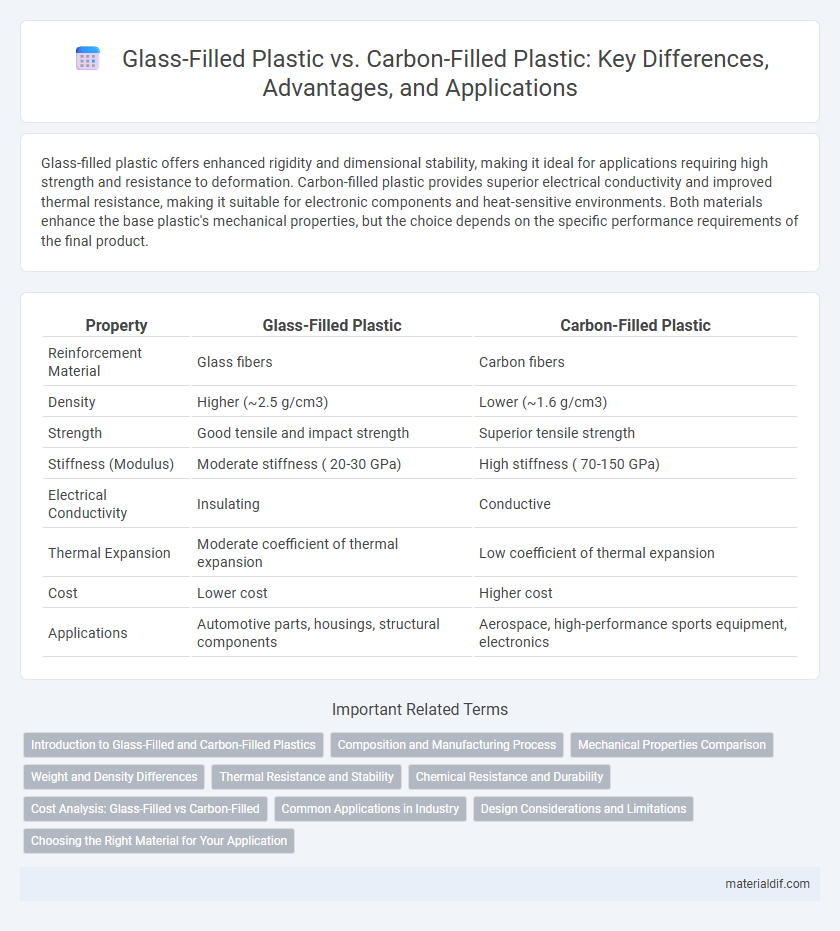

Glass-filled plastic offers enhanced rigidity and dimensional stability, making it ideal for applications requiring high strength and resistance to deformation. Carbon-filled plastic provides superior electrical conductivity and improved thermal resistance, making it suitable for electronic components and heat-sensitive environments. Both materials enhance the base plastic's mechanical properties, but the choice depends on the specific performance requirements of the final product.

Table of Comparison

| Property | Glass-Filled Plastic | Carbon-Filled Plastic |

|---|---|---|

| Reinforcement Material | Glass fibers | Carbon fibers |

| Density | Higher (~2.5 g/cm3) | Lower (~1.6 g/cm3) |

| Strength | Good tensile and impact strength | Superior tensile strength |

| Stiffness (Modulus) | Moderate stiffness ( 20-30 GPa) | High stiffness ( 70-150 GPa) |

| Electrical Conductivity | Insulating | Conductive |

| Thermal Expansion | Moderate coefficient of thermal expansion | Low coefficient of thermal expansion |

| Cost | Lower cost | Higher cost |

| Applications | Automotive parts, housings, structural components | Aerospace, high-performance sports equipment, electronics |

Introduction to Glass-Filled and Carbon-Filled Plastics

Glass-filled plastics consist of a polymer matrix reinforced with glass fibers, providing enhanced strength, stiffness, and thermal stability compared to unfilled plastics. Carbon-filled plastics incorporate carbon fibers or carbon black, offering superior electrical conductivity, increased tensile strength, and improved resistance to fatigue and wear. Both materials are crucial in applications demanding lightweight, durable, and high-performance composite materials for automotive, aerospace, and electronic industries.

Composition and Manufacturing Process

Glass-filled plastic incorporates short glass fibers within a polymer matrix, enhancing strength and dimensional stability through injection molding or extrusion techniques. Carbon-filled plastic uses carbon fibers, which provide superior stiffness and electrical conductivity, typically produced via specialized compounding followed by precision molding. Both materials require controlled processing temperatures and fiber orientation management to optimize mechanical properties and performance.

Mechanical Properties Comparison

Glass-filled plastic offers high tensile strength, enhanced stiffness, and excellent dimensional stability, making it suitable for structural components requiring rigidity. Carbon-filled plastic, while providing superior strength-to-weight ratios and higher fatigue resistance, also delivers improved electrical conductivity and thermal stability. The choice between these composites depends on the specific mechanical demands, such as load-bearing capacity and weight constraints, in engineering applications.

Weight and Density Differences

Glass-filled plastic typically has a density ranging from 1.5 to 2.0 g/cm3, resulting in moderate weight increases compared to standard plastics, while carbon-filled plastic exhibits lower density values around 1.3 to 1.7 g/cm3, offering a lighter alternative. The higher density of glass-filled composites contributes to increased weight, which can impact applications requiring weight sensitivity. Carbon-filled plastics provide strength with reduced weight, making them preferable for industries like aerospace and automotive where weight savings are critical.

Thermal Resistance and Stability

Glass-filled plastic exhibits enhanced thermal resistance with a heat deflection temperature typically ranging from 120degC to 160degC, making it suitable for applications requiring dimensional stability under moderate heat. Carbon-filled plastic, on the other hand, offers superior thermal stability with heat deflection temperatures often exceeding 180degC, along with improved conductivity for effective heat dissipation. The choice between glass-filled and carbon-filled plastics depends on the specific thermal resistance and stability requirements of high-performance engineering applications.

Chemical Resistance and Durability

Glass-filled plastic exhibits superior chemical resistance against solvents, acids, and alkalis, making it ideal for applications exposed to harsh chemicals. Carbon-filled plastic offers enhanced durability and higher tensile strength, providing excellent wear resistance and dimensional stability under mechanical stress. Both materials improve the base polymer's performance, but glass-filled plastic excels in harsh chemical environments while carbon-filled plastic is preferred for strength-critical components.

Cost Analysis: Glass-Filled vs Carbon-Filled

Glass-filled plastic offers a cost-effective solution with lower material expenses compared to carbon-filled plastic, making it ideal for budget-sensitive applications. Carbon-filled plastic, while more expensive upfront, provides superior strength-to-weight ratios and enhanced conductivity, justifying its higher price in performance-critical industries. Evaluating total lifecycle costs, including durability and functionality, is essential for determining the optimal material choice between glass-filled and carbon-filled plastics.

Common Applications in Industry

Glass-filled plastic is widely used in automotive components, electrical enclosures, and industrial machinery parts due to its enhanced strength and heat resistance. Carbon-filled plastic finds common applications in aerospace, sports equipment, and high-performance electronics where lightweight materials with excellent conductivity and stiffness are critical. Both materials improve mechanical properties but are chosen based on specific industry requirements such as durability versus electrical performance.

Design Considerations and Limitations

Glass-filled plastic offers increased strength and rigidity, making it suitable for components requiring high dimensional stability and impact resistance, but it adds weight and can cause wear on processing tools. Carbon-filled plastic provides superior electrical conductivity and stiffness with lower density, ideal for lightweight structural parts in electronics, yet it may present challenges such as higher cost and potential anisotropy in mechanical properties. Designers must balance strength, weight, conductivity, and manufacturability when choosing between these composites to optimize performance and cost-effectiveness in end-use applications.

Choosing the Right Material for Your Application

Glass-filled plastic offers excellent dimensional stability, high tensile strength, and improved resistance to wear, making it ideal for applications requiring durability and moderate weight. Carbon-filled plastic provides superior stiffness, electrical conductivity, and thermal resistance, suited for advanced engineering applications where lightweight strength and performance are critical. Selecting the right material depends on factors such as mechanical load, electrical insulation needs, environmental conditions, and cost constraints in your specific project.

Glass-Filled Plastic vs Carbon-Filled Plastic Infographic

materialdif.com

materialdif.com