Copolymers consist of two or more different monomers combined, offering enhanced properties like improved flexibility, chemical resistance, and impact strength compared to homopolymers made from a single monomer type. Homopolymers typically provide uniform characteristics and are easier to process but may lack the specialized performance benefits seen in copolymers. Choosing between copolymers and homopolymers depends on the specific application requirements and desired material properties in plastic manufacturing.

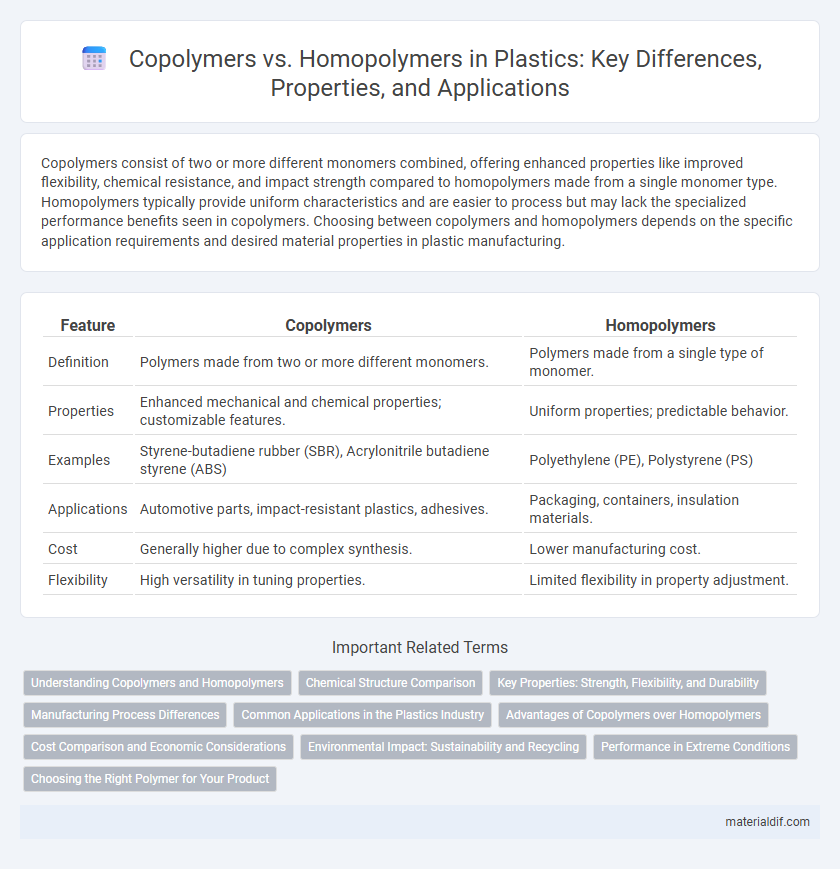

Table of Comparison

| Feature | Copolymers | Homopolymers |

|---|---|---|

| Definition | Polymers made from two or more different monomers. | Polymers made from a single type of monomer. |

| Properties | Enhanced mechanical and chemical properties; customizable features. | Uniform properties; predictable behavior. |

| Examples | Styrene-butadiene rubber (SBR), Acrylonitrile butadiene styrene (ABS) | Polyethylene (PE), Polystyrene (PS) |

| Applications | Automotive parts, impact-resistant plastics, adhesives. | Packaging, containers, insulation materials. |

| Cost | Generally higher due to complex synthesis. | Lower manufacturing cost. |

| Flexibility | High versatility in tuning properties. | Limited flexibility in property adjustment. |

Understanding Copolymers and Homopolymers

Copolymers consist of two or more different monomers chemically bonded, offering tailored properties like enhanced strength, flexibility, or chemical resistance compared to homopolymers, which are made from identical monomers. The molecular structure of copolymers, such as random, block, or graft arrangements, directly influences material performance in applications like packaging, automotive parts, and biomedical devices. Understanding the distinctions in monomer composition and arrangement aids in selecting the appropriate polymer type for specific industrial and commercial uses.

Chemical Structure Comparison

Copolymers consist of two or more different monomer units chemically bonded in the polymer chain, resulting in varied repeating units, whereas homopolymers contain only one type of monomer, producing a uniform repeating structure. The chemical structure of copolymers allows for tailored physical and chemical properties by adjusting the ratio and sequence of monomers, unlike homopolymers that exhibit consistent behavior derived from a single monomer type. This structural diversity in copolymers influences properties such as flexibility, chemical resistance, and thermal stability, which are generally more uniform in homopolymers due to their simpler chemical composition.

Key Properties: Strength, Flexibility, and Durability

Copolymers exhibit enhanced strength and flexibility compared to homopolymers due to the combination of two or more different monomers, which imparts unique molecular arrangements that improve impact resistance and elongation. Homopolymers, consisting of a single monomer type, often offer higher crystallinity and hardness but can lack the versatility in durability and deformation resistance found in copolymers. The tailored properties of copolymers make them ideal for applications requiring a balance of rigidity and toughness, while homopolymers excel in structural roles demanding uniformity and high thermal resistance.

Manufacturing Process Differences

Copolymers are produced through polymerization involving two or more different monomers, resulting in materials with tailored properties by controlling the sequence and ratio of monomers. Homopolymers are synthesized from a single type of monomer, leading to uniform chemical composition and simpler processing conditions. The manufacturing process for copolymers requires more precise control over reaction parameters such as temperature, catalyst selection, and monomer feed rates to achieve the desired copolymer architecture and performance.

Common Applications in the Plastics Industry

Copolymers, composed of two or more monomer types, offer enhanced properties such as improved impact resistance and flexibility, making them ideal for applications like automotive parts, packaging films, and medical devices. Homopolymers, made from a single monomer, provide consistent structural integrity and are commonly used in plastic containers, pipes, and household goods. The plastics industry often selects copolymers for applications requiring advanced mechanical properties and homopolymers for cost-effective, durable solutions.

Advantages of Copolymers over Homopolymers

Copolymers offer enhanced material properties such as improved toughness, flexibility, and chemical resistance compared to homopolymers, making them ideal for specialized applications. The ability to tailor mechanical and thermal characteristics through varying monomer compositions provides greater versatility in manufacturing processes. Copolymers also demonstrate superior impact strength and environmental stress cracking resistance, extending the lifespan of plastic products.

Cost Comparison and Economic Considerations

Copolymers often incur higher production costs than homopolymers due to the complexity of polymerizing two or more monomers, resulting in increased raw material and processing expenses. Homopolymers, derived from a single monomer type like polyethylene or polypropylene, typically offer lower cost advantages and simpler manufacturing routes. Economic considerations favor homopolymers for large-scale, cost-sensitive applications, while copolymers justify their premium price through enhanced material properties and performance in specialized markets.

Environmental Impact: Sustainability and Recycling

Copolymers often exhibit enhanced mechanical and chemical properties compared to homopolymers, leading to increased durability and longer product lifespans, which can reduce overall plastic waste. However, the complexity of copolymer structures frequently complicates recycling processes, as different monomer units may require separate treatment methods, limiting recyclability. Homopolymers, due to their uniform composition, are generally easier to recycle and more compatible with existing recycling infrastructure, supporting more sustainable material recovery.

Performance in Extreme Conditions

Copolymers exhibit superior performance in extreme conditions compared to homopolymers due to their tailored molecular architecture, which combines different monomers to enhance thermal stability, chemical resistance, and mechanical strength. Homopolymers, composed of a single monomer type, often lack the versatility and adaptability required for harsh environments, limiting their application scope. The ability of copolymers to balance stiffness and flexibility makes them ideal for use in automotive, aerospace, and industrial applications where durability under stress and fluctuating temperatures is critical.

Choosing the Right Polymer for Your Product

Selecting the right polymer for your product depends on performance requirements such as flexibility, strength, and chemical resistance. Copolymers, composed of two or more monomers, offer tailored properties like improved impact resistance and durability, making them ideal for versatile applications. Homopolymers, made from a single monomer type, provide consistent mechanical properties and are often preferred for simpler, cost-effective solutions.

Copolymers vs Homopolymers Infographic

materialdif.com

materialdif.com