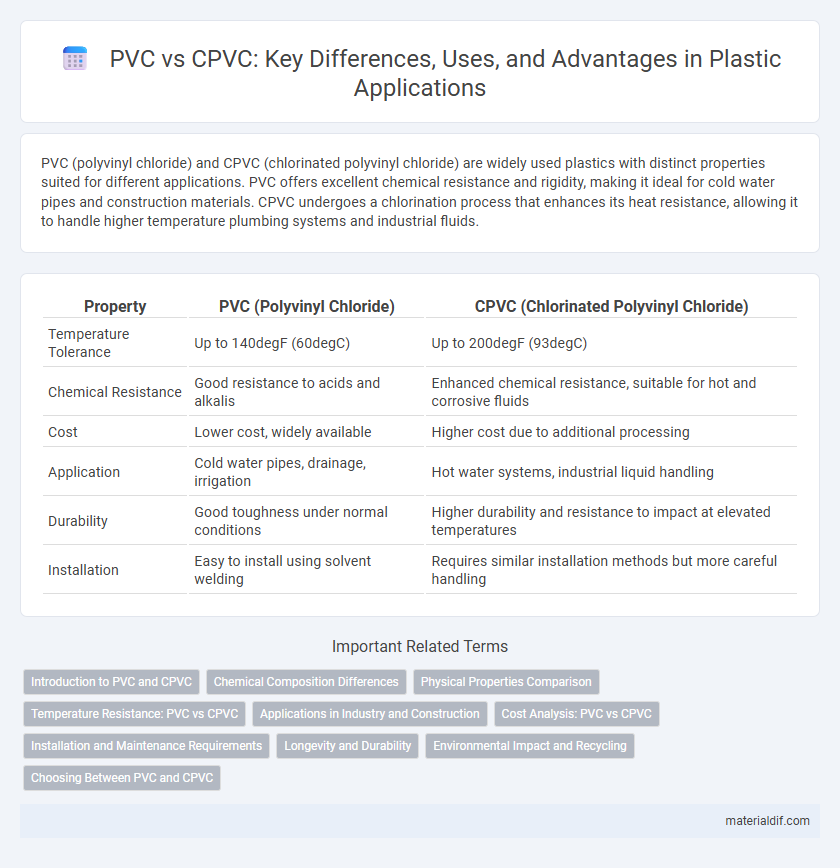

PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) are widely used plastics with distinct properties suited for different applications. PVC offers excellent chemical resistance and rigidity, making it ideal for cold water pipes and construction materials. CPVC undergoes a chlorination process that enhances its heat resistance, allowing it to handle higher temperature plumbing systems and industrial fluids.

Table of Comparison

| Property | PVC (Polyvinyl Chloride) | CPVC (Chlorinated Polyvinyl Chloride) |

|---|---|---|

| Temperature Tolerance | Up to 140degF (60degC) | Up to 200degF (93degC) |

| Chemical Resistance | Good resistance to acids and alkalis | Enhanced chemical resistance, suitable for hot and corrosive fluids |

| Cost | Lower cost, widely available | Higher cost due to additional processing |

| Application | Cold water pipes, drainage, irrigation | Hot water systems, industrial liquid handling |

| Durability | Good toughness under normal conditions | Higher durability and resistance to impact at elevated temperatures |

| Installation | Easy to install using solvent welding | Requires similar installation methods but more careful handling |

Introduction to PVC and CPVC

PVC (Polyvinyl Chloride) is a widely used plastic known for its durability, chemical resistance, and affordability, commonly utilized in piping, construction, and electrical insulation. CPVC (Chlorinated Polyvinyl Chloride) is a thermoplastic derived by chlorinating PVC, enhancing its heat resistance and making it suitable for hot water systems and industrial applications. Both materials offer corrosion resistance and ease of installation, with CPVC providing superior performance in higher temperature environments.

Chemical Composition Differences

PVC (Polyvinyl Chloride) consists primarily of vinyl chloride monomers with a simple structure characterized by repeating units of -(CH2-CHCl)-, making it rigid and widely used in construction. CPVC (Chlorinated Polyvinyl Chloride) undergoes chlorination of PVC, increasing its chlorine content from approximately 56% to about 67%, enhancing thermal stability and chemical resistance. The increased chlorine atoms in CPVC's polymer chain result in improved performance under higher temperatures and corrosive environments compared to standard PVC.

Physical Properties Comparison

PVC (Polyvinyl Chloride) exhibits a tensile strength of approximately 7,000 psi and a maximum operating temperature around 140degF, making it suitable for cold water applications. CPVC (Chlorinated Polyvinyl Chloride) offers enhanced thermal resistance with a maximum service temperature up to 200degF and a slightly higher tensile strength near 8,000 psi, enabling use in hot water and industrial fluid systems. Both materials demonstrate excellent corrosion resistance and chemical stability, but CPVC's improved heat tolerance distinguishes it in high-temperature plumbing environments.

Temperature Resistance: PVC vs CPVC

CPVC exhibits superior temperature resistance compared to PVC, withstanding continuous exposure up to 200degF (93degC) while PVC typically maxes out around 140degF (60degC). This enhanced heat tolerance makes CPVC ideal for hot water plumbing and industrial applications requiring thermal durability. PVC's lower temperature limit restricts its use primarily to cold water and non-heated fluid systems.

Applications in Industry and Construction

PVC (Polyvinyl Chloride) is widely used in general construction for pipes, fittings, and electrical conduit due to its affordability, chemical resistance, and ease of installation. CPVC (Chlorinated Polyvinyl Chloride) is preferred in industrial and construction applications requiring higher temperature resistance and enhanced durability, such as hot water distribution systems and chemical processing plants. Both materials offer corrosion resistance and longevity, but CPVC's elevated temperature threshold up to 200degF makes it ideal for more demanding environments.

Cost Analysis: PVC vs CPVC

PVC pipes generally cost 20-30% less than CPVC pipes, making them a budget-friendly option for many plumbing projects. CPVC offers higher temperature resistance, which can justify its higher price in applications requiring durability under heat stress. Life-cycle costs should be considered, as CPVC's longer lifespan and resistance to corrosion may reduce maintenance and replacement expenses over time.

Installation and Maintenance Requirements

PVC pipes offer simple installation with solvent welding and require minimal maintenance due to their resistance to corrosion and chemical damage. CPVC, while similar in installation methods, demands careful handling during fitting because of its brittleness but offers enhanced durability in high-temperature applications, reducing long-term maintenance needs. Both materials benefit from routine inspections, but CPVC's performance in hot water systems often leads to fewer repair interventions.

Longevity and Durability

PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) both offer high durability, but CPVC demonstrates superior longevity due to its enhanced chemical resistance and ability to withstand higher temperatures up to 200degF. PVC is suitable for cold water and drainage systems as it maintains structural integrity under normal conditions, yet CPVC outperforms in environments requiring long-term exposure to heat and corrosive agents. The molecular chlorine addition in CPVC provides greater thermal stability, resulting in a longer service life for plumbing and industrial applications where durability is critical.

Environmental Impact and Recycling

PVC and CPVC differ in environmental impact primarily due to their chlorine content and thermal stability, with CPVC containing more chlorine, leading to greater challenges in recycling processes. PVC is more widely recycled through established programs, enabling the recovery of raw materials and reduction in landfill waste, whereas CPVC recycling is limited and often results in incineration or disposal. Both materials pose potential environmental risks if not properly managed, but advances in chemical recycling techniques are improving sustainability prospects for PVC over CPVC.

Choosing Between PVC and CPVC

PVC offers excellent chemical resistance and affordability for cold water applications, while CPVC withstands higher temperatures and pressure, making it suitable for hot water systems. Selecting between PVC and CPVC depends on the operating temperature, with PVC rated up to 140degF and CPVC up to 200degF, influencing durability and safety. Consider local building codes and specific use cases, as CPVC is preferred for fire sprinkler systems and industrial piping due to its enhanced thermal performance.

PVC vs CPVC Infographic

materialdif.com

materialdif.com