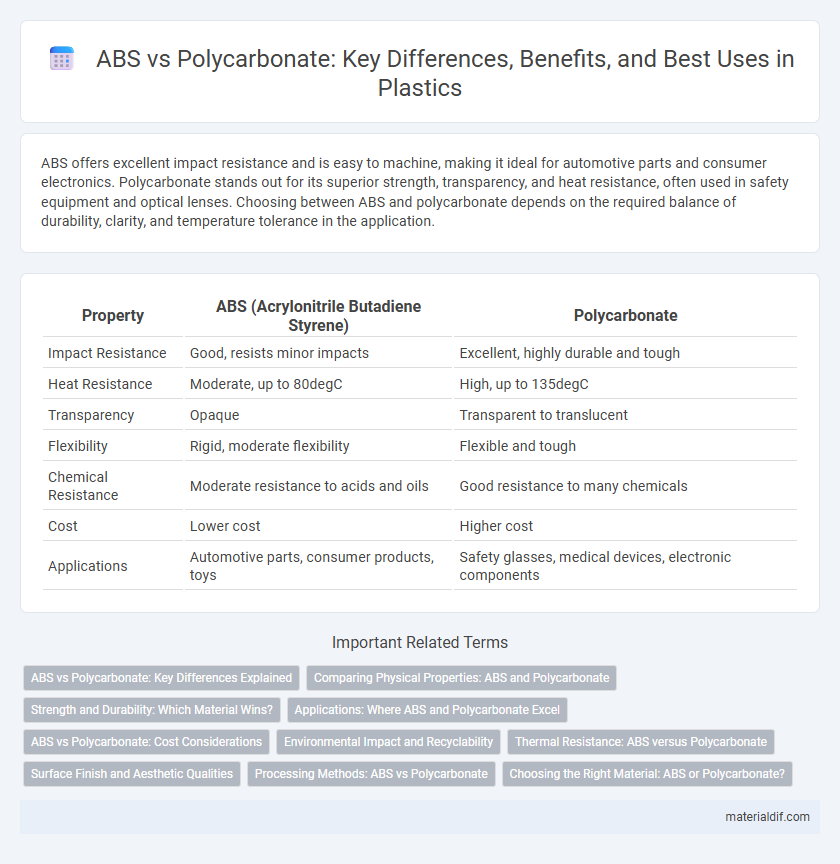

ABS offers excellent impact resistance and is easy to machine, making it ideal for automotive parts and consumer electronics. Polycarbonate stands out for its superior strength, transparency, and heat resistance, often used in safety equipment and optical lenses. Choosing between ABS and polycarbonate depends on the required balance of durability, clarity, and temperature tolerance in the application.

Table of Comparison

| Property | ABS (Acrylonitrile Butadiene Styrene) | Polycarbonate |

|---|---|---|

| Impact Resistance | Good, resists minor impacts | Excellent, highly durable and tough |

| Heat Resistance | Moderate, up to 80degC | High, up to 135degC |

| Transparency | Opaque | Transparent to translucent |

| Flexibility | Rigid, moderate flexibility | Flexible and tough |

| Chemical Resistance | Moderate resistance to acids and oils | Good resistance to many chemicals |

| Cost | Lower cost | Higher cost |

| Applications | Automotive parts, consumer products, toys | Safety glasses, medical devices, electronic components |

ABS vs Polycarbonate: Key Differences Explained

ABS offers excellent impact resistance and ease of machining, making it ideal for automotive and consumer electronics applications, while polycarbonate provides superior optical clarity and higher heat resistance suited for eyewear lenses and bulletproof glass. The density of ABS typically ranges around 1.04 g/cm3, whereas polycarbonate is slightly denser at approximately 1.2 g/cm3, contributing to its enhanced strength and durability. Chemical resistance varies; ABS resists acids and alkalis but is vulnerable to solvents, whereas polycarbonate withstands many environmental factors but can be sensitive to UV light without stabilization.

Comparing Physical Properties: ABS and Polycarbonate

ABS (Acrylonitrile Butadiene Styrene) exhibits excellent impact resistance and rigidity while maintaining a lower density of approximately 1.04 g/cm3, making it lightweight and durable for automotive and consumer goods. Polycarbonate offers superior impact strength, higher heat resistance up to 150degC, and greater optical transparency with a density around 1.2 g/cm3, ideal for applications requiring toughness and clarity like safety goggles and electronic components. Both materials differ in UV resistance and chemical stability, with polycarbonate generally outperforming ABS in toughness and thermal endurance.

Strength and Durability: Which Material Wins?

ABS exhibits high impact resistance and toughness, making it ideal for applications requiring durability under stress. Polycarbonate surpasses ABS with superior strength, exceptional impact resistance, and higher heat tolerance, making it the preferred choice for demanding environments. When comparing strength and durability, polycarbonate is the material winner due to its enhanced mechanical properties and resilience.

Applications: Where ABS and Polycarbonate Excel

ABS is widely used in automotive parts, consumer electronics housings, and LEGO bricks due to its excellent impact resistance and ease of machining, making it ideal for applications requiring durability and aesthetic appeal. Polycarbonate excels in high-performance applications such as safety helmets, bulletproof glass, and optical lenses because of its superior toughness, transparency, and heat resistance. Both plastics serve critical roles in industries where strength and durability are paramount, but polycarbonate is preferred for clear, high-impact, and heat-resistant uses while ABS is favored for cost-effective, sturdy, and versatile products.

ABS vs Polycarbonate: Cost Considerations

ABS offers a lower cost option compared to polycarbonate, making it ideal for budget-sensitive projects requiring moderate strength and impact resistance. Polycarbonate commands a higher price due to superior durability, high impact resistance, and optical clarity, often justified in applications demanding enhanced performance. Evaluating total lifecycle expenses, including fabrication and potential replacements, is crucial when choosing between ABS and polycarbonate materials.

Environmental Impact and Recyclability

ABS plastic generates more environmental pollution due to its petroleum-based production and releases harmful emissions when burned, whereas polycarbonate offers better recyclability through established industrial processes like chemical recycling. Polycarbonate's durability extends product life, reducing waste generation compared to ABS, which tends to degrade faster and requires more frequent replacement. Both plastics face challenges in recycling, but polycarbonate can be efficiently reprocessed into high-quality materials, contributing to a lower environmental footprint.

Thermal Resistance: ABS versus Polycarbonate

ABS offers moderate thermal resistance, typically with a heat deflection temperature around 100degC, making it suitable for general applications with low to medium heat exposure. Polycarbonate exhibits superior thermal resistance, with a heat deflection temperature close to 140degC, allowing it to retain mechanical properties under higher temperatures. This makes polycarbonate a preferred choice in applications demanding increased heat resistance and durability.

Surface Finish and Aesthetic Qualities

ABS offers a smooth surface finish with excellent paint adhesion, making it ideal for applications requiring vibrant colors and detailed textures. Polycarbonate provides a glossy, high-impact resistant surface that maintains clarity and is often used where transparency and toughness are essential. Both materials support customization, but ABS excels in matte finishes while polycarbonate is favored for its superior optical properties and scratch resistance.

Processing Methods: ABS vs Polycarbonate

ABS plastic typically undergoes injection molding and extrusion, offering excellent dimensional stability and ease of secondary operations like machining and gluing. Polycarbonate processing involves injection molding and thermoforming, with high heat resistance allowing for complex shapes and precise optical properties. Both polymers demand specific temperature controls to prevent degradation, with ABS processing temperatures generally ranging from 210degC to 250degC, while polycarbonate requires higher ranges around 280degC to 320degC.

Choosing the Right Material: ABS or Polycarbonate?

ABS offers excellent impact resistance and is more cost-effective, making it ideal for applications requiring toughness and affordability such as automotive parts and consumer electronics housings. Polycarbonate provides superior clarity, higher heat resistance, and greater strength, suited for applications demanding transparency and durability like eyewear lenses and protective gear. Selecting between ABS and polycarbonate depends on specific project requirements including mechanical properties, aesthetic needs, and environmental exposure.

ABS vs Polycarbonate Infographic

materialdif.com

materialdif.com