Plastic extrusion continuously melts raw plastic material and shapes it through a die to create long, uniform profiles such as pipes, sheets, or films with consistent cross-sections. Plastic injection molding injects molten plastic into a mold cavity to produce complex, high-precision parts in large volumes with intricate details. Choosing between extrusion and injection depends on the desired product shape, production speed, and material efficiency.

Table of Comparison

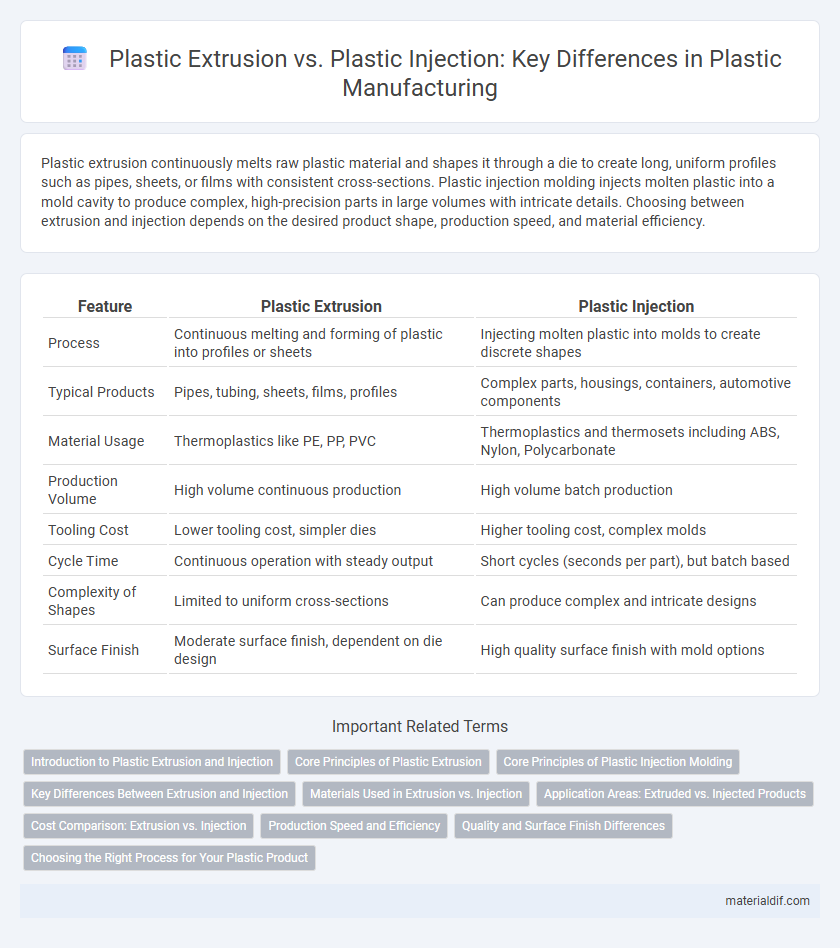

| Feature | Plastic Extrusion | Plastic Injection |

|---|---|---|

| Process | Continuous melting and forming of plastic into profiles or sheets | Injecting molten plastic into molds to create discrete shapes |

| Typical Products | Pipes, tubing, sheets, films, profiles | Complex parts, housings, containers, automotive components |

| Material Usage | Thermoplastics like PE, PP, PVC | Thermoplastics and thermosets including ABS, Nylon, Polycarbonate |

| Production Volume | High volume continuous production | High volume batch production |

| Tooling Cost | Lower tooling cost, simpler dies | Higher tooling cost, complex molds |

| Cycle Time | Continuous operation with steady output | Short cycles (seconds per part), but batch based |

| Complexity of Shapes | Limited to uniform cross-sections | Can produce complex and intricate designs |

| Surface Finish | Moderate surface finish, dependent on die design | High quality surface finish with mold options |

Introduction to Plastic Extrusion and Injection

Plastic extrusion involves melting raw plastic material and continuously shaping it through a die to create long profiles such as pipes, sheets, and films, ideal for high-volume production. Plastic injection molding injects molten plastic into a mold cavity to produce complex and precise parts with intricate details, commonly used in automotive and consumer goods industries. Both processes utilize thermoplastic polymers but differ significantly in production speed, product complexity, and application suitability.

Core Principles of Plastic Extrusion

Plastic extrusion relies on continuous melting and shaping of thermoplastic materials through a heated barrel and screw mechanism, producing uniform profiles like pipes, sheets, and films. The process emphasizes consistent material flow and precise temperature control to ensure high-quality, dimensionally stable outputs. Unlike injection molding, extrusion is ideal for long, continuous shapes rather than complex geometries or molded parts.

Core Principles of Plastic Injection Molding

Plastic injection molding operates by heating plastic pellets until molten, then forcefully injecting the material into a precisely designed steel mold under high pressure, ensuring complex shapes and detailed features are accurately formed. The core principles involve controlling temperature, pressure, and cooling rates to achieve consistent part quality and structural integrity. This process contrasts with plastic extrusion, which continuously forms products by pushing molten plastic through a shaped die rather than filling a closed mold.

Key Differences Between Extrusion and Injection

Plastic extrusion involves forcing molten plastic through a shaped die to create continuous profiles like pipes and sheets, while plastic injection molding injects molten plastic into a mold cavity to produce discrete, complex parts with high precision. Extrusion is ideal for creating uniform cross-sectional shapes and long runs, whereas injection molding excels in producing detailed components with varied geometries and fine surface finishes. Cycle times differ significantly, with extrusion offering continuous production and injection molding requiring individual mold filling and cooling phases.

Materials Used in Extrusion vs. Injection

Plastic extrusion commonly uses thermoplastics such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) due to their ability to be melted and continuously shaped. Injection molding typically employs a broader range of materials, including acrylonitrile butadiene styrene (ABS), polystyrene (PS), and nylon (PA), which offer high precision and complex geometries. The selection of materials in extrusion favors those with good flow properties for continuous processing, while injection molding materials prioritize strength, detail, and surface finish.

Application Areas: Extruded vs. Injected Products

Extruded plastic products are commonly used in applications such as pipes, tubing, weather stripping, and window frames due to their continuous, uniform cross-sections. Injected plastic products are preferred for complex, high-precision items like automotive components, consumer goods, and medical devices, where intricate shapes and tight tolerances are required. The choice between extrusion and injection molding depends largely on product geometry, production volume, and functional requirements in industries like construction, automotive, and electronics.

Cost Comparison: Extrusion vs. Injection

Plastic extrusion generally offers lower initial tooling costs compared to plastic injection molding, making it more cost-effective for producing continuous profiles or simpler shapes. Injection molding, while involving higher upfront mold expenses, becomes more economical for high-volume production runs due to faster cycle times and greater precision. Overall, extrusion suits large-scale manufacturing of uniform cross-sections at a lower unit cost, whereas injection molding better serves complex parts where detailed features justify the higher initial investment.

Production Speed and Efficiency

Plastic extrusion offers continuous production with high throughput, making it ideal for manufacturing long, uniform profiles like pipes and sheets at fast rates. Plastic injection molding excels in producing complex, precise parts with rapid cycle times, optimized for high-volume runs and minimal material waste. Injection molding typically achieves faster production cycles per part, while extrusion provides superior efficiency for continuous, high-speed output of simple cross-sectional shapes.

Quality and Surface Finish Differences

Plastic extrusion produces continuous profiles with consistent surface finish ideal for products like pipes and sheets, while plastic injection molding offers higher precision and superior surface quality suited for complex, detailed parts. Injection molding achieves tighter tolerances and smoother finishes due to the controlled cooling within molds, enhancing aesthetic appeal and dimensional accuracy. Extrusion surfaces may show slight textural variations but excel in uniformity over long runs, making it less suitable for intricate designs requiring fine detail.

Choosing the Right Process for Your Plastic Product

Selecting the right manufacturing process between plastic extrusion and plastic injection molding depends on the design complexity and production volume of your plastic product. Plastic extrusion is ideal for creating continuous profiles such as pipes and sheets with consistent cross-sections, while injection molding excels in producing intricate, high-precision parts with detailed features. Considering factors like material compatibility, cycle time, and tooling costs ensures optimal performance and cost-efficiency in your plastic product development.

Plastic Extrusion vs Plastic Injection Infographic

materialdif.com

materialdif.com