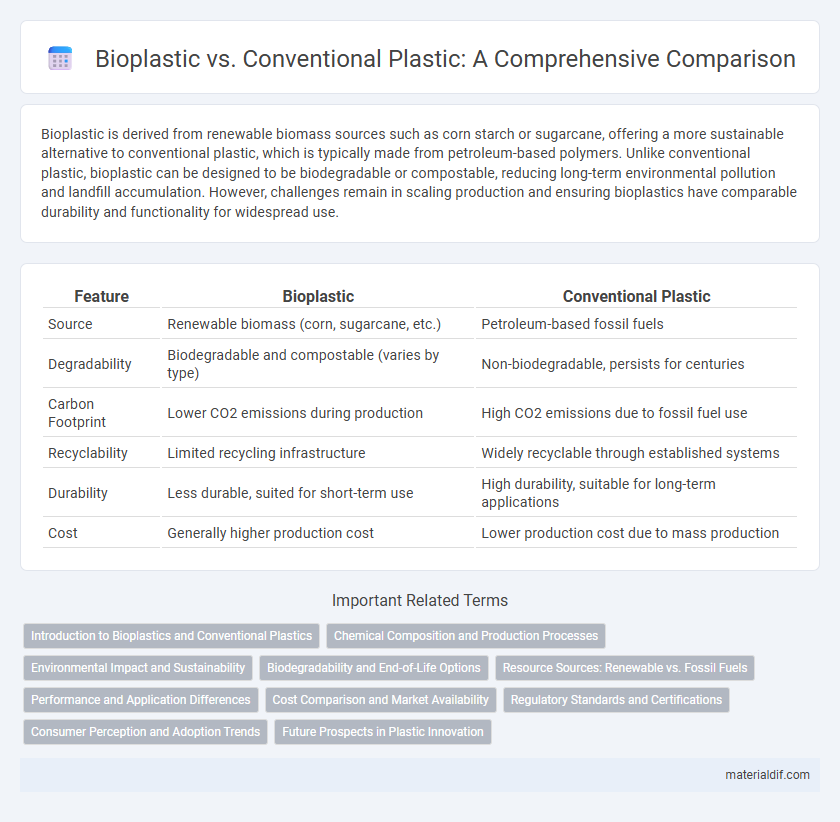

Bioplastic is derived from renewable biomass sources such as corn starch or sugarcane, offering a more sustainable alternative to conventional plastic, which is typically made from petroleum-based polymers. Unlike conventional plastic, bioplastic can be designed to be biodegradable or compostable, reducing long-term environmental pollution and landfill accumulation. However, challenges remain in scaling production and ensuring bioplastics have comparable durability and functionality for widespread use.

Table of Comparison

| Feature | Bioplastic | Conventional Plastic |

|---|---|---|

| Source | Renewable biomass (corn, sugarcane, etc.) | Petroleum-based fossil fuels |

| Degradability | Biodegradable and compostable (varies by type) | Non-biodegradable, persists for centuries |

| Carbon Footprint | Lower CO2 emissions during production | High CO2 emissions due to fossil fuel use |

| Recyclability | Limited recycling infrastructure | Widely recyclable through established systems |

| Durability | Less durable, suited for short-term use | High durability, suitable for long-term applications |

| Cost | Generally higher production cost | Lower production cost due to mass production |

Introduction to Bioplastics and Conventional Plastics

Bioplastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, offering a more sustainable alternative to conventional plastics made from fossil fuels like petroleum and natural gas. Unlike traditional plastics, bioplastics can be biodegradable or compostable, reducing environmental pollution and reliance on non-renewable resources. The global market for bioplastics is rapidly expanding, driven by increasing environmental regulations and consumer demand for eco-friendly materials.

Chemical Composition and Production Processes

Bioplastics are primarily derived from renewable biomass sources such as corn starch, sugarcane, or cellulose, containing polymers like polylactic acid (PLA) or polyhydroxyalkanoates (PHA). Conventional plastics are synthesized from fossil fuels through polymerization of petrochemicals such as ethylene and propylene, resulting in polymers like polyethylene (PE) and polypropylene (PP). Production of bioplastics involves fermentation or enzymatic processes converting biomass into monomers, whereas conventional plastics rely on high-temperature cracking and catalytic polymerization of hydrocarbons.

Environmental Impact and Sustainability

Bioplastic significantly reduces environmental impact by being derived from renewable plant-based sources, which lowers carbon emissions and decreases dependence on fossil fuels. Unlike conventional plastic, which persists in ecosystems for hundreds of years, bioplastics typically offer enhanced biodegradability and compostability, promoting a circular economy. However, large-scale bioplastic production requires sustainable agricultural practices to avoid negative effects on land use and biodiversity.

Biodegradability and End-of-Life Options

Bioplastics offer enhanced biodegradability compared to conventional plastics, breaking down more efficiently under industrial composting conditions or even in home compost setups. Conventional plastics often persist in environments for hundreds of years due to their non-biodegradable nature, leading to significant ecological harm. End-of-life options for bioplastics include composting and anaerobic digestion, while conventional plastics primarily rely on recycling or landfill disposal, which poses greater environmental challenges.

Resource Sources: Renewable vs. Fossil Fuels

Bioplastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, reducing reliance on finite fossil fuels. Conventional plastics primarily depend on petrochemicals extracted from non-renewable fossil fuels like crude oil and natural gas. The shift towards bioplastics supports sustainability by lowering greenhouse gas emissions and conserving limited fossil fuel reserves.

Performance and Application Differences

Bioplastics, derived from renewable biomass sources such as corn starch and sugarcane, offer comparable mechanical properties to conventional plastics in packaging, agriculture, and consumer goods but often exhibit lower thermal resistance and moisture barrier performance. Conventional plastics, primarily petroleum-based polymers like polyethylene and polypropylene, provide superior durability, flexibility, and chemical resistance essential for automotive parts, electronics, and heavy-duty packaging. The application differences hinge on bioplastics' biodegradability and compostability, favoring short-term use and sustainable disposal, whereas conventional plastics dominate in long-lasting, high-strength energy and industrial sectors.

Cost Comparison and Market Availability

Bioplastics typically cost 20-50% more than conventional plastics due to higher raw material and production expenses, limiting their widespread adoption. Conventional plastics dominate global markets with over 350 million tons produced annually, benefiting from established manufacturing infrastructure and lower prices. Despite higher costs, bioplastics are becoming increasingly available in niches like packaging and agriculture as consumer demand for sustainable materials grows.

Regulatory Standards and Certifications

Bioplastics are increasingly subject to regulatory standards such as ASTM D6400 and EN 13432, which certify their compostability and biodegradability, distinguishing them from conventional plastics that typically lack such eco-friendly certifications. Conventional plastics primarily comply with standards like FDA regulations for food contact but rarely meet stringent environmental certifications due to their petroleum-based composition. Regulatory bodies globally are advancing policies encouraging bioplastic certification to reduce environmental impact and improve waste management practices.

Consumer Perception and Adoption Trends

Consumer perception of bioplastics centers on their environmental benefits, with many viewing them as a sustainable alternative to conventional plastics derived from fossil fuels. Adoption trends indicate a growing preference for bioplastics in packaging and disposable products, driven by increased environmental awareness and regulatory incentives promoting biodegradable materials. Despite this, challenges such as higher costs and limited recycling infrastructure continue to hinder widespread consumer transition from conventional plastics to bioplastics.

Future Prospects in Plastic Innovation

Bioplastic development shows significant promise for reducing environmental impact due to its biodegradability and renewable resource base, contrasting with the persistent pollution challenges of conventional plastic derived from fossil fuels. Advances in biopolymer technology and scalable manufacturing processes are accelerating the potential for bioplastics to replace traditional plastics in packaging, agriculture, and consumer goods. Continued investment in research, coupled with regulatory support, is poised to transform the plastic industry towards sustainable solutions with improved lifecycle performance and circular economy integration.

Bioplastic vs Conventional Plastic Infographic

materialdif.com

materialdif.com