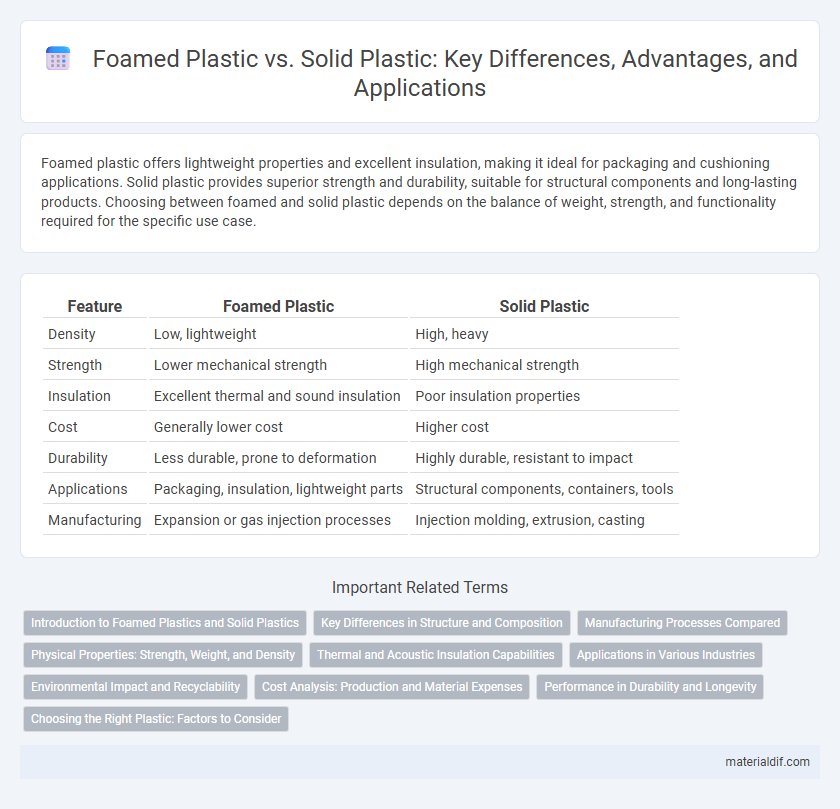

Foamed plastic offers lightweight properties and excellent insulation, making it ideal for packaging and cushioning applications. Solid plastic provides superior strength and durability, suitable for structural components and long-lasting products. Choosing between foamed and solid plastic depends on the balance of weight, strength, and functionality required for the specific use case.

Table of Comparison

| Feature | Foamed Plastic | Solid Plastic |

|---|---|---|

| Density | Low, lightweight | High, heavy |

| Strength | Lower mechanical strength | High mechanical strength |

| Insulation | Excellent thermal and sound insulation | Poor insulation properties |

| Cost | Generally lower cost | Higher cost |

| Durability | Less durable, prone to deformation | Highly durable, resistant to impact |

| Applications | Packaging, insulation, lightweight parts | Structural components, containers, tools |

| Manufacturing | Expansion or gas injection processes | Injection molding, extrusion, casting |

Introduction to Foamed Plastics and Solid Plastics

Foamed plastics are lightweight materials characterized by a cellular structure filled with gas bubbles, providing superior thermal insulation and shock absorption compared to solid plastics. Solid plastics consist of a dense, homogeneous polymer matrix offering higher strength, durability, and resistance to impact and chemicals. Applications of foamed plastics include packaging, insulation, and cushioning, while solid plastics are widely used in automotive parts, construction, and consumer goods.

Key Differences in Structure and Composition

Foamed plastic consists of a polymer matrix filled with gas bubbles, creating a lightweight, porous structure that enhances insulation and cushioning properties. Solid plastic features a dense, homogeneous polymer composition, resulting in higher strength, rigidity, and durability compared to its foamed counterparts. These structural and compositional differences significantly influence the material's applications, thermal performance, and mechanical behavior.

Manufacturing Processes Compared

Foamed plastic manufacturing primarily involves a gas injection or chemical blowing agent process that creates a cellular structure, reducing material density and weight. Solid plastic fabrication typically includes molding techniques like injection molding, extrusion, or compression molding, resulting in dense, non-porous products with higher structural integrity. The foaming process demands precise control over temperature and pressure to ensure uniform cell size, while solid plastic manufacturing emphasizes melt flow and cooling rates for optimal mechanical properties.

Physical Properties: Strength, Weight, and Density

Foamed plastic exhibits lower density and reduced weight compared to solid plastic, making it ideal for lightweight applications requiring moderate strength. Solid plastic offers superior strength and durability due to its dense molecular structure, suitable for high-load and impact-resistant environments. The physical properties balance between foamed and solid plastics determines their optimal use in industries such as packaging, automotive, and construction.

Thermal and Acoustic Insulation Capabilities

Foamed plastic offers superior thermal insulation due to its cellular structure, which traps air and reduces heat transfer, making it ideal for energy-efficient applications. Its porous composition also enhances acoustic insulation by dampening sound waves and minimizing noise transmission compared to solid plastic. In contrast, solid plastic provides higher mechanical strength but lower insulation performance in both thermal and acoustic contexts.

Applications in Various Industries

Foamed plastic, known for its lightweight and cushioning properties, finds extensive applications in packaging, automotive interiors, and insulation in construction, enhancing energy efficiency and impact protection. Solid plastic, characterized by its durability and structural integrity, is widely used in manufacturing durable goods, electronic casings, and medical devices requiring strength and precision. Both materials serve critical roles in industries such as aerospace, consumer goods, and healthcare, where specific performance criteria dictate the choice between foamed and solid plastic solutions.

Environmental Impact and Recyclability

Foamed plastic typically has a lower density, reducing raw material use but often poses greater environmental challenges due to difficulties in recycling and longer degradation times. Solid plastic, while more resource-intensive to produce, is generally more straightforward to recycle, enabling better material recovery and reuse in manufacturing processes. The environmental impact hinges on waste management practices, with solid plastics favoring circular economy goals through established recycling streams.

Cost Analysis: Production and Material Expenses

Foamed plastic typically incurs lower material costs due to its reduced density, which translates to less raw material consumption compared to solid plastic. Production expenses for foamed plastic can be higher because of specialized equipment and processes required to create the cellular structure, but overall manufacturing costs often remain competitive due to savings in weight and material use. Solid plastic production generally involves straightforward molding techniques with consistent material costs, resulting in predictable expenses but higher weight-related shipping and handling costs.

Performance in Durability and Longevity

Foamed plastic offers excellent impact resistance and cushioning properties, making it ideal for applications requiring shock absorption and lightweight durability. Solid plastic exhibits superior structural integrity and higher resistance to wear, chemicals, and environmental factors, ensuring longer lifespan in demanding conditions. Performance in durability and longevity depends on the specific application requirements, with solid plastics favored for strength and foamed plastics for flexibility and energy absorption.

Choosing the Right Plastic: Factors to Consider

Foamed plastic offers superior insulation and cushioning properties compared to solid plastic, making it ideal for packaging and thermal applications. Solid plastic provides greater strength, durability, and structural integrity, suitable for load-bearing and long-term use. Factors to consider when choosing between foamed and solid plastic include weight requirements, thermal insulation needs, mechanical strength, and cost-effectiveness for the intended application.

Foamed Plastic vs Solid Plastic Infographic

materialdif.com

materialdif.com