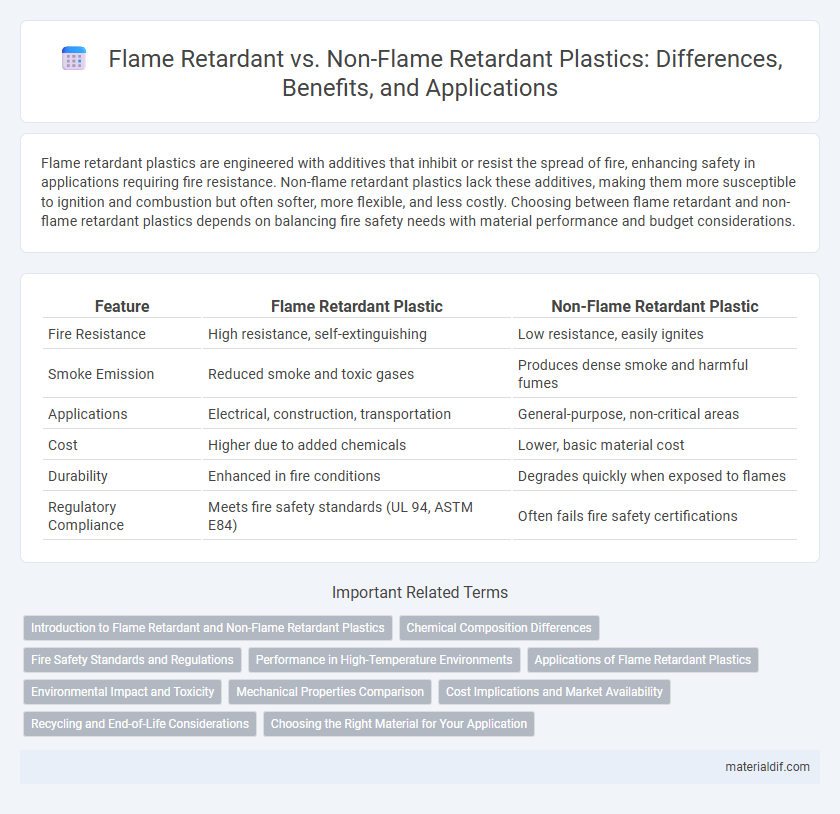

Flame retardant plastics are engineered with additives that inhibit or resist the spread of fire, enhancing safety in applications requiring fire resistance. Non-flame retardant plastics lack these additives, making them more susceptible to ignition and combustion but often softer, more flexible, and less costly. Choosing between flame retardant and non-flame retardant plastics depends on balancing fire safety needs with material performance and budget considerations.

Table of Comparison

| Feature | Flame Retardant Plastic | Non-Flame Retardant Plastic |

|---|---|---|

| Fire Resistance | High resistance, self-extinguishing | Low resistance, easily ignites |

| Smoke Emission | Reduced smoke and toxic gases | Produces dense smoke and harmful fumes |

| Applications | Electrical, construction, transportation | General-purpose, non-critical areas |

| Cost | Higher due to added chemicals | Lower, basic material cost |

| Durability | Enhanced in fire conditions | Degrades quickly when exposed to flames |

| Regulatory Compliance | Meets fire safety standards (UL 94, ASTM E84) | Often fails fire safety certifications |

Introduction to Flame Retardant and Non-Flame Retardant Plastics

Flame retardant plastics contain chemical additives that inhibit or resist the spread of fire, enhancing safety in applications requiring stringent fire protection standards. Non-flame retardant plastics lack these additives, making them more susceptible to ignition and rapid combustion under high temperatures. Selecting between flame retardant and non-flame retardant plastics depends on regulatory requirements, end-use environments, and performance criteria related to fire safety.

Chemical Composition Differences

Flame retardant plastics incorporate chemical additives such as brominated compounds, phosphorus-based agents, or metal hydroxides like aluminum trihydrate to inhibit combustion by disrupting the chemical reactions during a fire. Non-flame retardant plastics lack these specific chemical additives, resulting in higher flammability and faster ignition times. The presence of flame retardant chemicals significantly alters the polymer's thermal degradation pathway, enhancing fire resistance and reducing smoke production.

Fire Safety Standards and Regulations

Flame retardant plastics comply with stringent fire safety standards such as UL 94, FMVSS 302, and EN 13501-1, effectively reducing flammability and smoke production in critical applications. Non-flame retardant plastics lack these fire-resistant properties, making them unsuitable for environments with strict regulatory requirements and increasing the risk of rapid fire spread. Regulatory bodies mandate the use of flame retardant materials in sectors like construction, automotive, and electronics to ensure compliance with fire prevention and safety protocols.

Performance in High-Temperature Environments

Flame retardant plastics exhibit superior thermal stability and resist ignition or self-extinguish when exposed to high temperatures, enhancing safety in critical applications. Non-flame retardant plastics tend to degrade, melt, or combust rapidly under heat, compromising structural integrity and increasing fire hazards. Performance in high-temperature environments is crucial for selecting materials in electronics, automotive, and construction industries where fire resistance and durability are imperative.

Applications of Flame Retardant Plastics

Flame retardant plastics are extensively used in electronics, construction, and automotive industries due to their ability to resist ignition and slow the spread of fire, enhancing safety in critical applications. These materials are essential in manufacturing circuit boards, insulation panels, and interior vehicle components where fire risk must be minimized. Non-flame retardant plastics, while suitable for general consumer goods, lack the specialized additives that provide fire resistance, limiting their use in fire-sensitive environments.

Environmental Impact and Toxicity

Flame retardant plastics often contain brominated or chlorinated compounds that can release toxic dioxins and persistent organic pollutants (POPs) during production, use, or disposal, significantly impacting environmental health. Non-flame retardant plastics generally have a lower immediate toxicity profile but may contribute to increased fire hazards, leading to uncontrolled toxic emissions from combustion. The environmental impact of flame retardants is compounded by their bioaccumulative potential and resistance to degradation, increasing long-term ecosystem toxicity and human health risks.

Mechanical Properties Comparison

Flame retardant plastics typically exhibit reduced mechanical strength and impact resistance compared to non-flame retardant variants due to the incorporation of additives that can alter the polymer matrix. Non-flame retardant plastics often maintain higher tensile strength and elongation at break, making them more suitable for applications requiring durability and flexibility. The trade-off between fire safety and mechanical performance is a critical consideration in material selection for engineering and manufacturing uses.

Cost Implications and Market Availability

Flame retardant plastics generally incur higher costs due to the inclusion of specialized additives that enhance fire resistance, impacting raw material and processing expenses. Non-flame retardant plastics offer cost advantages with simpler formulations but may limit use in safety-critical applications. Market availability favors non-flame retardant variants for general-purpose plastics, while flame retardant versions occupy niche segments in electronics, construction, and automotive industries due to stringent fire safety regulations.

Recycling and End-of-Life Considerations

Flame retardant plastics often contain chemical additives that complicate recycling processes, requiring specialized facilities to safely handle and separate hazardous components, thus increasing overall recycling costs and environmental impact. Non-flame retardant plastics, lacking these additives, are generally easier to recycle and more compatible with standard mechanical recycling systems, facilitating higher material recovery rates and reduced contamination risks. At end-of-life, flame retardant plastics pose greater challenges for waste management and disposal due to potential toxicity and regulatory restrictions, whereas non-flame retardant plastics offer more straightforward pathways for reuse and recycling.

Choosing the Right Material for Your Application

Flame retardant plastics contain additives that significantly reduce fire risk by inhibiting ignition and slowing flame spread, making them ideal for applications in electronics, construction, and transportation where safety is critical. Non-flame retardant plastics lack these additives, offering cost advantages and greater color options but are suitable only for low-risk environments without strict fire safety regulations. Selecting the right material depends on balancing fire safety requirements, regulatory compliance, cost constraints, and the specific conditions of the intended application.

Flame Retardant vs Non-Flame Retardant Infographic

materialdif.com

materialdif.com