Cold drawing and hot drawing are two distinct metal forming processes used in the production of plastic pet components, each affecting material properties differently. Cold drawing occurs at room temperature, enhancing tensile strength and surface finish through strain hardening, while hot drawing involves heating the material above its recrystallization temperature to improve ductility and reduce residual stresses. Selecting between cold and hot drawing depends on the desired balance of strength, flexibility, and surface quality in the final plastic pet product.

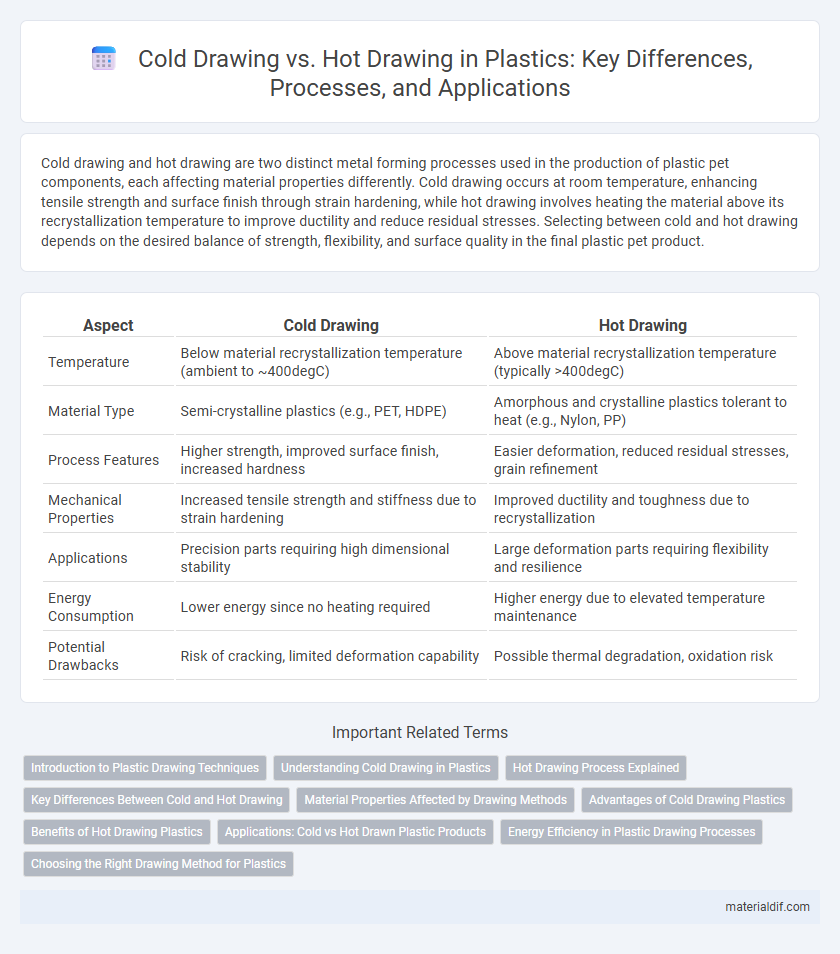

Table of Comparison

| Aspect | Cold Drawing | Hot Drawing |

|---|---|---|

| Temperature | Below material recrystallization temperature (ambient to ~400degC) | Above material recrystallization temperature (typically >400degC) |

| Material Type | Semi-crystalline plastics (e.g., PET, HDPE) | Amorphous and crystalline plastics tolerant to heat (e.g., Nylon, PP) |

| Process Features | Higher strength, improved surface finish, increased hardness | Easier deformation, reduced residual stresses, grain refinement |

| Mechanical Properties | Increased tensile strength and stiffness due to strain hardening | Improved ductility and toughness due to recrystallization |

| Applications | Precision parts requiring high dimensional stability | Large deformation parts requiring flexibility and resilience |

| Energy Consumption | Lower energy since no heating required | Higher energy due to elevated temperature maintenance |

| Potential Drawbacks | Risk of cracking, limited deformation capability | Possible thermal degradation, oxidation risk |

Introduction to Plastic Drawing Techniques

Plastic drawing techniques include cold drawing and hot drawing, which differ primarily in temperature application and material behavior. Cold drawing involves deforming plastic below its glass transition temperature, resulting in increased strength and dimensional accuracy due to strain hardening. Hot drawing is performed above the glass transition temperature, enhancing ductility and allowing easier shaping with less residual stress in the final plastic product.

Understanding Cold Drawing in Plastics

Cold drawing in plastics involves mechanically stretching polymer materials below their glass transition temperature, enhancing molecular orientation and improving tensile strength and stiffness. This process refines the microstructure without significant thermal degradation, resulting in better dimensional stability and surface finish compared to hot drawing. Cold-drawn plastics exhibit increased clarity and resistance to environmental stress cracking, making them ideal for high-performance applications requiring precise mechanical properties.

Hot Drawing Process Explained

Hot drawing in plastics involves shaping the material at elevated temperatures above its glass transition or melting point, enhancing its ductility and reducing internal stresses. This process improves molecular orientation and mechanical properties, resulting in stronger, more dimensionally stable plastic products. Hot drawing is particularly effective for amorphous and semi-crystalline polymers, enabling precise control over tensile strength and elongation.

Key Differences Between Cold and Hot Drawing

Cold drawing involves shaping plastic at or below room temperature, resulting in higher tensile strength and improved surface finish due to strain hardening. Hot drawing processes plastic above its glass transition temperature, allowing for easier deformation and reduced residual stresses, but can lead to lower dimensional accuracy. The choice between cold and hot drawing depends on the desired mechanical properties, surface quality, and dimensional tolerances of the final plastic product.

Material Properties Affected by Drawing Methods

Cold drawing enhances plastic's tensile strength, hardness, and surface finish by inducing strain hardening without altering its inherent polymer structure. Hot drawing, performed above the polymer's glass transition temperature, improves ductility and reduces internal stresses by allowing molecular chains to realign more easily. The choice between cold and hot drawing significantly impacts mechanical properties like elongation, modulus of elasticity, and impact resistance in plastics.

Advantages of Cold Drawing Plastics

Cold drawing plastics enhances tensile strength and dimensional accuracy due to strain hardening at lower temperatures. This process improves surface finish and reduces internal stresses without causing thermal degradation or warping. Cold-drawn plastics also exhibit superior mechanical properties, making them ideal for high-performance applications requiring precise tolerances.

Benefits of Hot Drawing Plastics

Hot drawing plastics enhances molecular alignment and crystallinity, resulting in superior mechanical strength and improved thermal resistance. The elevated temperature during hot drawing reduces internal stresses and allows for greater elongation without compromising integrity. This process also promotes uniform material flow, which enhances dimensional stability and surface finish in the final plastic product.

Applications: Cold vs Hot Drawn Plastic Products

Cold drawing of plastics produces products with enhanced strength and dimensional accuracy, ideal for precision components such as electrical insulation parts, films, and tubes. Hot drawing allows for greater flexibility in shaping complex geometries and is commonly used in manufacturing large plastic sheets, pipes, and containers requiring uniform thickness. Applications of cold drawn plastics emphasize mechanical performance and tight tolerances, while hot drawing suits bulk production where thermal formability is critical.

Energy Efficiency in Plastic Drawing Processes

Cold drawing in plastic processing consumes less energy compared to hot drawing due to the absence of heating requirements, reducing overall power consumption and carbon emissions. Hot drawing involves elevated temperatures that increase thermal energy demands, resulting in higher operational costs and energy usage. Selecting cold drawing optimizes energy efficiency by minimizing heat input while maintaining material integrity and mechanical properties.

Choosing the Right Drawing Method for Plastics

Cold drawing enhances the tensile strength and dimensional accuracy of plastics by deforming the material below its glass transition temperature, making it ideal for applications requiring precise mechanical properties and surface finish. Hot drawing softens the plastic above its glass transition temperature, allowing greater elongation and reduced residual stresses, suitable for complex shapes or large-scale production. Selecting the appropriate drawing method depends on the plastic type, desired mechanical characteristics, and final product specifications.

Cold Drawing vs Hot Drawing Infographic

materialdif.com

materialdif.com