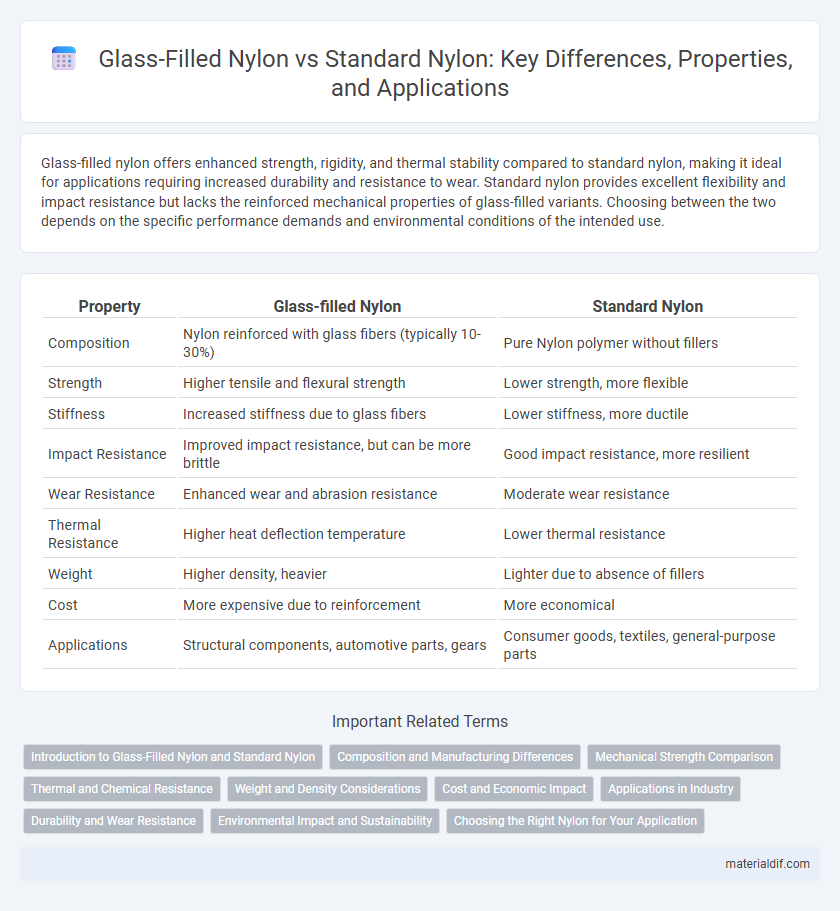

Glass-filled nylon offers enhanced strength, rigidity, and thermal stability compared to standard nylon, making it ideal for applications requiring increased durability and resistance to wear. Standard nylon provides excellent flexibility and impact resistance but lacks the reinforced mechanical properties of glass-filled variants. Choosing between the two depends on the specific performance demands and environmental conditions of the intended use.

Table of Comparison

| Property | Glass-filled Nylon | Standard Nylon |

|---|---|---|

| Composition | Nylon reinforced with glass fibers (typically 10-30%) | Pure Nylon polymer without fillers |

| Strength | Higher tensile and flexural strength | Lower strength, more flexible |

| Stiffness | Increased stiffness due to glass fibers | Lower stiffness, more ductile |

| Impact Resistance | Improved impact resistance, but can be more brittle | Good impact resistance, more resilient |

| Wear Resistance | Enhanced wear and abrasion resistance | Moderate wear resistance |

| Thermal Resistance | Higher heat deflection temperature | Lower thermal resistance |

| Weight | Higher density, heavier | Lighter due to absence of fillers |

| Cost | More expensive due to reinforcement | More economical |

| Applications | Structural components, automotive parts, gears | Consumer goods, textiles, general-purpose parts |

Introduction to Glass-Filled Nylon and Standard Nylon

Glass-filled nylon is a composite material enhanced with glass fibers, significantly increasing its strength, rigidity, and heat resistance compared to standard nylon. Standard nylon, a synthetic polymer known for its excellent wear resistance and flexibility, lacks the enhanced mechanical properties introduced by glass fiber reinforcement. The incorporation of glass fibers in glass-filled nylon offers superior dimensional stability and reduced moisture absorption, making it ideal for demanding engineering applications.

Composition and Manufacturing Differences

Glass-filled nylon consists of standard nylon reinforced with chopped glass fibers, typically ranging from 10% to 50% by weight, enhancing its mechanical strength and thermal stability. Standard nylon, made purely from polyamide polymers such as nylon 6 or nylon 6/6, offers excellent flexibility but lower structural rigidity compared to its glass-filled counterpart. Manufacturing processes for glass-filled nylon involve careful blending and molding techniques to uniformly distribute glass fibers and prevent brittleness, whereas standard nylon requires simpler extrusion or injection molding without fiber reinforcement considerations.

Mechanical Strength Comparison

Glass-filled nylon exhibits significantly higher tensile strength and rigidity compared to standard nylon, making it ideal for load-bearing applications. The inclusion of glass fibers enhances impact resistance and reduces thermal expansion, resulting in improved dimensional stability under stress. Standard nylon offers greater flexibility but lacks the mechanical robustness required for high-performance engineering components.

Thermal and Chemical Resistance

Glass-filled nylon exhibits superior thermal resistance compared to standard nylon, maintaining structural integrity at temperatures up to 250degC, whereas standard nylon typically withstands up to 120degC. Chemically, glass-filled nylon offers enhanced resistance to solvents, oils, and fuels due to its reinforced composite structure, making it ideal for demanding industrial environments. This combination of high thermal stability and chemical resistance significantly extends the lifecycle and performance reliability of glass-filled nylon components.

Weight and Density Considerations

Glass-filled nylon exhibits higher density and increased weight compared to standard nylon due to the incorporation of glass fibers, typically resulting in a density ranging from 1.30 to 1.50 g/cm3 versus standard nylon's 1.02 to 1.15 g/cm3. This enhanced density improves mechanical strength and stiffness but adds significant mass, impacting applications where lightweight materials are crucial. Designers must balance weight considerations against performance needs when selecting between glass-filled nylon and standard nylon for engineering components.

Cost and Economic Impact

Glass-filled nylon typically costs 20-30% more than standard nylon due to the added reinforcement materials and enhanced mechanical properties. The higher initial investment is offset by improved durability and reduced maintenance, resulting in lower long-term operational expenses. Manufacturers benefit economically from glass-filled nylon's superior strength and heat resistance, which extend product lifespan and decrease replacement frequency.

Applications in Industry

Glass-filled nylon offers enhanced mechanical strength, heat resistance, and dimensional stability compared to standard nylon, making it ideal for automotive components, electrical housings, and industrial machinery parts. Its improved stiffness and reduced wear extend the lifespan of gears, bearings, and structural elements in heavy-duty applications. Standard nylon remains preferred for less demanding uses such as consumer goods and lightweight components where flexibility and cost-efficiency are priorities.

Durability and Wear Resistance

Glass-filled nylon exhibits significantly higher durability and wear resistance compared to standard nylon, due to the embedded glass fibers that enhance mechanical strength and reduce deformation under stress. The composite material withstands abrasive environments and repetitive friction more effectively, extending part lifespan in industrial and automotive applications. Standard nylon, while flexible, lacks the reinforced structure necessary for high-load or high-wear scenarios, making glass-filled nylon preferable for performance-critical components.

Environmental Impact and Sustainability

Glass-filled nylon offers enhanced strength and durability compared to standard nylon, reducing the frequency of replacement and minimizing plastic waste in long-term applications. However, the inclusion of glass fibers complicates recycling processes, often requiring specialized treatment that limits end-of-life material recovery. Standard nylon, while less robust, is generally more recyclable and can contribute to lower environmental impact when managed within circular economy systems.

Choosing the Right Nylon for Your Application

Glass-filled nylon offers superior strength, stiffness, and thermal stability compared to standard nylon, making it ideal for high-stress mechanical components and industrial applications. Standard nylon provides excellent flexibility, impact resistance, and abrasion resistance, which suits general-purpose parts and applications requiring moderate durability. Selecting the right nylon depends on balancing mechanical performance requirements, environmental exposure, and cost considerations to optimize functionality and longevity.

Glass-filled Nylon vs Standard Nylon Infographic

materialdif.com

materialdif.com