Plastic PET offers moderate heat resistance, making it suitable for applications involving temperatures up to 80degC without deformation. Its chemical resistance is notable against acids and alcohols but can be compromised by strong bases and solvents. Balancing heat and chemical resistance is essential when selecting PET for packaging or industrial use to ensure durability and safety.

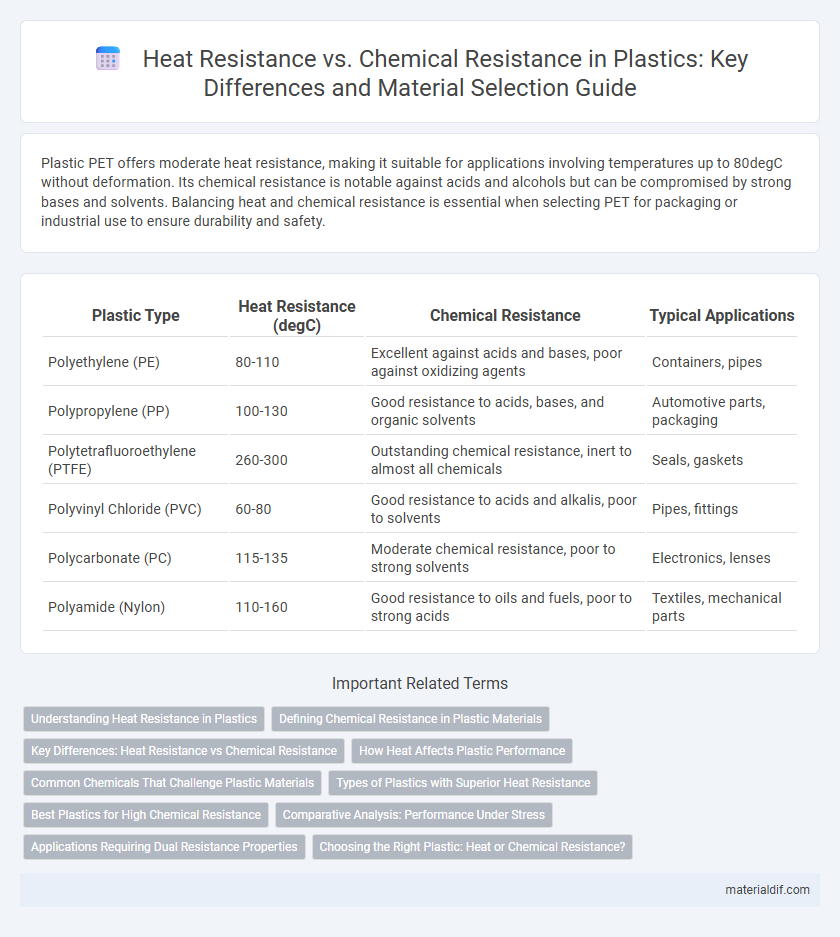

Table of Comparison

| Plastic Type | Heat Resistance (degC) | Chemical Resistance | Typical Applications |

|---|---|---|---|

| Polyethylene (PE) | 80-110 | Excellent against acids and bases, poor against oxidizing agents | Containers, pipes |

| Polypropylene (PP) | 100-130 | Good resistance to acids, bases, and organic solvents | Automotive parts, packaging |

| Polytetrafluoroethylene (PTFE) | 260-300 | Outstanding chemical resistance, inert to almost all chemicals | Seals, gaskets |

| Polyvinyl Chloride (PVC) | 60-80 | Good resistance to acids and alkalis, poor to solvents | Pipes, fittings |

| Polycarbonate (PC) | 115-135 | Moderate chemical resistance, poor to strong solvents | Electronics, lenses |

| Polyamide (Nylon) | 110-160 | Good resistance to oils and fuels, poor to strong acids | Textiles, mechanical parts |

Understanding Heat Resistance in Plastics

Heat resistance in plastics refers to a material's ability to maintain structural integrity and mechanical properties under elevated temperatures. Polymers such as Polyetheretherketone (PEEK) and Polytetrafluoroethylene (PTFE) exhibit exceptional heat resistance, often withstanding continuous exposure to temperatures above 250degC. Understanding thermal stability and glass transition temperature (Tg) is critical for selecting plastics that resist deformation, degradation, or loss of performance in high-heat environments.

Defining Chemical Resistance in Plastic Materials

Chemical resistance in plastic materials refers to the ability of a polymer to withstand degradation or structural changes when exposed to various chemicals such as acids, bases, solvents, or oils. This property is crucial for applications where plastics come into contact with aggressive substances, ensuring durability and maintaining mechanical integrity. Chemical resistance is determined by the polymer's molecular structure, cross-linking density, and the presence of additives or coatings that enhance its stability against chemical attack.

Key Differences: Heat Resistance vs Chemical Resistance

Heat resistance in plastics refers to their ability to maintain structural integrity and mechanical properties at elevated temperatures, typically measured by parameters such as the heat deflection temperature (HDT) or melting point. Chemical resistance, on the other hand, defines a plastic's ability to withstand degradation or reaction when exposed to various chemicals, including acids, bases, and solvents, often evaluated through chemical compatibility charts or immersion tests. Key differences lie in the mechanisms of failure: heat resistance is compromised by thermal deformation or melting, while chemical resistance fails due to molecular breakdown or surface corrosion, making material selection critical based on operating environment.

How Heat Affects Plastic Performance

Heat exposure significantly impacts plastic performance by altering its molecular structure, reducing tensile strength and causing deformation or softening in thermoplastics. High temperatures can accelerate chemical degradation, leading to discoloration, brittleness, and compromised mechanical properties. Heat-resistant plastics like polyphenylene sulfide (PPS) and polyether ether ketone (PEEK) maintain integrity under thermal stress, while chemically resistant plastics may not withstand elevated temperatures without performance loss.

Common Chemicals That Challenge Plastic Materials

Common chemicals that challenge plastic materials include acids such as sulfuric acid and hydrochloric acid, alkaline solutions like sodium hydroxide, and organic solvents including acetone and benzene. Plastics like polyethylene and polypropylene exhibit good resistance to many acids and bases but often degrade when exposed to strong solvents and high temperatures. Heat resistance in plastics like PTFE enhances durability against thermal stress, while chemical resistance depends on the plastic's molecular structure and polymer cross-linking.

Types of Plastics with Superior Heat Resistance

Polyimide, PEEK (polyether ether ketone), and PTFE (polytetrafluoroethylene) exhibit superior heat resistance, maintaining structural integrity at temperatures above 250degC. These high-performance plastics resist thermal degradation, making them ideal for aerospace, electronics, and automotive applications where elevated temperatures are common. Their chemical resistance varies, with PTFE showing exceptional inertness against acids and bases, while polyimide and PEEK balance heat resistance with moderate chemical stability.

Best Plastics for High Chemical Resistance

High chemical resistance in plastics is critical for applications involving aggressive solvents, acids, and bases. Fluoropolymers, such as PTFE and FEP, exhibit exceptional chemical resistance alongside moderate heat resistance, making them ideal for corrosive environments. Polyvinylidene fluoride (PVDF) offers a balance of chemical resistance and higher temperature tolerance, frequently used in chemical processing industries.

Comparative Analysis: Performance Under Stress

Heat resistance in plastics determines their ability to maintain mechanical integrity and dimensional stability at elevated temperatures, with materials like polyether ether ketone (PEEK) excelling above 250degC. Chemical resistance assesses a plastic's durability when exposed to harsh solvents, acids, or bases, where fluoropolymers such as polytetrafluoroethylene (PTFE) demonstrate exceptional inertness. Comparative analysis reveals that while PEEK offers superior thermal endurance critical for high-temperature applications, PTFE provides unparalleled chemical stability but with lower thermal limits, necessitating careful material selection based on specific operational stresses.

Applications Requiring Dual Resistance Properties

Plastics with both heat resistance and chemical resistance are essential in applications such as automotive engine components, chemical processing equipment, and electrical insulation. Polymers like PTFE, PEEK, and PPS maintain structural integrity under high temperatures while resisting corrosive chemicals, ensuring longevity and reliability. Selecting materials with dual resistance properties minimizes maintenance costs and improves safety in demanding industrial environments.

Choosing the Right Plastic: Heat or Chemical Resistance?

Selecting the right plastic depends on the specific demands of heat resistance or chemical resistance required by the application. Polymers like PTFE and PVDF offer exceptional chemical resistance for corrosive environments, while materials such as PEEK and polyimides provide superior heat resistance for high-temperature conditions. Balancing thermal stability with resistance to solvents and acids ensures optimal performance and longevity in industrial and consumer uses.

Heat Resistance vs Chemical Resistance Infographic

materialdif.com

materialdif.com