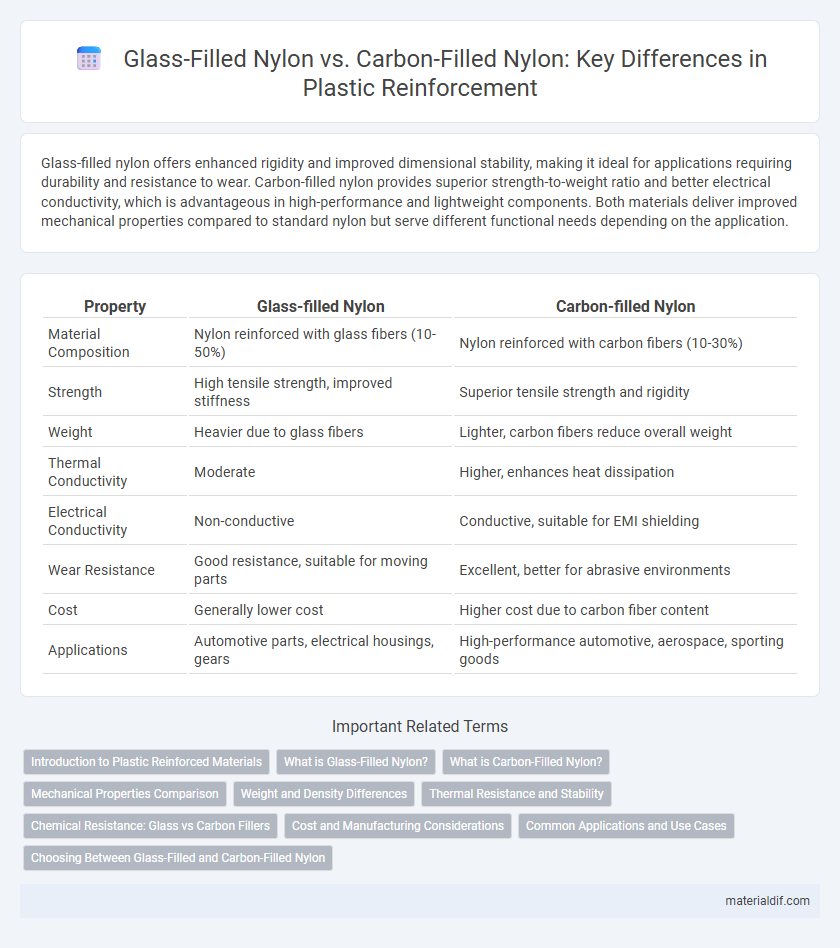

Glass-filled nylon offers enhanced rigidity and improved dimensional stability, making it ideal for applications requiring durability and resistance to wear. Carbon-filled nylon provides superior strength-to-weight ratio and better electrical conductivity, which is advantageous in high-performance and lightweight components. Both materials deliver improved mechanical properties compared to standard nylon but serve different functional needs depending on the application.

Table of Comparison

| Property | Glass-filled Nylon | Carbon-filled Nylon |

|---|---|---|

| Material Composition | Nylon reinforced with glass fibers (10-50%) | Nylon reinforced with carbon fibers (10-30%) |

| Strength | High tensile strength, improved stiffness | Superior tensile strength and rigidity |

| Weight | Heavier due to glass fibers | Lighter, carbon fibers reduce overall weight |

| Thermal Conductivity | Moderate | Higher, enhances heat dissipation |

| Electrical Conductivity | Non-conductive | Conductive, suitable for EMI shielding |

| Wear Resistance | Good resistance, suitable for moving parts | Excellent, better for abrasive environments |

| Cost | Generally lower cost | Higher cost due to carbon fiber content |

| Applications | Automotive parts, electrical housings, gears | High-performance automotive, aerospace, sporting goods |

Introduction to Plastic Reinforced Materials

Glass-filled nylon offers enhanced stiffness, strength, and dimensional stability by embedding glass fibers into the nylon matrix, making it ideal for high-impact and wear-resistant applications. Carbon-filled nylon incorporates carbon fibers, delivering superior electrical conductivity, improved tensile strength, and reduced weight, suitable for advanced engineering uses requiring electrical grounding or static dissipation. Both materials significantly improve the mechanical properties of standard nylon, expanding its functionality across automotive, aerospace, and electronic industries.

What is Glass-Filled Nylon?

Glass-filled nylon is a type of reinforced polymer infused with chopped glass fibers to enhance its mechanical properties. This composite material offers increased tensile strength, improved dimensional stability, and higher resistance to wear and heat compared to standard nylon. Commonly used in automotive, electrical, and industrial applications, glass-filled nylon provides a durable yet lightweight solution for demanding environments.

What is Carbon-Filled Nylon?

Carbon-filled nylon is a composite material combining nylon polymer with carbon fibers, enhancing strength, stiffness, and thermal stability. Its low density and high tensile strength make it ideal for lightweight, durable parts in automotive and aerospace applications. The carbon fiber reinforcement significantly improves wear resistance and reduces the material's coefficient of thermal expansion compared to standard nylon.

Mechanical Properties Comparison

Glass-filled nylon offers excellent tensile strength and impact resistance, making it suitable for applications requiring durability and toughness. Carbon-filled nylon provides superior stiffness and enhanced dimensional stability, ideal for precision engineering components exposed to high stress. Both materials improve mechanical performance over unfilled nylon but differ in balancing strength versus rigidity for specific industrial uses.

Weight and Density Differences

Glass-filled nylon typically has a density ranging from 1.3 to 1.5 g/cm3, making it heavier than carbon-filled nylon, which usually has a density around 1.2 to 1.35 g/cm3. The higher density of glass-filled nylon results from the heavier glass fibers compared to the lighter carbon fibers used in carbon-filled nylon composites. Weight differences between these materials influence their application, with carbon-filled nylon favored for lightweight parts requiring high strength-to-weight ratios.

Thermal Resistance and Stability

Glass-filled Nylon exhibits excellent thermal resistance, maintaining stability up to approximately 120degC, making it suitable for applications requiring moderate heat endurance. Carbon-filled Nylon offers superior thermal stability, withstanding temperatures near 160degC while providing enhanced stiffness and reduced thermal expansion. Both composites improve Nylon's base properties, but Carbon-filled variants deliver higher performance in thermal resistance and dimensional stability under elevated temperatures.

Chemical Resistance: Glass vs Carbon Fillers

Glass-filled nylon offers superior chemical resistance against acids and solvents compared to carbon-filled nylon, making it ideal for harsh chemical environments. Carbon-filled nylon excels in electrical conductivity but can be more susceptible to degradation from certain chemicals. Selecting the appropriate filler depends on the specific chemical exposure and performance requirements in the application.

Cost and Manufacturing Considerations

Glass-filled nylon offers a lower-cost alternative to carbon-filled nylon while still enhancing strength and rigidity in injection molding processes. Manufacturing glass-filled nylon involves straightforward compounding and molding techniques, making it suitable for high-volume production with reduced tooling wear. Carbon-filled nylon, although more expensive, requires specialized equipment to manage abrasive carbon fibers but delivers superior stiffness and thermal conductivity for demanding engineering applications.

Common Applications and Use Cases

Glass-filled nylon is commonly used in automotive components, electrical housings, and industrial machinery due to its enhanced strength and rigidity. Carbon-filled nylon is preferred in high-performance applications such as aerospace, sports equipment, and robotics for its superior stiffness and electrical conductivity. Both materials excel in environments requiring durability and resistance to wear but are chosen based on specific mechanical and thermal property requirements.

Choosing Between Glass-Filled and Carbon-Filled Nylon

When choosing between glass-filled and carbon-filled nylon, consider mechanical strength and weight requirements, as carbon-filled nylon offers higher stiffness and better electrical conductivity while glass-filled nylon provides improved dimensional stability and cost efficiency. Glass-filled nylon excels in applications requiring resistance to wear and fatigue, whereas carbon-filled nylon is preferred for environments demanding lightweight parts with enhanced thermal stability. Evaluating the specific performance needs, such as load-bearing capacity and environmental exposure, ensures optimal material selection for engineering and manufacturing projects.

Glass-filled Nylon vs Carbon-filled Nylon Infographic

materialdif.com

materialdif.com